High-visibility waterproof leather production method

A manufacturing method and technology of visibility, applied in textiles and papermaking, etc., can solve the problems of inability to defoaming, decrease in visibility, and reduce visibility, and achieve the effect of improving appearance and use value, increasing added value, and excellent surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

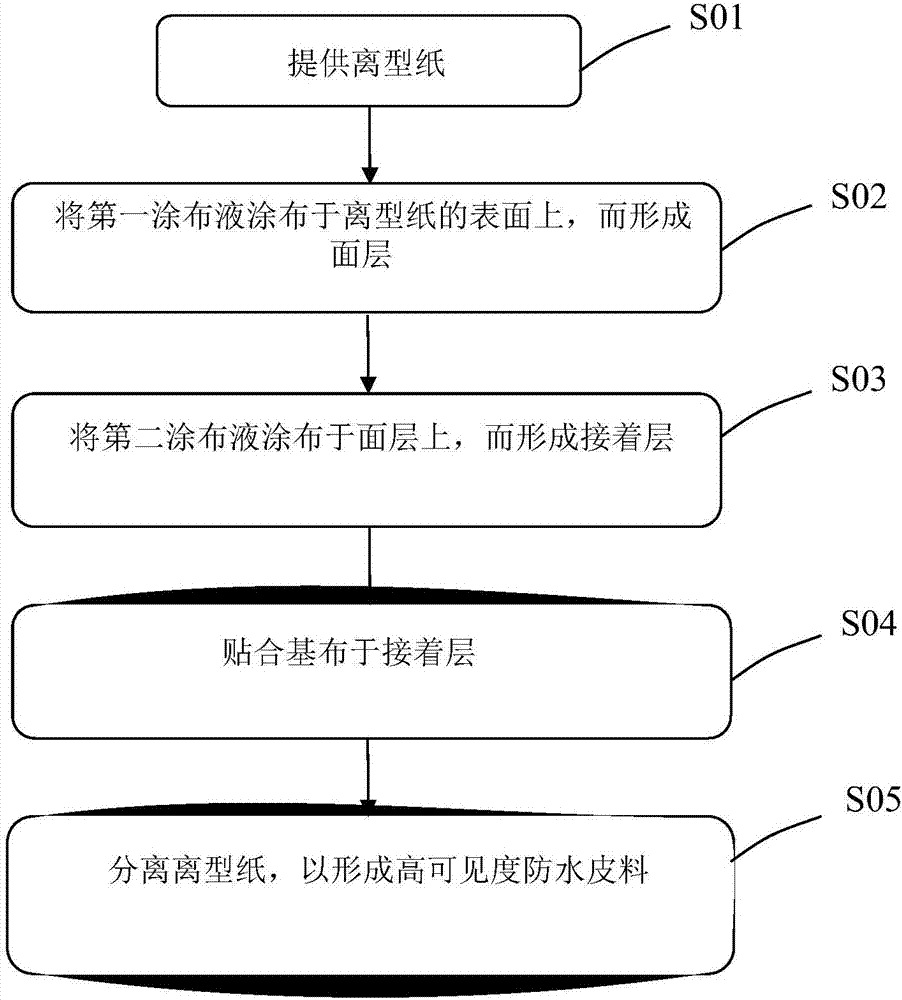

[0014] Please refer to figure 1 , a flow chart of the manufacturing method of the high-visibility waterproof leather material provided by the embodiment of the present invention; at the same time, please refer to Figure 2A-2E , is a cross-sectional structure diagram corresponding to each step in the manufacturing method of the high-visibility waterproof leather 10 provided by the embodiment of the present invention.

[0015] First, see step S01, such as Figure 2A As shown, a release paper 20 is provided, and the surface of the release paper 20 is smooth and matte. In detail, the characteristics of the release paper 20 are good flatness and low roughness, that is to say, the surface of the release paper 20 is usually a smooth surface, and a better coating thickness can be obtained when coating is performed. The distribution can also make the surface of the coating get a fairly good flatness.

[0016] See step S02, such as Figure 2B As shown, a coating machine is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com