Solid pulse plasma thruster with high propellant utilization rate and working method

A technology of pulsed plasma and plasmoid, which is applied in the field of microsatellite space propulsion, can solve problems such as low work efficiency, and achieve the effects of improving utilization rate, improving success rate, and increasing forward speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

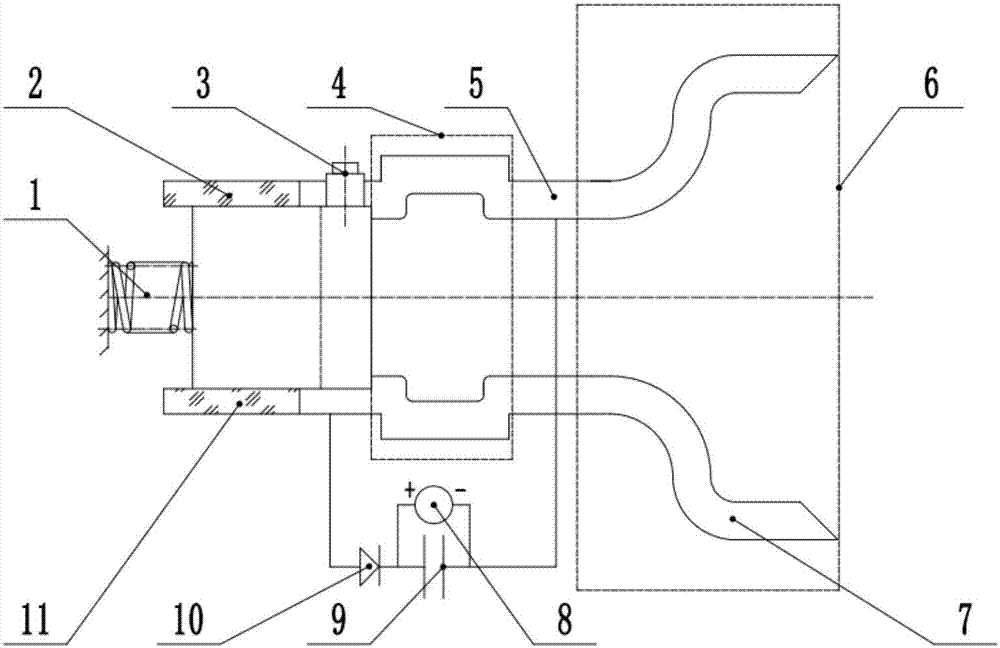

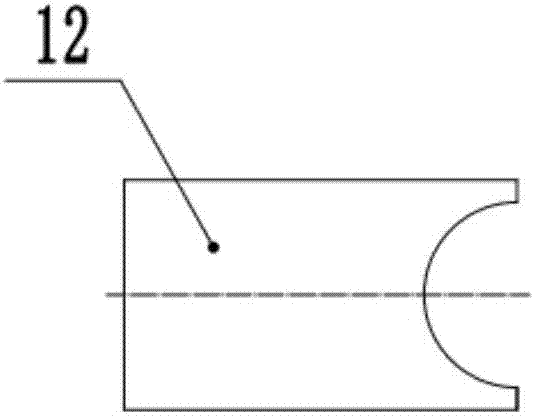

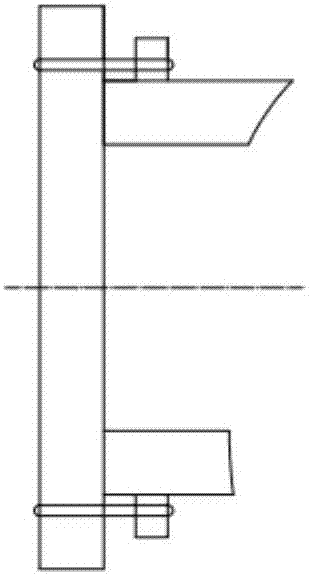

[0023] This embodiment discloses a solid pulse plasma thruster with high propellant utilization rate, which includes a constant force spring 1, an upper insulating plate 2 for fixing the propellant, a semiconductor spark plug 3, a permanent magnet 4 for increasing the primary impulse, and a cathode plate 5 , increase specific impulse with permanent magnet 6, anode plate 7, high voltage power supply 8, main discharge capacitor 9, diode 10, lower insulating plate 11, solid propellant 12 that fixed propellant is used. Among them, the cathode plate 5 and the anode plate 7 are copper electrodes with a total length of 20 mm and good electrical conductivity, the length of the neutral gas storage chamber is 5 mm, the height of the storage chamber is 5-10 mm, and the acceleration area of the plate is 10 mm. , according to specific working conditions, the width of the pole plate can be adjusted to 20 ~ 40mm, and the minimum distance between the pole plates can be adjusted to 25 ~ 40mm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com