Preparation method of fresh food insulation environment-friendly express packing bag

A packaging bag and food technology, which is applied in the field of fresh food express insulation structure and disposable fully degradable packaging bags, which can solve the problems of unsatisfactory insulation effect and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is described in further detail.

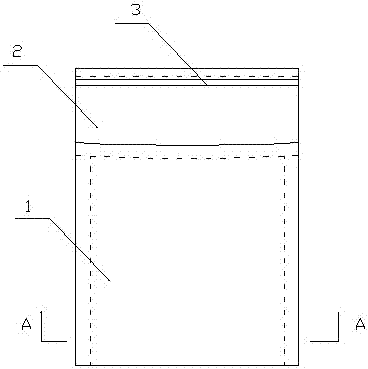

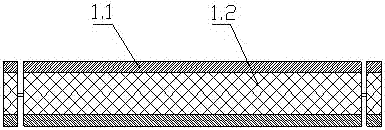

[0031] see figure 1 , 2, the present invention relates to a kind of preparation method of fresh food thermal insulation and environmental protection express packaging bag, described packaging bag comprises the bag body 1 that is used for accommodating articles, and one side of described bag body 1 has bag opening, and in A flange 2 that can close the mouth of the bag is formed at the mouth of the bag, and an adhesive tape 3 is pasted on the flange 2. The two sides of the bag body 1 are sewn by ultrasonic waves. The bag body 1 is made of a protective film 1.1 and a non-woven fabric. The cloth core material 1.2 is composed of the non-woven fabric core material 1.2 wrapped in the protective film 1.1, the protective film 1.1 at the mouth of the bag is sealed by a hot-melt sealing machine, the protective film 1.1 on both sides of the bag body 1 and the non-woven fabric core material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com