Preparation method of air cathode of magnesium seawater battery

A technology of air cathode and seawater battery, applied in battery electrodes, electrical components, immersion batteries, etc., can solve the problems of air cathode discharge current density to be improved, high failure rate of air cathode, and high requirements of film making process, so as to achieve guaranteed performance , Improve electrode efficiency, reduce the effect of film making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

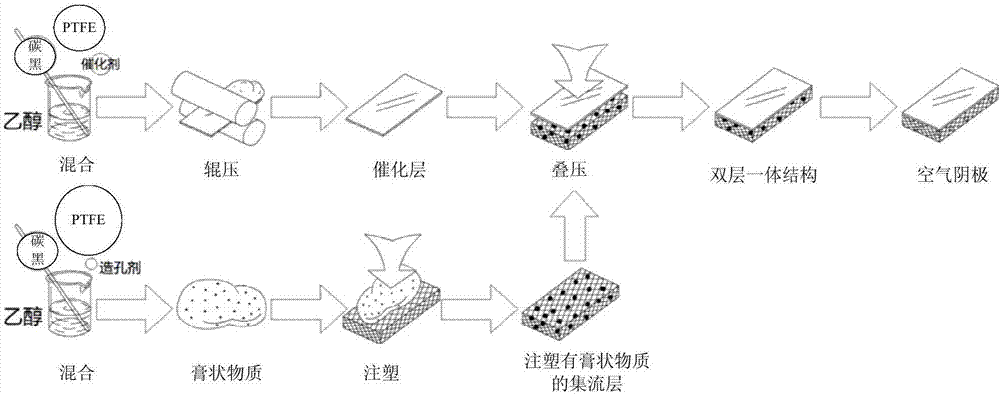

[0033] The preparation method of the air cathode of a kind of magnesium seawater battery that this embodiment proposes, its process schematic diagram is as follows figure 1 As shown, it includes the following steps:

[0034] ① Take the prepared catalytic layer, and take the nickel foam with a thickness of 1.5 mm as the current collector layer.

[0035] Here, the preparation process of the catalytic layer is: the mass percentage is 40% carbon black, the mass percentage is 20% catalyst (as the mixture of manganese dioxide and carbon black, the mixture of silver and carbon black) and the mass percentage is 40% The concentration of 60% polytetrafluoroethylene (PTFE) emulsion is placed in ethanol as a dispersant, and stirred for a long time to a paste; then remove the ethanol to obtain a paste; then roll the paste through a film rolling machine A film having a thickness of 0.3 mm was formed, which served as a catalyst layer.

[0036]2. prepare the pasty substance that diffuses: g...

Embodiment 2

[0044] The preparation method of the air cathode of a kind of magnesium seawater battery that this embodiment proposes, its process schematic diagram is as follows figure 1 As shown, it includes the following steps:

[0045] ① Take the prepared catalytic layer, and take the nickel foam with a thickness of 2 mm as the current collector layer.

[0046] Here, the preparation process of the catalytic layer is: the mass percentage is 45% carbon black, the mass percentage is 20% catalyst (as the mixture of manganese dioxide and carbon black, the mixture of silver and carbon black) and the mass percentage is 35% % concentration is that 60% polytetrafluoroethylene emulsion is placed in the ethanol as dispersant, and is stirred to paste for a long time; Then remove ethanol to obtain pasty substance; Roll pasty substance by rolling film machine to form thickness again 0.3 mm membrane, which acts as a catalytic layer.

[0047] 2. prepare the pasty material that diffuses: get the carbon...

Embodiment 3

[0055] The preparation method of the air cathode of a kind of magnesium seawater battery that this embodiment proposes, its process schematic diagram is as follows figure 1 As shown, it includes the following steps:

[0056] ① Take the prepared catalytic layer, and take nickel foam with a thickness of 1 mm as the current collector layer.

[0057] Here, the preparation process of catalytic layer is: the carbon black that mass percentage is 35%, the catalyst (such as the mixture of manganese dioxide and carbon black, the mixture of silver and carbon black) that mass percentage is 25% and mass percentage are 40% The polytetrafluoroethylene emulsion with a concentration of 60% is placed in ethanol as a dispersant, and stirred for a long time until it becomes a paste; mm membrane, which acts as a catalytic layer.

[0058] 2. prepare the pasty material that diffuses: get the carbon black that mass percentage is 38%, the polytetrafluoroethylene emulsion that the concentration of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com