Formation method of nano coating of lithium ion battery membrane

A lithium-ion battery and nano-coating technology, which is applied in secondary batteries, battery components, circuits, etc., can solve the problems affecting the electrochemical performance of the diaphragm conductivity, lithium-ion diaphragm plugging, battery conductivity and lithium ion migration. problems such as decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

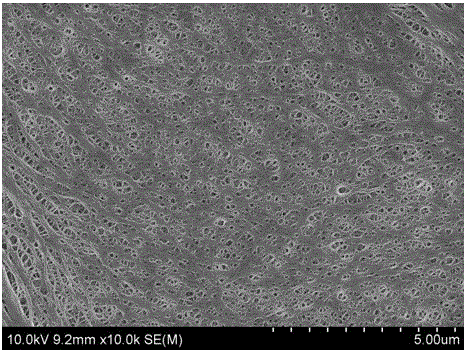

Image

Examples

Embodiment 1

[0022] A method for forming a lithium-ion battery diaphragm nano-coating, the steps are as follows:

[0023] (1). Dissolve 1.0g of water-based polyurethane and 0.2g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer P123 in deionized water, and stir for 3h to obtain a water-based polyurethane mixed solution ;

[0024] (2). 15.0g of water-based zirconia with a solid content of 30% was added to the water-based polyurethane mixed solution obtained in step (1), continued to stir for 2h, and left to stand for 1h to obtain a water-based nano-coating coating, wherein the The components and their weight percentages in the water-based nano-coating paint are: polyurethane, 5.5%; polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer P123, 1.1%; zirconia nano Sol, 23%; Deionized water 70.4%;

[0025] (3). Using the traditional dip-coating method, the polyethylene diaphragm is first placed in a plasma treatment device for treatment. The...

Embodiment 2

[0027] A method for forming a lithium-ion battery diaphragm nano-coating, the steps are as follows:

[0028] (1). Dissolve 1.4g of hydroxyethyl cellulose and 0.3g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer P123 in deionized water, stir for 3h, and obtain an aqueous Hydroxyethyl cellulose mixed solution;

[0029] (2). 25.0g of water-based titanium oxide with a solid content of 18% was added to the water-based hydroxyethyl cellulose mixed solution obtained in step (1), continued to stir for 2 hours, and left to stand for 1 hour to obtain a water-based nano-coating coating;

[0030] Wherein, each component and its weight percent content in the described water-based nano-coating paint are: hydroxyethyl cellulose, 5.9%; polyethylene oxide-polypropylene oxide-polyethylene oxide tri-block copolymer Material P123, 1.5%; Titanium oxide nano-sol, 19%; Deionized water, 73.6%;

[0031] (3). Using the traditional dip coating method, first place the po...

Embodiment 3

[0033] A method for forming a lithium-ion battery diaphragm nano-coating, the steps are as follows:

[0034] (1). The carboxymethyl cellulose of 1.5g and the polyimide of 0.5g are dissolved in deionized water, stirred for 3h to obtain an aqueous carboxymethyl cellulose mixed solution;

[0035] (2). Add 28g of silicon oxide with a solid content of 18% into the aqueous carboxymethylcellulose mixed solution obtained in step (1), continue to stir for 2h, and leave it for 1h to obtain a nano-coating coating;

[0036] Wherein, each component and weight percent content thereof in the described water-based nano-coating paint are: carboxymethyl cellulose, 5.4%; polyimide, 1.8%; silica nano-sol, 18%, deionized water, 74.8%;

[0037] (3). Using the traditional dip coating method, first place the polyethylene diaphragm in a plasma treatment device for treatment, the treatment power is 80 W, and the flow rate is 20 ml / min. 2 Gas, treated for 60s, then, the water-based nano-coating coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com