Lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of electrochemical materials, can solve the problems of unusability and poor low-temperature performance of lithium-ion batteries, and achieve good solubility, good chemical stability, good electrochemical performance and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

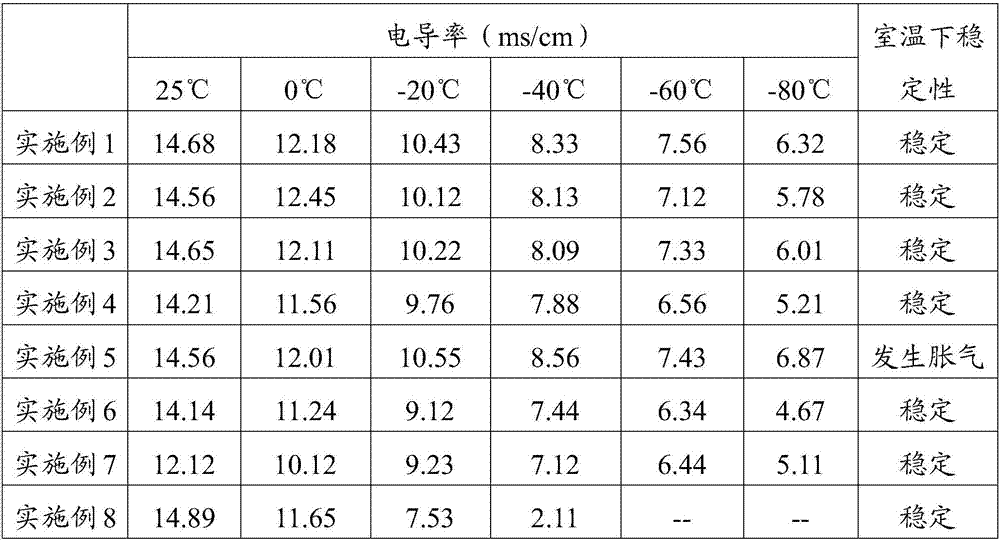

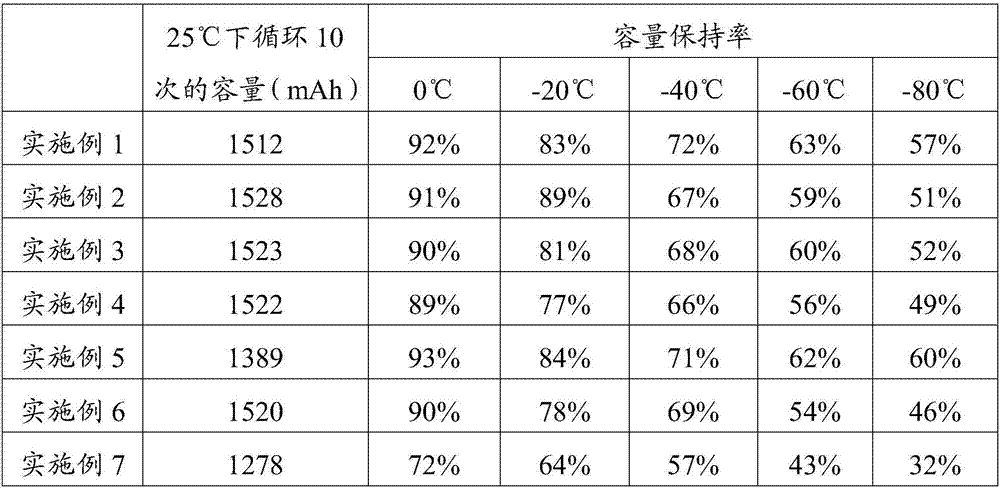

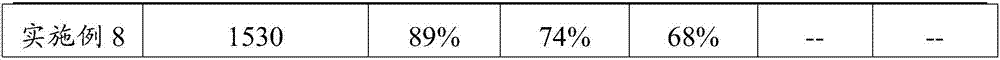

Examples

Embodiment 1

[0042] Ethylene carbonate, 2-butanone and dichloromethane are formulated into a ternary blend solvent in a mass ratio of 2:2:6; then LiPF is added to the above ternary blend solvent 6 Formulated as LiPF 6 Lithium-ion battery electrolyte with a concentration of 1mol / L.

[0043] The positive electrode current collector with the positive electrode active material attached thereto, the separator, and the negative electrode current collector with the negative electrode active material attached thereto are laminated, and then wound to obtain a cell. Among them, the positive electrode current collector is aluminum foil, and the positive electrode active material is composed of 90% LiCoO 2 , 5% carbon black and 5% binder, the thickness of the positive electrode current collector is 10 μm, and the thickness of the coating formed by the positive electrode active material is 80 μm; the negative electrode current collector is copper foil, and the negative electrode active material is com...

Embodiment 2

[0046]Ethylene carbonate, 2-butanone and dichloromethane are formulated into a ternary blend solvent in a mass ratio of 2:4:4; then LiBF is added to the above ternary blend solvent 4 formulated as LiBF 4 Lithium-ion battery electrolyte with a concentration of 1.2mol / L.

[0047] The positive electrode current collector with the positive electrode active material attached thereto, the separator, and the negative electrode current collector with the negative electrode active material attached thereto are laminated, and then wound to obtain a cell. Among them, the positive electrode current collector is aluminum foil, and the positive electrode active material is composed of 92% LiCoO 2 , 4% carbon black and 4% binder, the thickness of the positive electrode current collector is 30 μm, and the thickness of the coating formed by the positive electrode active material is 110 μm; the negative electrode current collector is copper foil, and the negative electrode active material is c...

Embodiment 3

[0050] Ethylene carbonate, 2-butanone and methylene chloride are formulated into a ternary blend solvent in a mass ratio of 2:1:7; then LiClO is added to the above ternary blend solvent 4 formulated as LiClO 4 Lithium-ion battery electrolyte with a concentration of 1.1mol / L.

[0051] The positive electrode current collector with the positive electrode active material attached thereto, the separator, and the negative electrode current collector with the negative electrode active material attached thereto are laminated, and then wound to obtain a cell. Among them, the positive electrode current collector is aluminum foil, and the positive electrode active material is composed of 92% LiCoO 2 , 4% carbon black and 4% binder, the thickness of the positive electrode current collector is 16 μm, and the thickness of the coating formed by the positive electrode active material is 96 μm; the negative electrode current collector is copper foil, and the negative electrode active material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com