A kind of catalytic ozonation water treatment method using titanium oxide as catalyst

A technology of ozonated water and treatment method, which is applied in oxidation water/sewage treatment, physical/chemical process catalyst, water/sewage treatment, etc., to achieve the effect of less loss of active components, inhibiting particle growth, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

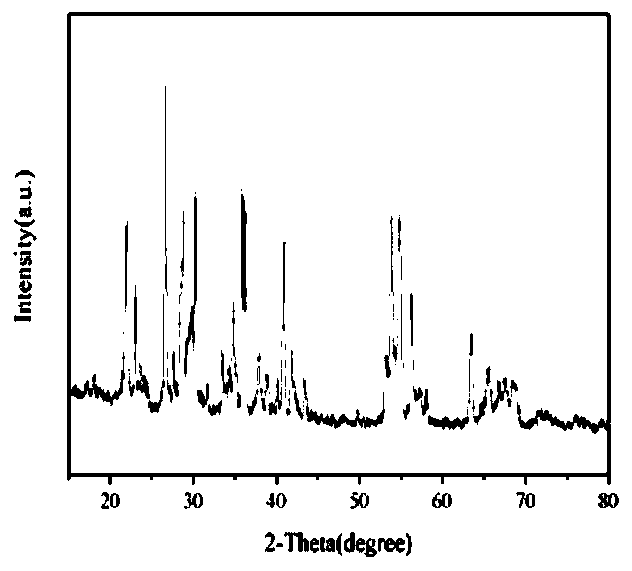

[0040] Weigh 15g of glucose and 35g of rutile titanium dioxide in a beaker, add water, mix and dry, put the obtained mixture into a tube furnace, set the reaction temperature to 1075°C under the condition of flowing nitrogen, and set the calcination time to 3h , Sample 1 was obtained after the reaction. Its XRD pattern is shown in figure 1 , indicating that all diffraction peaks can be related to Ti 6 o 11 The position of the peak matches, indicating that it is Ti 6 o 11 ; Its SEM picture is shown in Figure 4 , the nano-carbon fiber on the surface of the particle is a carbon layer coated on the surface; the BET specific surface area is 7.321m 2 / g.

Embodiment 2

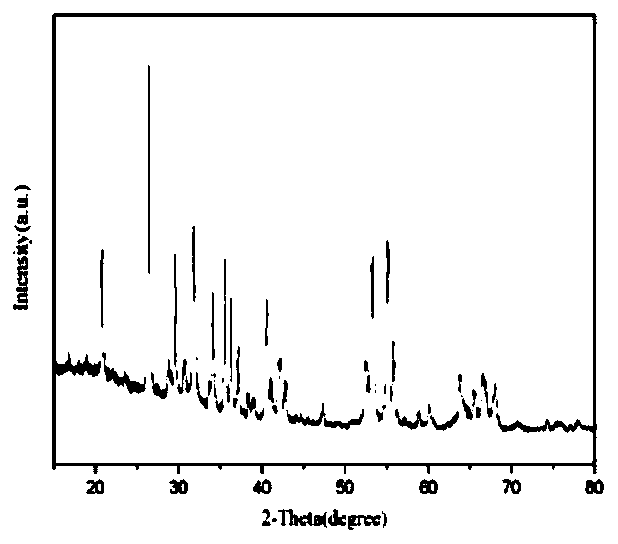

[0042]Weigh 20g of glucose and 30g of rutile titanium dioxide in a beaker, add water, mix, and dry, put the obtained mixture into a tube furnace, set the reaction temperature to 1050°C under the condition of flowing nitrogen, and the holding time to 1.5 h, sample 2 was obtained after the reaction was completed. Its XRD pattern is shown in figure 2 , indicating that all diffraction peaks can be related to Ti 4 o 7 The position of the peak matches, indicating that it is Ti 4 o 7 ; Its SEM picture is shown in Figure 5 , the nano-carbon fiber on the surface of the particle is a carbon layer coated on the surface; the BET specific surface area is 25.590m 2 / g.

Embodiment 3

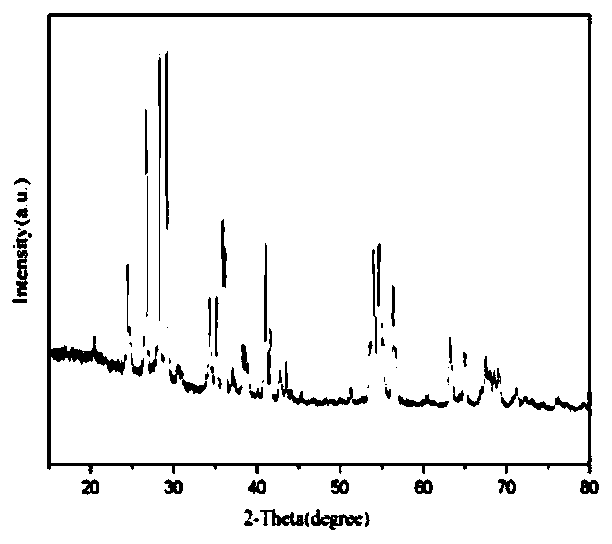

[0044] Weigh 5g of glucose and 45g of rutile titanium dioxide in a beaker, add water, mix, and dry, put the obtained mixture into a tube furnace, set the reaction temperature to 1000°C under the condition of flowing argon, and the calcination time is After 1h, sample 3 was obtained after the reaction was completed. Its XRD pattern is shown in image 3 , indicating that all diffraction peaks can be related to Ti 9 o 17 The position of the peak matches, indicating that it is Ti 9 o 17 ; Its SEM picture is shown in Figure 6 , the nano-carbon fiber on the surface of the particle is a carbon layer coated on the surface; the BET specific surface area is 8.657m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com