Rotary flexible beam rigidness and softness coupling system vibration measuring and controlling device and method

A rigid-flexible coupling and rotation-flexible technology, which is applied in measuring devices, vibration testing, and machine/structural component testing, can solve problems that threaten spacecraft operation safety, system performance degradation, and affect spacecraft performance. The effect of low energy consumption and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

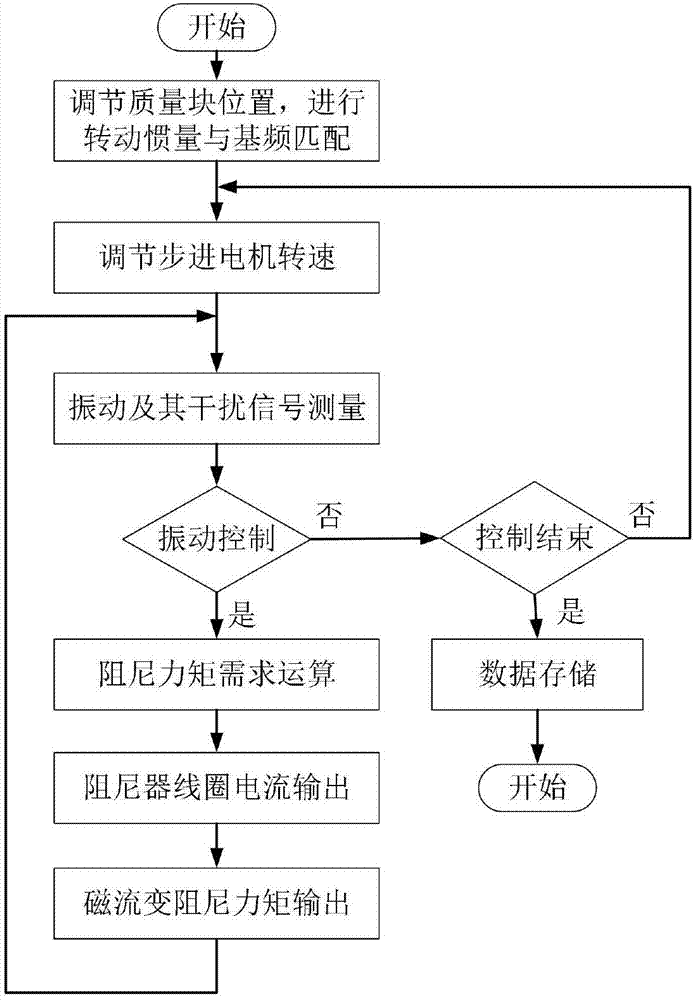

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

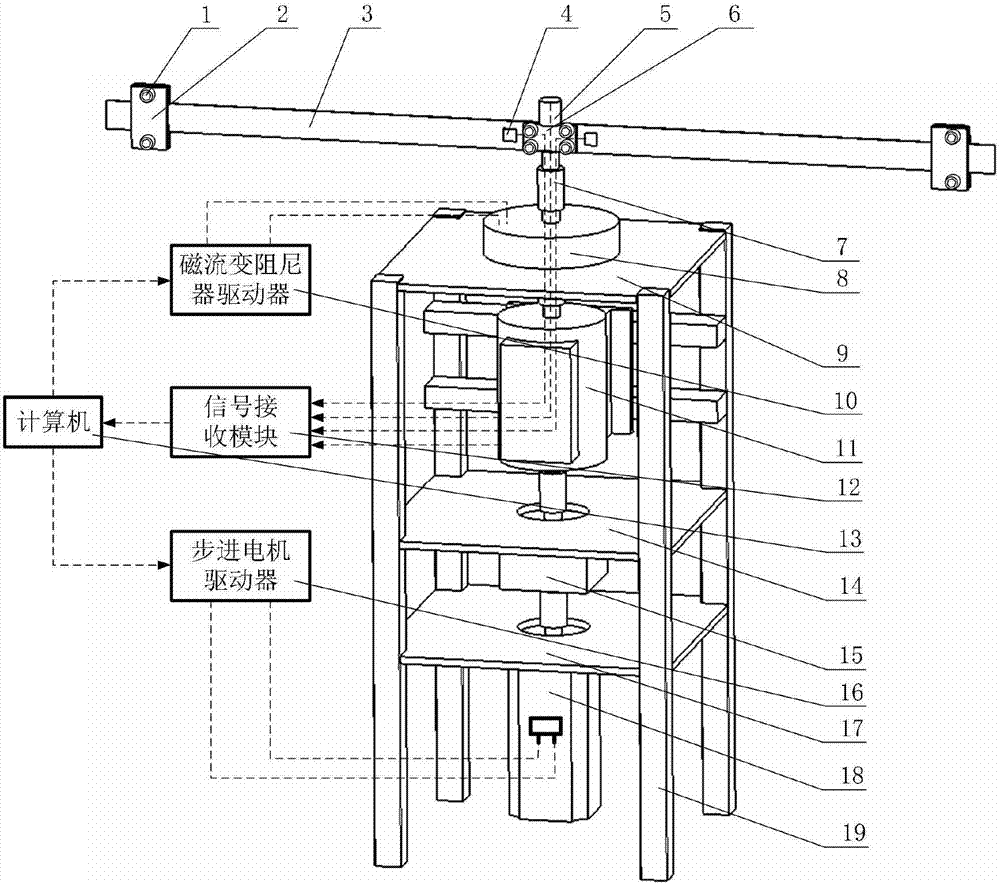

[0035] Such as figure 1 As shown, the vibration measurement device of the rotating flexible beam rigid-flexible coupling system includes the counterweight