Extraction method of dendrobium officinale leave, extract of dendrobium officinale leave and application of extract of dendrobium officinale leave

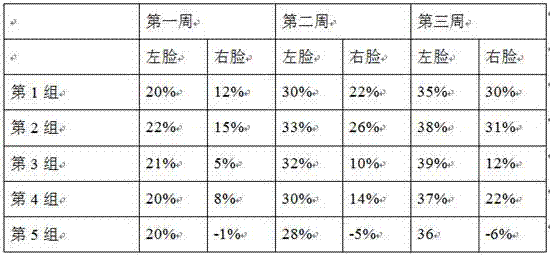

A technology of Dendrobium officinale and an extraction method, which is applied in the directions of skin care preparations, medical preparations containing active ingredients, drug combinations, etc., can solve the problem that the utilization efficiency of Dendrobium officinale leaves, the extraction yield and the purity of functional components cannot be improved, and the use of Low efficiency and other problems, to achieve more compact and elastic skin, improve acne and pigmentation, improve anti-aging and antioxidant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for extracting dendrobium officinale leaves, comprising the steps of:

[0052] (1) Slurry: take the Dendrobium candidum leaf slurry, the Dendrobium candidum leaf slurry is composed of Dendrobium candidum leaf powder and water, wherein, the parts by weight of the Dendrobium candidium leaf powder and water in the Dendrobium candidium leaf slurry are 20 parts and 75 parts respectively share;

[0053] (2) Repeated freezing and thawing: the dendrobium candidum leaf slurry was cooled to -10°C, kept for 24 hours, then heated to 100°C, kept for 2 hours, then cooled to -10°C, kept for 24 hours, and then heated to a slurry state;

[0054] (3) Enzymolysis: adding protease to the Dendrobium officinale leaf slurry after repeated freezing and thawing in the step (2) for enzymolysis reaction, wherein the protease is papain, and the amount of the protease is 2.5 parts by weight. The temperature is 45°C, and the enzymatic hydrolysis time is 4h;

[0055] (4) Inactivation: heat...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is:

[0059] A method for extracting dendrobium officinale leaves, comprising the steps of:

[0060] (1) Slurry: Take the Dendrobium candidum leaf slurry, the Dendrobium candidum leaf slurry is composed of Dendrobium candidum leaf powder and water, wherein, the parts by weight of the Dendrobium candidium leaf powder and water in the Dendrobium candidium leaf slurry are 1 part and 50 parts respectively share;

[0061] (2) Repeated freezing and thawing: cooling the Dendrobium officinale leaf slurry to -20°C, keeping it warm for 12 hours, then heating to 80°C, keeping it warm for 1 hour, then cooling to -20°C, keeping it warm for 12 hours, and then heating up to a slurry state;

[0062] (3) Enzymolysis: adding protease to the Dendrobium candidum leaf slurry after repeated freezing and thawing in the step (2) for enzymolysis reaction, wherein the protease is bromelain, and the amount of the protease is 0.1 parts by we...

Embodiment 3

[0066] The difference between this embodiment and embodiment 1 is:

[0067] A method for extracting dendrobium officinale leaves, comprising the steps of:

[0068] (1) Slurry: Take the Dendrobium candidum leaf slurry, the Dendrobium candidum leaf slurry is composed of Dendrobium candidum leaf powder and water, wherein the weight parts of Dendrobium candidium leaf powder and water in the Dendrobium candidium leaf slurry are 40 parts and 98 parts respectively share;

[0069] (2) Repeated freezing and thawing: cooling the Dendrobium candidum leaf slurry to 0°C, keeping it warm for 36 hours, then heating it to 90°C, keeping it warm for 3 hours, then cooling it to 0°C, keeping it warm for 36 hours, and then heating it up to a slurry state;

[0070] (3) Enzymolysis: adding protease to the Dendrobium officinale leaf slurry after repeated freezing and thawing in the step (2) for enzymolysis reaction, wherein the protease is composed of papain and bromelain in a weight ratio of 1:1 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com