Method for extracting tannin, polysaccharides and chestnut shell pigments from chestnut shells

A technology of chestnut shell pigment and chestnut shell, which is applied in the field of extracting tannin, polysaccharide and chestnut shell pigment, can solve the problems of excessive heavy metals in the extract, low extraction efficiency and high cost, and achieves good product color, high extraction efficiency, stay active

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

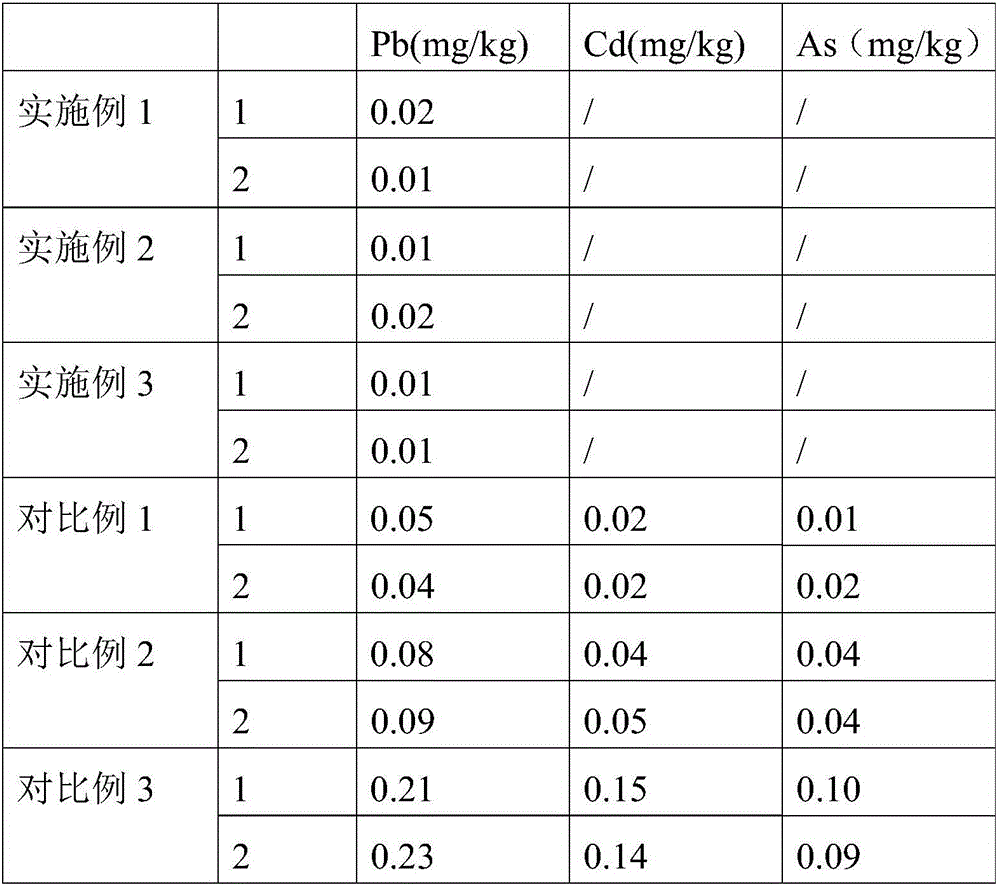

Examples

Embodiment 1

[0040] Tannins, polysaccharides and chestnut shell pigments were extracted from chestnut shells as follows:

[0041] 1. Material selection: select fresh chestnut shells peeled off by a peeling machine without mold, and remove moldy materials.

[0042] 2. Drying: After the raw materials are selected, dry the chestnut shells with 95°C hot air, and then store them properly.

[0043] 3. Extraction: Put 10 kg of chestnut shells crushed to 80 mesh into an extraction tank, add 80 L of sodium hydroxide solution with a pH value of 12.8, extract for 2 hours, and filter to obtain the first extraction solution. According to the ratio of mass volume ratio 1:8, the filtered chestnut shell filter residue and the sodium hydroxide solution with a pH value of 12.8 are put into the extraction tank, leached for 2 hours, filtered to obtain the second leaching solution, and combined twice Extraction solution.

[0044] 4. Coarse filtration: the extract is filtered with a 300-mesh bag filter to rem...

Embodiment 2

[0051] With reference to the method described in Example 1, tannins, polysaccharides and chestnut shell pigments are extracted, the difference is only that the extraction is carried out in the following manner:

[0052] Put 10 kg of chestnut shells crushed to 80 mesh into an extraction tank, add 100 L of sodium hydroxide solution with a pH value of 13.2, extract for 2 hours, and filter to obtain the first extract. According to the ratio of mass volume ratio 1:10, put the filtered chestnut shell filter residue and the sodium hydroxide solution with a pH value of 13.2 into the extraction tank, leaching for 2 hours, and filtering to obtain the second extraction solution, which was combined twice Extraction solution.

Embodiment 3

[0054] With reference to the method described in Example 1, tannins, polysaccharides and chestnut shell pigments are extracted, the difference is only that the extraction is carried out in the following manner:

[0055] Put 10 kg of chestnut shells crushed to 80 mesh into an extraction tank, add 120 L of sodium hydroxide solution with a pH value of 13.5, extract for 2 hours, and filter to obtain the first extract. According to the ratio of mass volume ratio of 1:12, put the filtered chestnut shell filter residue and the sodium hydroxide solution with a pH value of 13.5 into the extraction tank, extract for 2 hours, and filter to obtain the second extraction solution, which is combined twice Extraction solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com