flexible collar part, the vibration and its interference signal detection part, the stepper motor drive control part and the magnetorheological damper vibration control part;

[0036] ——Counterweight flexible beam part:

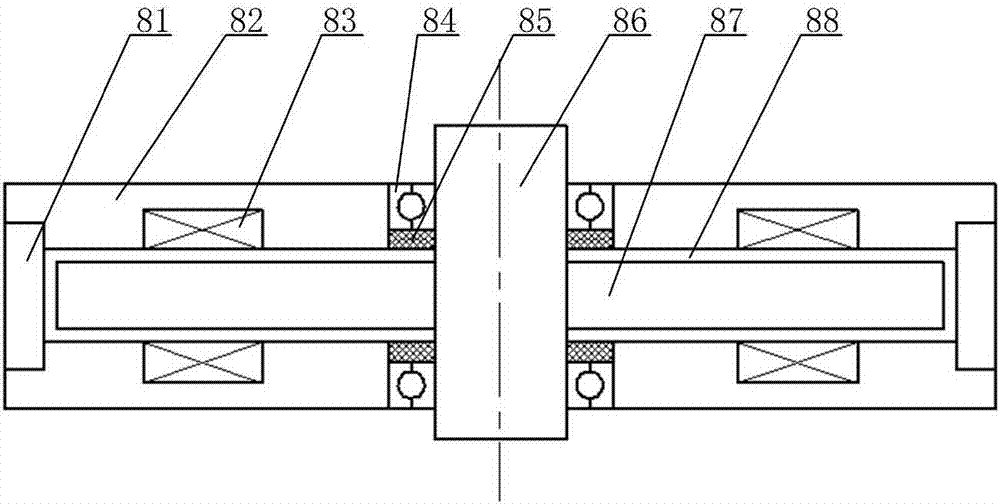

[0037] The counterweight flexible beam system consists of two flexible beams (3) with movable masses (2). One end of the flexible beams (3) fixes the mass (2), and the other end is connected to The rigid transmission shaft is connected by the output shaft of the harmonic reducer (15), the input and output shaft of the torque sensor (11), the input and output shaft of the magnetorheological damper (8), and the mechanical clamping device (6). The shaft is formed by a rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com