Polyvinyl alcohol hydrogel and preparation method thereof

A technology of polyvinyl alcohol and hydrogel, which is applied in the field of biomaterials and artificial articular cartilage replacement materials, and can solve the problems of difficulty in obtaining polyvinyl alcohol hydrogel, time-consuming removal of pore-forming agents, and easy residue of pore-forming agents. Achieve the effects of avoiding chemical residues and biological toxicity, good biocompatibility, and easy control of process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

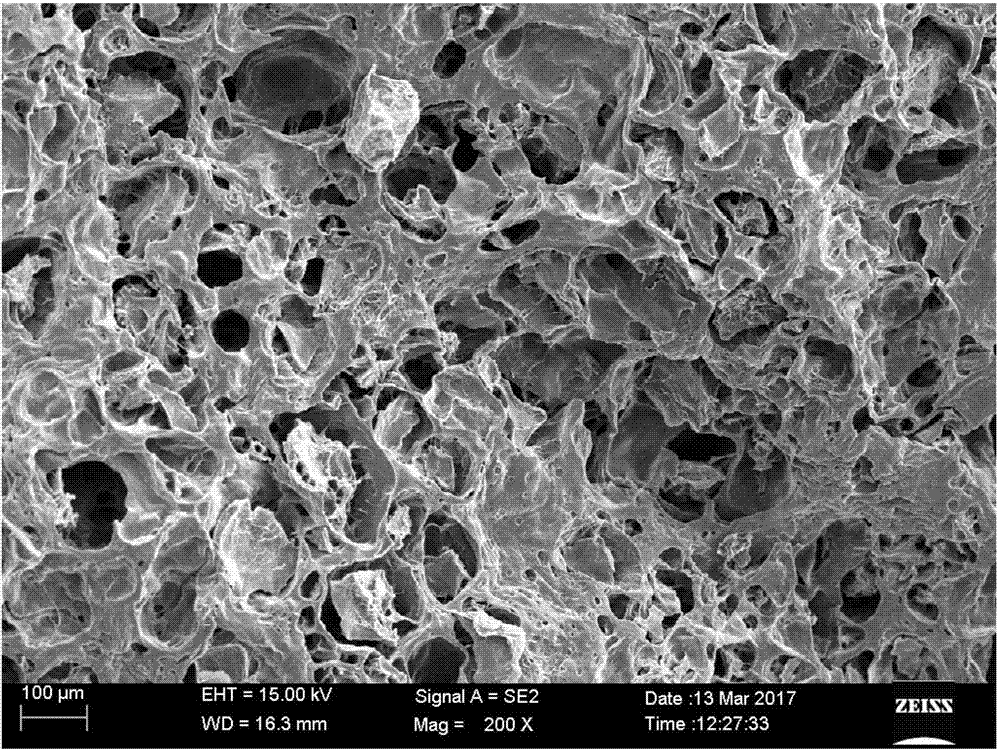

Embodiment 1

[0024] In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95° C. for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and shape. Set the freezing temperature to -20°C and the time to 16 hours, take out the sample to thaw, the thawing temperature to 18°C, and the thawing time to 8 hours. Repeat the freezing and thawing process above to prepare a physically cross-linked PVA hydrogel...

