MES system used for engine chain wheel chamber shell assembling detection

A technology of assembly inspection and sprocket room, applied in the field of MES system, can solve problems such as easy flow of workpieces, workpiece skipping, lack of production data function modules, etc., so as to improve packing efficiency, reduce product error rate, and improve production accuracy. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

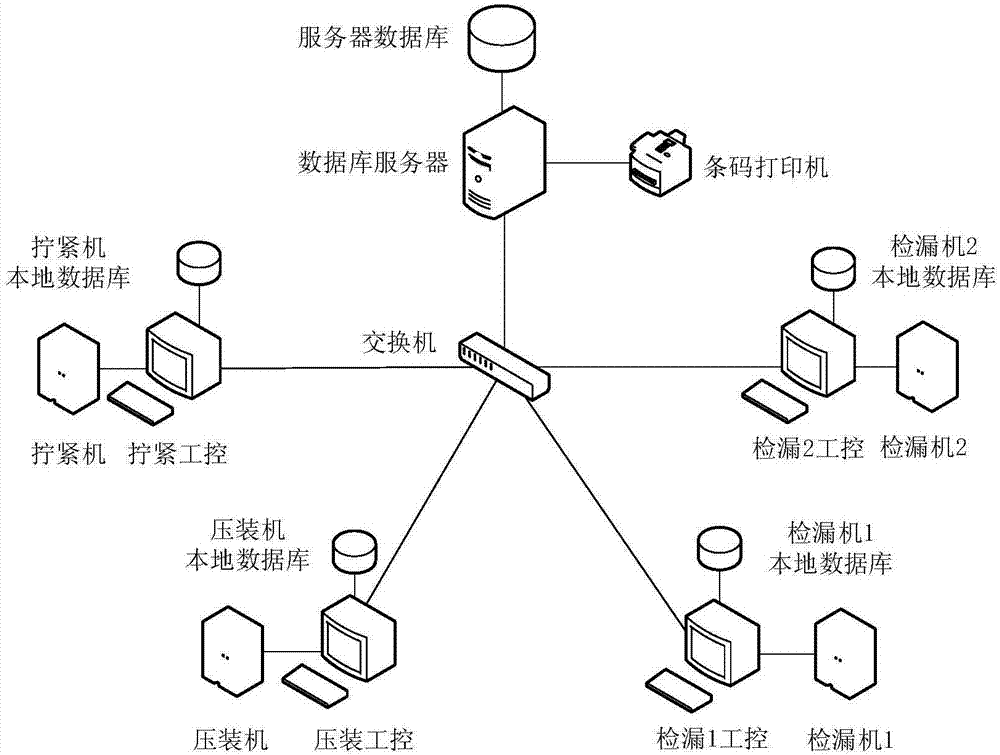

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

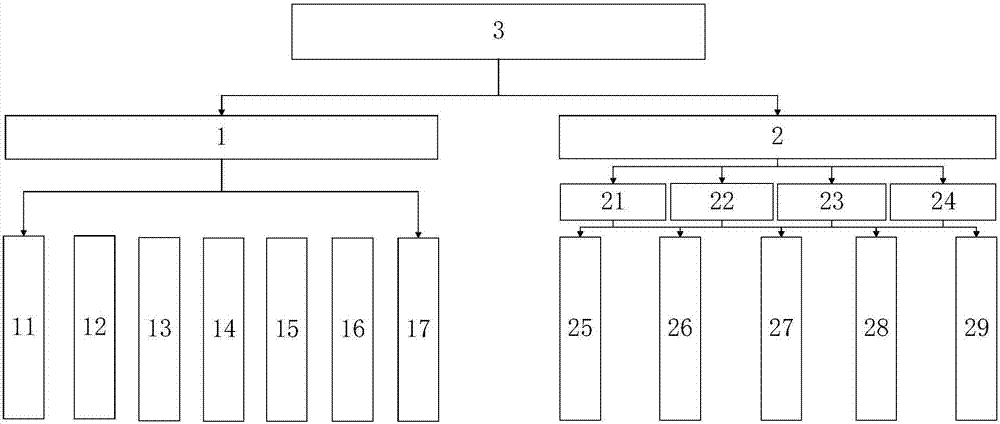

[0023] An MES system 3 for assembly detection of engine sprocket housing housing, used for assembly detection of engine sprocket housing housing wherein, the sprocket housing assembly detection process includes the following four stages:

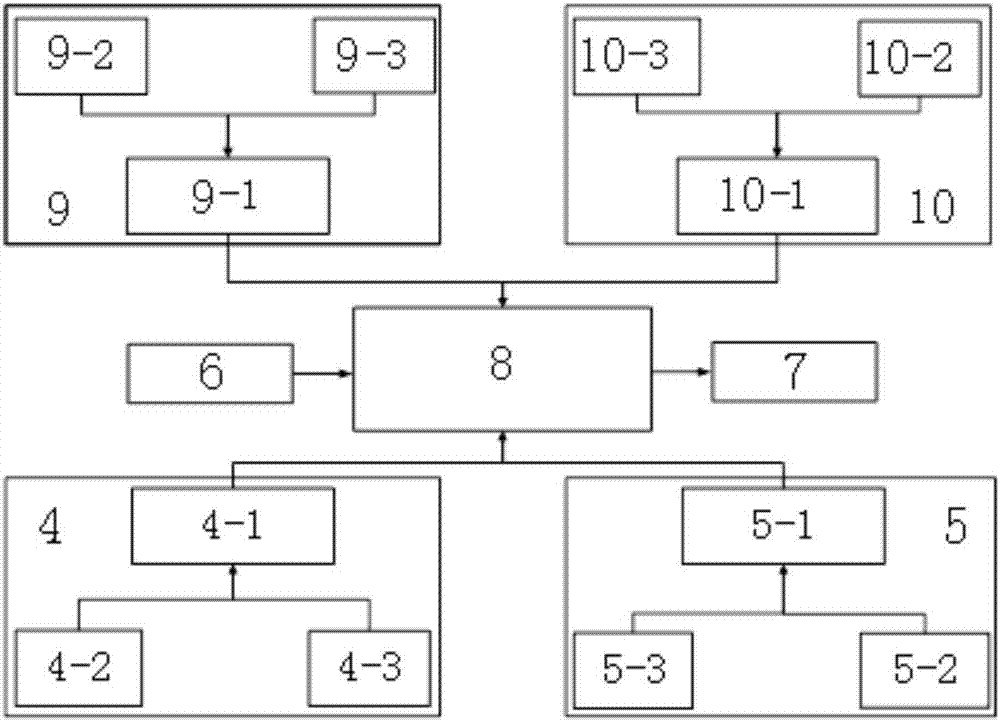

[0024] In the first stage, bolts are tightened on the sprocket housing;

[0025] In the second stage, press-fit the sprocket housing, which further includes the following steps: press-fit the straight tube first, and then press-fit the bent tube;

[0026] In the third stage, the first leak detection operation is performed on the cavity of the sprocket housing;

[0027] In the fourth stage, the second leak detection operation is perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com