Electrostatic chuck device

An electrostatic chuck and electrode layer technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc. The effect of improving the electric constant, avoiding technical barriers, and uniform electrostatic adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

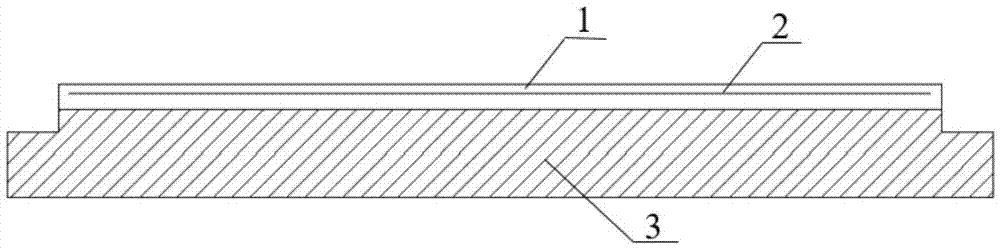

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

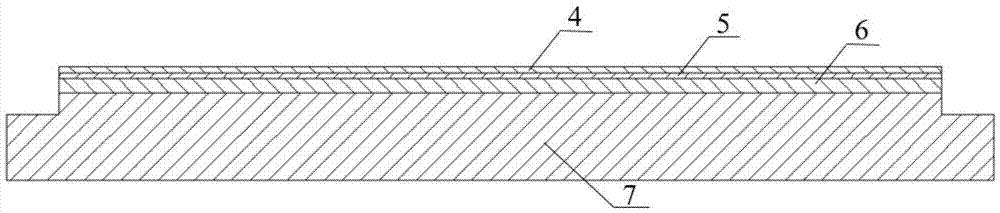

[0016] The invention provides an electrostatic chuck device, such as figure 2 As shown, it includes a first insulating layer 4, a second insulating layer 6, an electrode layer 5 and a metal layer 7, the first insulating layer 4 is arranged above the second insulating layer 6, and the electrode layer 5 is arranged on the first insulating layer 4 and the metal layer 7. Between the second insulating layers 6 , the second insulating layer 6 is disposed on the metal layer 7 , and the first insulating layer is made of sapphire material.

[0017] The inventors have discovered through research that the metal base is connected to an RF bias, and used as a cold sink or a heat source to control the temperature of the wafer. Generally, the insulating layer is usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com