Hollow molybdenum disulfide/molybdenum trioxide flower-like spherical heterostructure nano material, preparation method and application

A molybdenum trioxide flower, molybdenum disulfide technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of affecting catalyst performance, weak cycle stability, low conductivity, etc. Easy batch preparation, excellent electrochemical performance, less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of hollow MoS 2 / MoO 3 A method for preparing a spherical heterostructure nanomaterial, comprising the steps of:

[0033] 1) In a 100mL beaker, add 22mg of ammonium tetrathiomolybdate and 22mg of urea, add 35ml of N,N-dimethylformamide, and sonicate in an ultrasonic cleaner for 50min to form a homogeneous solution. Then add 0.1ml hydrazine hydrate, and sonicate again for 30min in an ultrasonic cleaner;

[0034] 2) Transfer the solution obtained in step 1) into a 100ml reaction kettle, put it into an electric constant temperature blast drying oven for solvothermal reaction, keep at 200°C, and react for 10h;

[0035]3) After the reaction, cool down to room temperature naturally, centrifuge the reaction solution, wash the precipitate, and dry it in vacuum to obtain hollow MoS 2 / MoO 3 Flower spherical heterostructure nanomaterials.

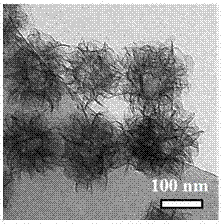

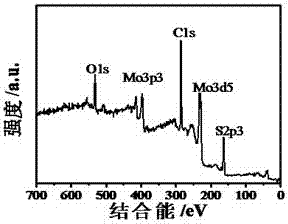

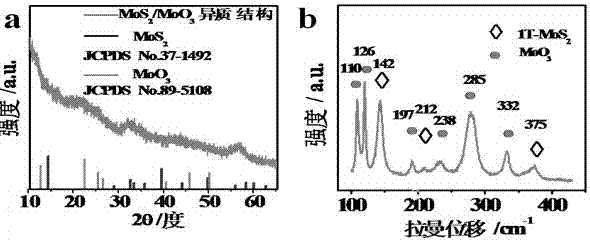

[0036] The resulting target product is hollow MoS 2 / MoO 3 The transmission electron microscope TEM image of flower spherical h...

Embodiment 2

[0048] A calcined MoS 2 / MoO 3 The preparation method of nanometer material, it comprises the steps:

[0049] 1) Add ammonium tetrathiomolybdate, urea, and hydrazine hydrate into DMF: same as Step 1 of Example 1);

[0050] 2) Solvothermal reaction: same as step 2 of Example 1);

[0051] 3) Washing, drying, and collecting the product are the same as Step 3) of Example 1.

[0052] 4) Carbonize at 350°C for 2h, cool naturally to room temperature, and the obtained black powder is calcined MoS 2 / MoO 3 nanomaterials.

Embodiment 3-6

[0054] A kind of hollow MoS 2 / MoO 3 A method for preparing a spherical heterostructure nanomaterial, comprising the steps of:

[0055] 1) Add ammonium tetrathiomolybdate, urea, and hydrazine hydrate into DMF: same as Step 1 of Example 1);

[0056] 2) Solvothermal reaction, the difference is that the reaction time is 2, 4, 6, 8h respectively: other steps are the same as step 2 of Example 1);

[0057] Washing, drying, and collecting the product are the same as Step 3 of Example 1).

[0058] Examples 3 to 6 prepare the obtained hollow MoS 2 / MoO 3 Transmission electron microscope TEM image of flower spherical heterostructure nanomaterials Figure 7 shown. In the first stage, within 2 h, solid MoS was grown 2 / MoO 3 Ball flowers, the product does not have a cavity structure ( Figure 7 Middle a). With the increase of reaction time, after 6 h of reaction, the bulb flower gradually formed a cavity structure, and the cavity structure gradually became larger in the subseque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com