A kind of epoxidized polyester resin, its preparation method and powder coating composition containing it

A technology for epoxidizing polyester and polyester resin, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of less epoxy, high formula cost, and corrosion cost of metal substrates, and achieve leveling Good water resistance, excellent boiling performance and weather resistance, high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

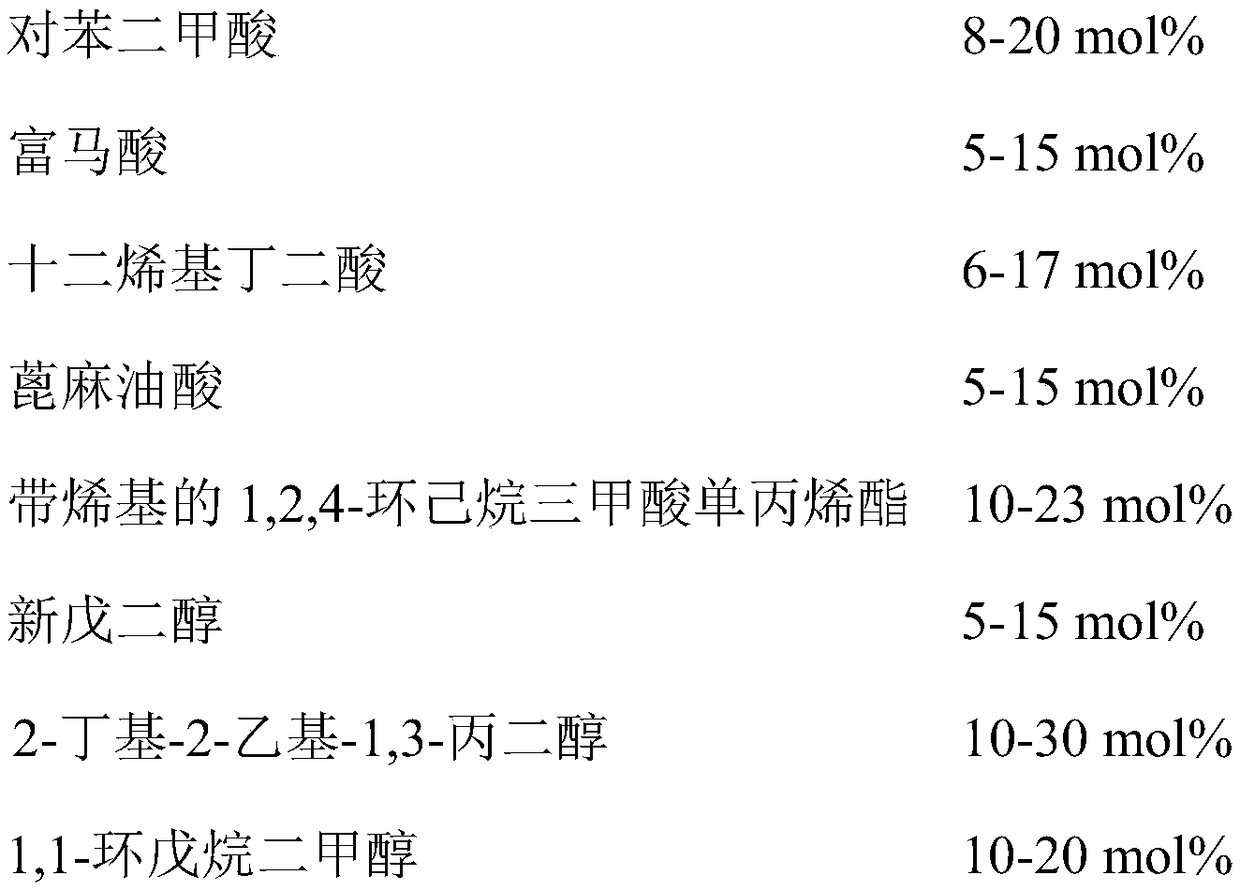

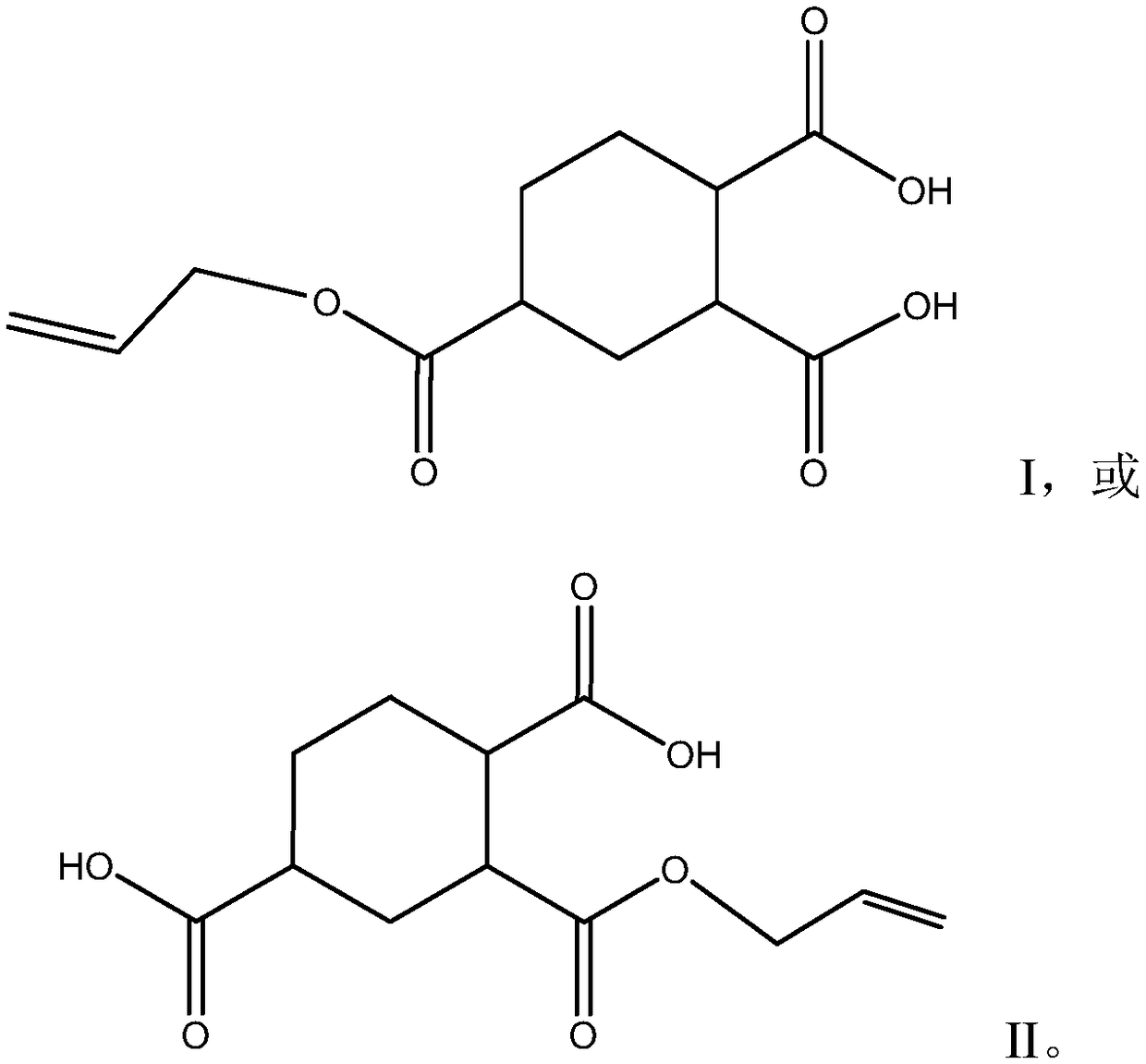

[0080] A kind of epoxidized polyester resin, the main raw material and molar proportion of preparing hydroxyl-terminated polyester resin are:

[0081] 8 mol of terephthalic acid, 10 mol of fumaric acid, 9 mol of dodecenyl succinic acid, 12 mol of ricinoleic acid, 10 mol of 1,2,4-cyclohexanetricarboxylate monopropenyl with alkenyl, 8 mol of neopentyl glycol , 2-butyl-2-ethyl-1,3-propanediol 25mol, 1,1-cyclopentanedimethanol 15mol, 4-pentenol 3mol;

[0082] The reaction catalyst is samarium oxide, and the consumption is 0.1mol;

[0083] The polymerization inhibitor is hydroquinone, and the consumption is 0.02mol;

[0084] Then, the obtained hydroxyl-terminated polyester resin is prepared in the following ratio to obtain epoxidized polyester resin:

[0085] Hydroxyl-terminated polyester 35mol

[0086] Hydrogen peroxide 65mol

[0087] The epoxidation reaction catalyst is phosphotungstic acid, and the dosage is 0.5mol.

[0088] The preparation method of epoxidized polyester re...

Embodiment 2

[0094] Same as Example 1, except for the following differences:

[0095] The main raw materials and molar proportions for preparing hydroxyl-terminated polyester resin are:

