System and method for detecting surface defect on glass panel

A technology of glass panels and detection methods, applied in measuring devices, instruments, and material analysis through optical means, can solve the problems of phase measurement errors, inability to distinguish gradients and heights, etc., to overcome measurement errors and eliminate system ambiguity , the effect of reducing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

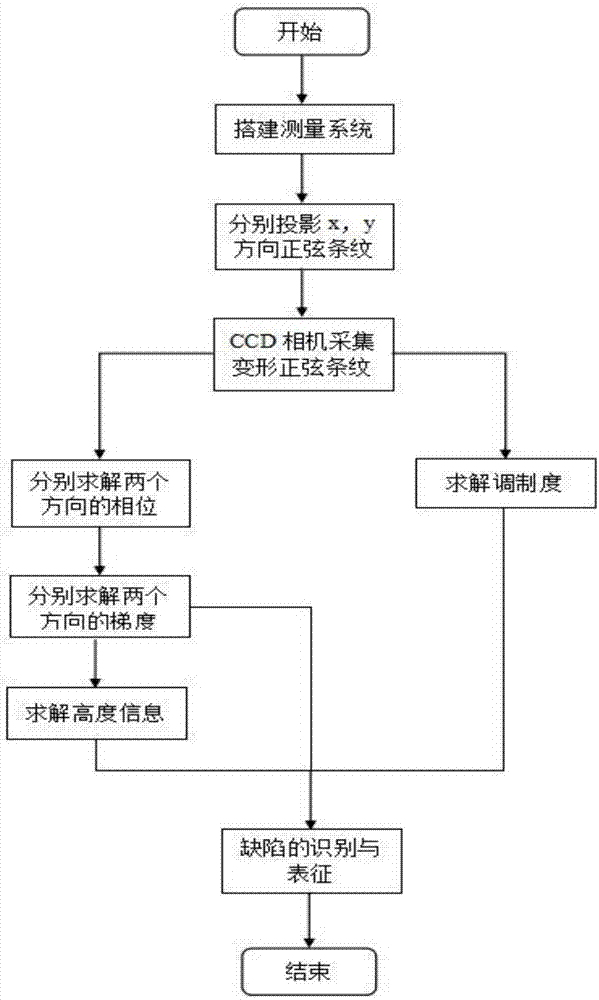

Method used

Image

Examples

Embodiment

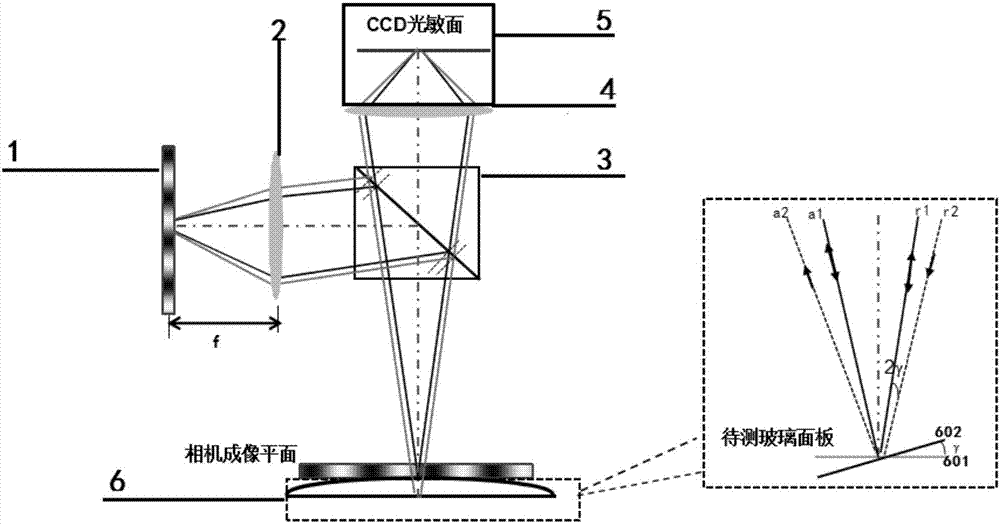

[0052] Such as figure 1 Shown is the system for detecting surface defects of a glass panel according to the present invention, which includes: a coded surface structured light display device 1, a lens 2, a telecentric lens 4, a beam splitter 3, an image acquisition device 5 and an image processing device;

[0053] The positional relationship in space between the encoding surface structured light display device 1, the beam splitter 3, the glass panel surface to be tested 6 and the image acquisition device 5 satisfies the law of reflection, wherein: the image acquisition device 5 is set on the surface 6 with the glass panel to be tested. Above, the image acquisition device 5 is equipped with an object-space telecentric lens to form a telecentric optical path, and the beam splitter 3 is installed between the image acquisition device 5 and the surface 6 of the glass panel to be tested at an inclination of 45 degrees, so that the system ambiguity is minimized, and the encoding A le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com