Three-section combined ultrafiltration hydrogen-enriched water purification rod

A three-stage, hydrogen filtration technology, applied in multi-stage water treatment, filtration treatment, water/sewage treatment, etc., can solve the problems of emphasizing use cost and service life, large volume and structure, complicated device, etc., and achieves low design cost. , Small volume and structure to ensure the effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

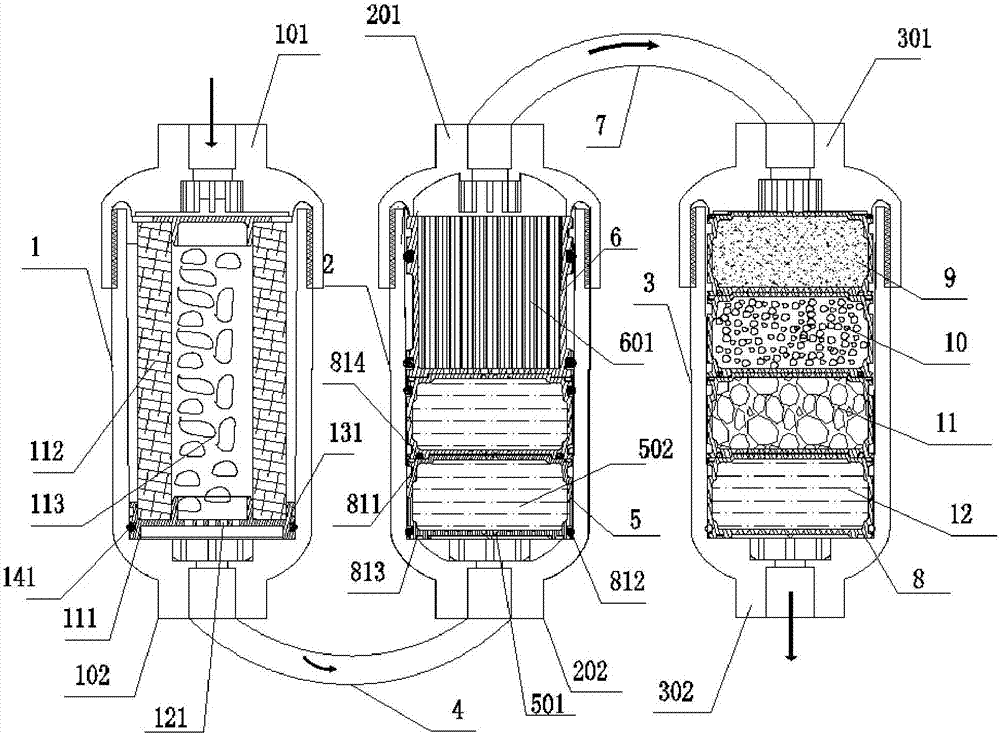

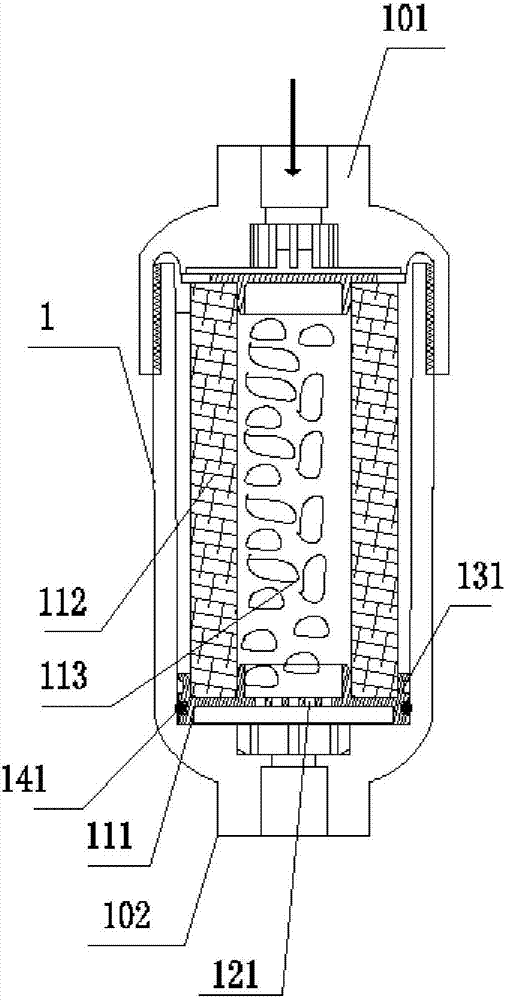

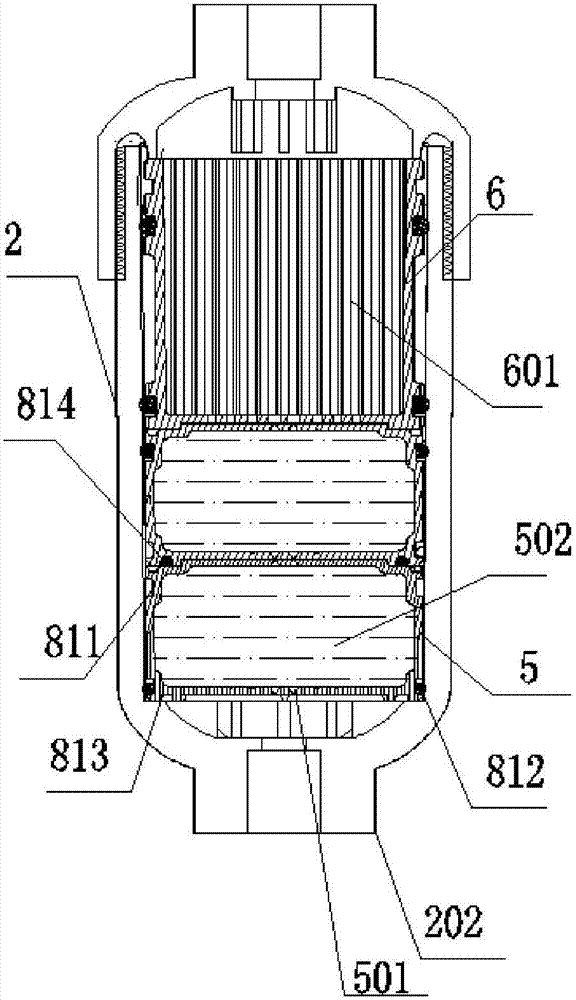

[0071] refer to figure 1 , figure 2 , image 3 and Figure 4 A three-stage combined ultrafiltration hydrogen water stick shown includes a first stick body 1, a second stick body 2 and a third stick body 3, and the top of the first stick body 1 is provided with a first water inlet port 101, the bottom of the first rod 1 is provided with a first water outlet 102, the top of the second rod 2 is provided with a second water outlet 201, and the bottom of the second rod 2 is provided with a second inlet Water end 202, the top of the third rod 3 is provided with a third water inlet 301, the bottom of the third rod 3 is provided with a third water outlet 302, which is set inside the first rod 1 There are upper and lower end caps 111, and PP cotton 112 is fitted between the two end caps 111. Granular carbon 113 is arranged at the inner ring position of the PP cotton 112, and the end cap below is arranged The surface of 111 is evenly distributed with first water holes 121, a pipe f...

Embodiment 2

