Anti-corrosion sewage pipeline material and preparation method thereof

A sewage pipeline and anti-corrosion technology, applied in the field of pipeline materials, can solve the problems of wasting manpower and material resources, shortening pipeline life, not environmental protection, etc., and achieve the effects of preventing corrosion, high elongation at break, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

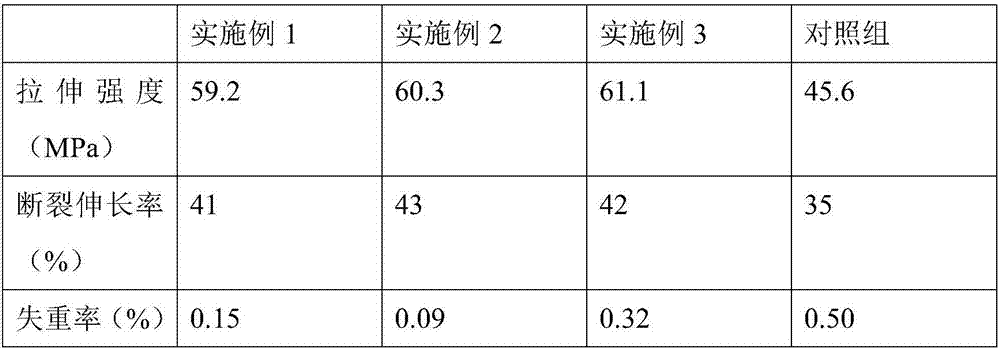

Examples

Embodiment 1

[0020] An anti-corrosion sewage pipe material, comprising the following raw materials in parts by weight: 10 parts of polybutene, 20 parts of polypropylene, 3 parts of unsaturated polyester resin, 3 parts of brucite, 2 parts of liquid nitrile rubber, lignin 1 part of calcium sulfonate, 1 part of dipentaerythritol diphosphite, 2 parts of fatty alcohol polyoxyethylene ether, 5 parts of diisodecyl phthalate, 3 parts of nonionic surfactant, 2 parts of plasticizer, anti-corrosion 2 doses.

[0021] The preservative is selected from one of potassium sorbate, sodium benzoate, xylene or methylparaben or a mixture thereof.

[0022] The unsaturated polyester resin is p-phenylene type unsaturated polyester resin.

[0023] The nonionic surfactant is selected from polyoxyalkylene alkyl ether type, polyoxyalkylene styrenated phenyl ether type, polyoxyalkylene alkylphenyl ether type, polyoxyalkylene Alkylamine type, polyoxyalkylene amine type, polyoxyalkylene alkylamide type, polyoxyalkylen...

Embodiment 2

[0032] An anti-corrosion sewage pipe material, comprising the following raw materials in parts by weight: 20 parts of polybutene, 30 parts of polypropylene, 7 parts of unsaturated polyester resin, 5 parts of brucite, 3 parts of liquid nitrile rubber, lignin 4 parts of calcium sulfonate, 1 part of dipentaerythritol diphosphite, 10 parts of fatty alcohol polyoxyethylene ether, 10 parts of diisodecyl phthalate, 6 parts of nonionic surfactant, 3 parts of plasticizer, anti-corrosion 6 doses.

[0033] The preservative is selected from one of potassium sorbate, sodium benzoate, xylene or methylparaben or a mixture thereof.

[0034] The unsaturated polyester resin is p-phenylene type unsaturated polyester resin.

[0035] The nonionic surfactant is selected from polyoxyalkylene alkyl ether type, polyoxyalkylene styrenated phenyl ether type, polyoxyalkylene alkylphenyl ether type, polyoxyalkylene Alkylamine type, polyoxyalkylene amine type, polyoxyalkylene alkylamide type, polyoxyalky...

Embodiment 3

[0044] An anti-corrosion sewage pipe material, comprising the following raw materials in parts by weight: 30 parts of polybutene, 40 parts of polypropylene, 10 parts of unsaturated polyester resin, 7 parts of brucite, 4 parts of liquid nitrile rubber, lignin 5 parts of calcium sulfonate, 2 parts of dipentaerythritol diphosphite, 15 parts of fatty alcohol polyoxyethylene ether, 15 parts of diisodecyl phthalate, 9 parts of nonionic surfactant, 4 parts of plasticizer, anti-corrosion 10 doses.

[0045] The preservative is selected from one of potassium sorbate, sodium benzoate, xylene or methylparaben or a mixture thereof.

[0046] The unsaturated polyester resin is p-phenylene type unsaturated polyester resin.

[0047] The nonionic surfactant is selected from polyoxyalkylene alkyl ether type, polyoxyalkylene styrenated phenyl ether type, polyoxyalkylene alkylphenyl ether type, polyoxyalkylene Alkylamine type, polyoxyalkylene amine type, polyoxyalkylene alkylamide type, polyoxya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com