High-wear resistance inkjet ink composition and preparation method thereof

A technology of inkjet ink and composition, applied in the field of ink composition, water-based inkjet ink composition, and the preparation field of said inkjet ink composition, can solve the problems such as large particle size and limited application of water-based fluorocarbon coatings, Achieve high weather resistance, good printing stability and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

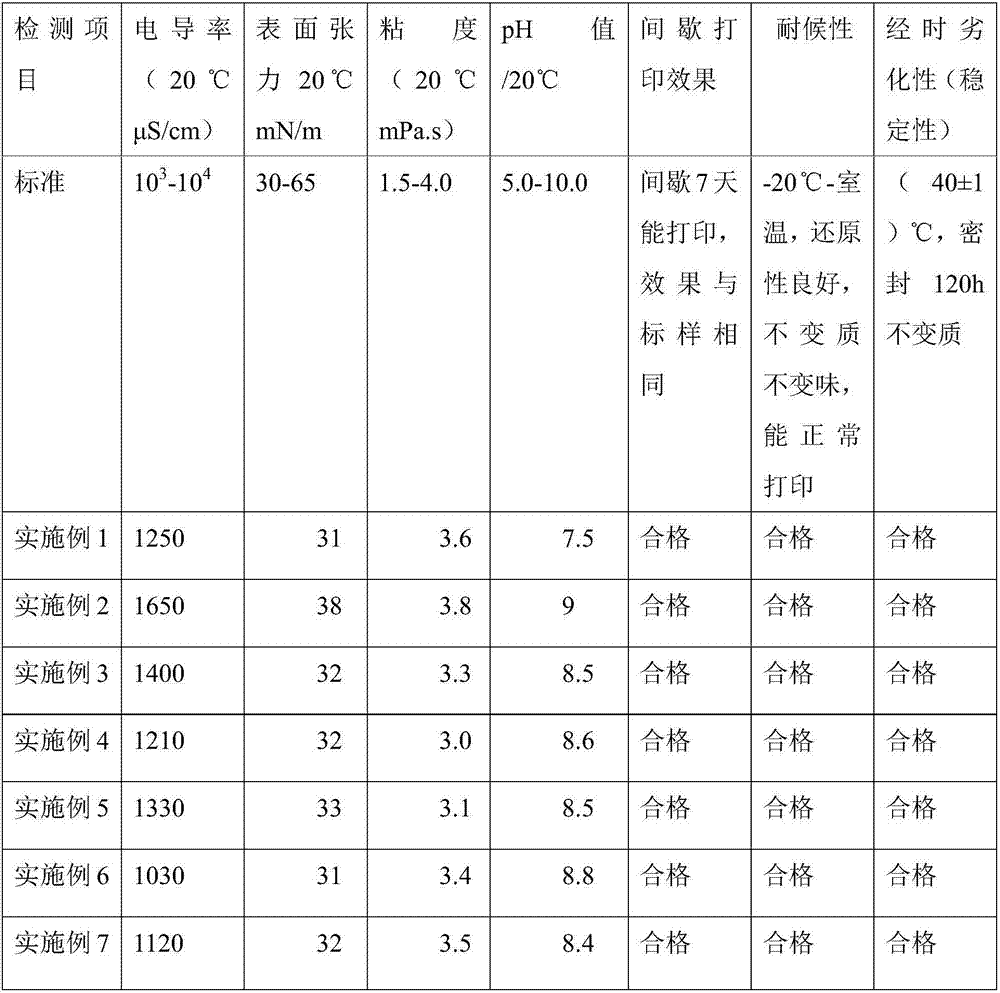

Examples

Embodiment 1

[0028] A highly weather-resistant inkjet ink composition, based on weight percentage, prepared from the following components: rutile titanium dioxide: 20%, SN-5040 dispersant: 10%, LR-9610: 30%, propylene three Alcohol: 5%, propylene glycol: 2%, Capstone FS-61: 1.5%, sodium hydroxide: 0.01%, citric acid: 0.1%, triethanolamine: 0.1%, 5-chloro-2-methyl-4-isothiazole Lin-3-one: 0.05%, deionized water: the balance. The preparation steps of the inkjet ink composition include:

[0029] 1) The weight of rutile titanium dioxide, SN-5040 dispersant, glycerol, Capstone FS-61, triethanolamine, 5-chloro-2-methyl-4-isothiazolin-3-one, and the After mixing the ionized water, grind it with a nano sand mill until the particle size of the mixture is D90≤200nm;

[0030] 2) Add LR-9610 of the above weight to the ground mixture of step 1), stir and mix well at a speed of 300 rad / min, and filter with a filter with a filtration accuracy of 0.22 μm to obtain the spray Ink ink composition.

Embodiment 2

[0032] A highly weatherable inkjet ink composition, calculated by weight percentage, which is prepared from the following components: C.I. Pigment Black 7:1%, DF1213 dispersant: 0.2%, HD-8327: 15%, glycerol: 15%, propylene glycol methyl ether: 15%, PF151N: 0.01%, lactic acid: 0.5%, triethanolamine: 1%, 5-chloro-2-methyl-4-isothiazolin-3-one: 0.05%, deionized water: the balance. The preparation process of the inkjet ink composition is similar to that of Example 1.

Embodiment 3

[0034] A highly weatherable inkjet ink composition, based on weight percentage, prepared from the following components: Pigment Blue 28: 5%, SN-5040 dispersant: 3%, HD-8327: 20%, ethanol: 10%, 1,2-hexanediol: 10%, Capstone FS-61: 1%, citric acid: 1%, lactic acid: 0.2%, 5-chloro-2-methyl-4-isothiazoline-3- Ketone: 0.05%, deionized water: the balance. The preparation process of the inkjet ink composition is similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com