[0079] refer to figure 1 , figure 2 , image 3 and Figure 4 A three-stage combined ultrafiltration hydrogen water stick shown includes a first stick body 1, a second stick body 2 and a third stick body 3, and the top of the first stick body 1 is provided with a first water inlet port 101, the bottom of the first rod 1 is provided with a first water outlet 102, the top of the second rod 2 is provided with a second water outlet 201, and the bottom of the second rod 2 is provided with a second inlet The water end 202, the top of the third rod 3 is provided with a third water inlet 301, the bottom of the third rod 3 is provided with a third water outlet 302, which is set inside the first rod 1 There are upper and lower end caps 111, and PP cotton 112 is fitted between the two end caps 111. Granular carbon 113 is arranged at the inner ring position of the PP cotton 112, and the end cap below is arranged The surface of 111 is evenly distributed with first water holes 121, a pi...

Embodiment 3

[0088] refer to figure 1 , figure 2 , image 3 and Figure 4 A three-stage combined ultrafiltration hydrogen water stick shown includes a first stick body 1, a second stick body 2 and a third stick body 3, and the top of the first stick body 1 is provided with a first water inlet port 101, the bottom of the first rod 1 is provided with a first water outlet 102, the top of the second rod 2 is provided with a second water outlet 201, and the bottom of the second rod 2 is provided with a second inlet Water end 202, the top of the third rod 3 is provided with a third water inlet 301, the bottom of the third rod 3 is provided with a third water outlet 302, which is set inside the first rod 1 There are upper and lower end caps 111, and PP cotton 112 is fitted between the two end caps 111. Granular carbon 113 is arranged at the inner ring position of the PP cotton 112, and the end cap below is arranged The surface of 111 is evenly distributed with first water holes 121, a pipe f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com