Embodiment 2

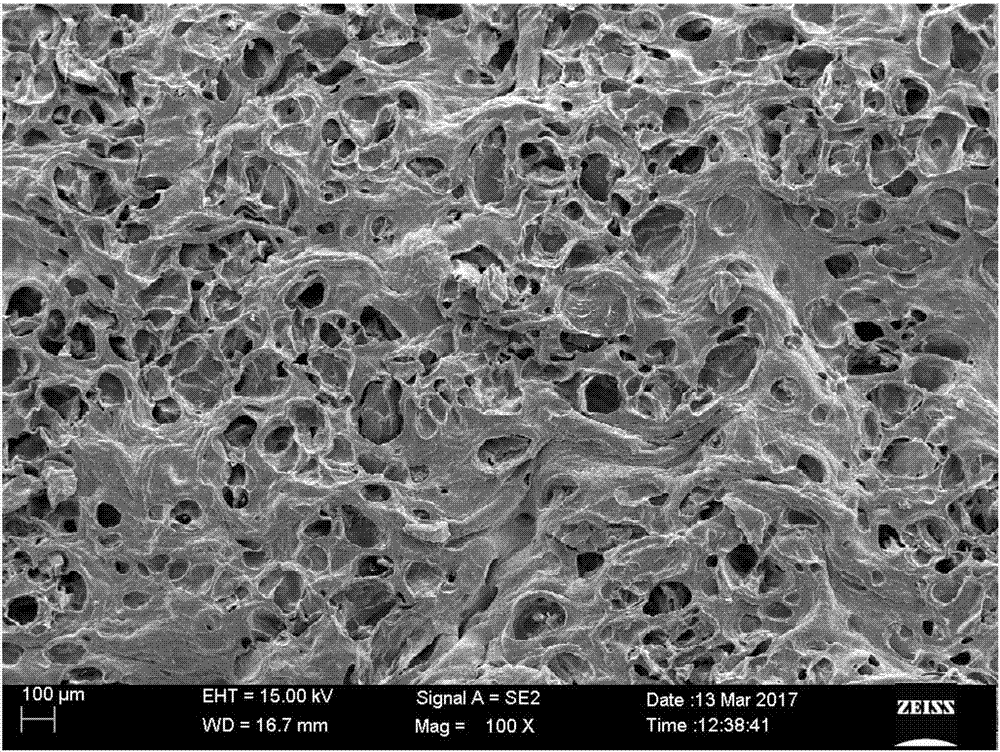

[0032] Further, in order to enhance the crystallinity of the PVA molecules in the PVA hydrogel, steps such as liquid freezing can also be added to the above-mentioned preparation method of the polyvinyl alcohol hydrogel.

[0033] (1) In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95°C for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and form. Set the freezing temperature t...

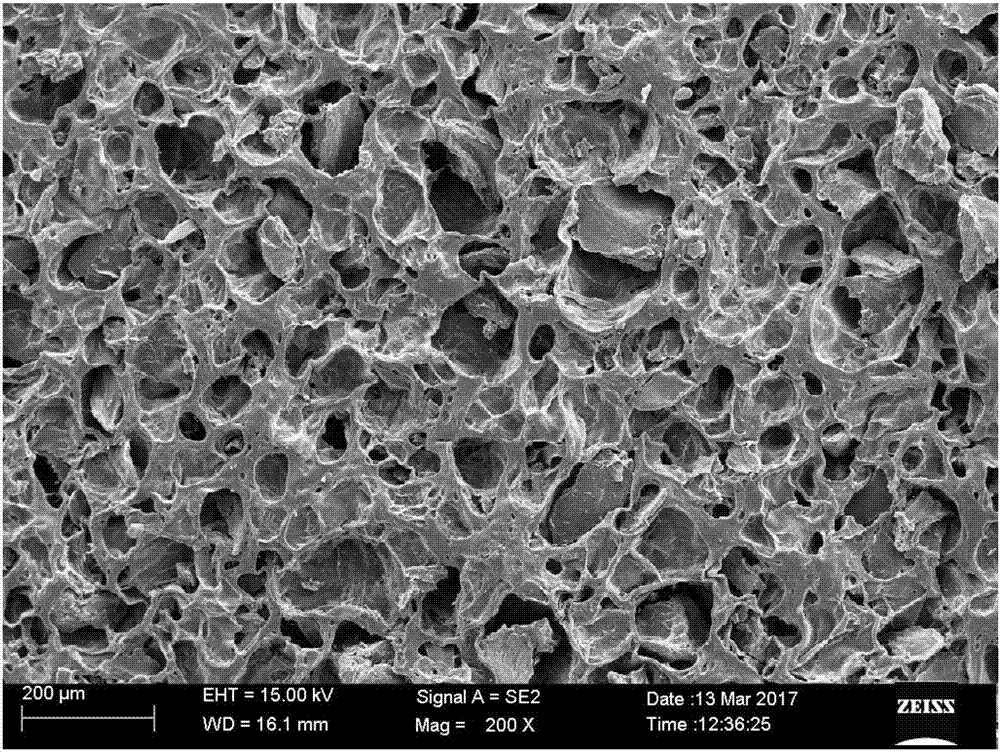

Embodiment 3

[0039] Further, in order to improve the pore structure in the PVA hydrogel, steps such as desugaring can also be added to the above-mentioned preparation method of the polyvinyl alcohol hydrogel.

[0040] (1) In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95°C for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and shape. Set the freezing temperature to -20°C and the time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com