Foamable polyolefin and polystyrene blend particles and preparation method thereof

A polystyrene and styrene polymer technology, applied in the field of foam materials, can solve the problems of poor product performance and low graft rate, and achieve the effects of excellent product performance, excellent toughness and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

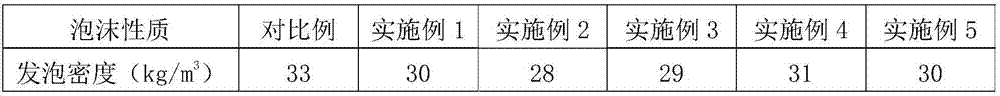

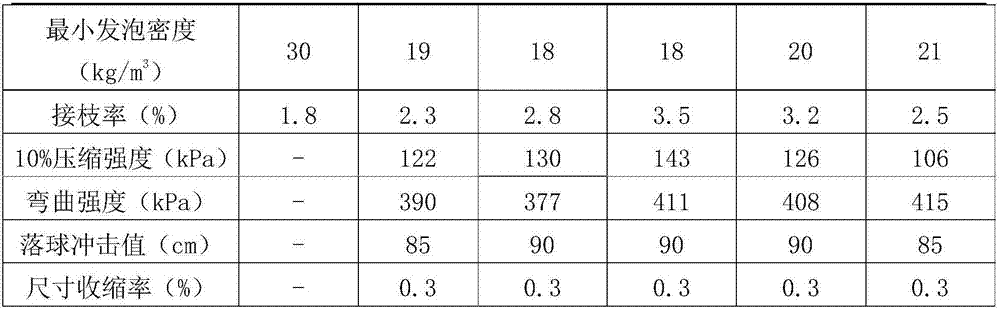

[0032] Weigh 80 parts by weight of PS, 10 parts by weight of LDPE, 5 parts by weight of POE, 1.2 parts by weight of trimethylchlorosilane, 0.8 parts by weight of aluminum trichloride and 2 parts by weight of talcum powder, and then put into Melt and mix in a twin-screw extruder, the body temperature of the extruder is 220° C., and the rotation speed is 50 rpm. Inject 6 parts by weight of foaming agent into the polymer melt in the middle section of the extruder, and mix the foaming agent and various components evenly under the action of the twin-screw, and further mix the ingredients uniformly with the help of a static mixer , lower the temperature to 180°C, pressurize the melt pump, extrude the polymer melt at 80kg / h under a pressure of 200kg, and pelletize it through an underwater pelletizer. During granulation, the aperture of the die is 0.4mm, the water temperature is 40°C, and the water pressure is 3 kg. Expandable EPO particles containing foaming agent and narrow particl...

Embodiment 2

[0034] The raw materials are basically the same as in Example 1, and 4 parts by weight of styrene monomer and 5 parts by weight of SBS are added in the raw material premixing stage. All the other steps and technology are identical with embodiment 1. The performance indexes of the expanded particles prepared in this example are shown in Table 1.

Embodiment 3

[0036] The raw materials are basically the same as in Example 1, 3 parts by weight of styrene monomer and 1 part by weight of acrylic acid monomer are added in the raw material premixing stage, and trimethylchlorosilane and aluminum trichloride are not added at the same time. All the other steps and technology are identical with embodiment 1. The performance indexes of the expanded particles prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com