[0096] 20 mol of terephthalic acid, 5 mol of fumaric acid, 6 mol of dodecenylsuccinic acid, 5 mol of ricinoleic acid, 23 mol of 1,2,4-cyclohexanetricarboxylate monopropenyl with alkenyl, 5 mol of neopentyl glycol , 2-butyl-2-ethyl-1,3-propanediol 20mol, 1,1-cyclopentanedimethanol 10mol, 4-pentenol 6mol;

[0097] The reaction catalyst is samarium oxide, and the consumption is 0.1mol;

[0098] The polymerization inhibitor is hydroquinone, and the consumption is 0.02mol;

[0099] Then, the obtained hydroxyl-terminated polyester resin is prepared in the following ratio to obtain epoxidized polyester resin:

[0100] Hydroxy terminated polyester 20mol

[0101] Hydrogen peroxide 80mol

[0102] The epoxidation reaction catalyst is phosphotungstic acid, and the dosage is 0.5 mol.

Embodiment 3

[0104] Same as Example 1, except for the following differences:

[0105] The main raw materials and molar proportions for preparing hydroxyl-terminated polyester resin are:

[0106] 10 mol of terephthalic acid, 10 mol of fumaric acid, 10 mol of dodecenyl succinic acid, 5 mol of ricinoleic acid, 10 mol of 1,2,4-cyclohexanetricarboxylate monopropenyl with alkenyl, 10 mol of neopentyl glycol , 2-butyl-2-ethyl-1,3-propanediol 30mol, 1,1-cyclopentanedimethanol 10mol, 4-pentenol 5mol;

[0107] The reaction catalyst is samarium oxide, and the consumption is 0.1mol;

[0108] The polymerization inhibitor is hydroquinone, and the consumption is 0.02mol;

[0109] Then, the obtained hydroxyl-terminated polyester resin is prepared in the following ratio to obtain epoxidized polyester resin:

[0110] Hydroxy terminated polyester 70mol

[0111] Hydrogen peroxide 30mol

[0112] The epoxidation reaction catalyst is phosphotungstic acid, and the dosage is 0.5 mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com