Polyvinyl alcohol hydrogel and preparation method thereof

A technology of polyvinyl alcohol and hydrogel, applied in prosthetics, medical science, etc., can solve the problems of difficult to obtain polyvinyl alcohol hydrogel, time-consuming removal of pore-forming agents, easy residue of pore-forming agents, etc., to avoid Effects of chemical residues and biological toxicity, good biocompatibility, and easy control of process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

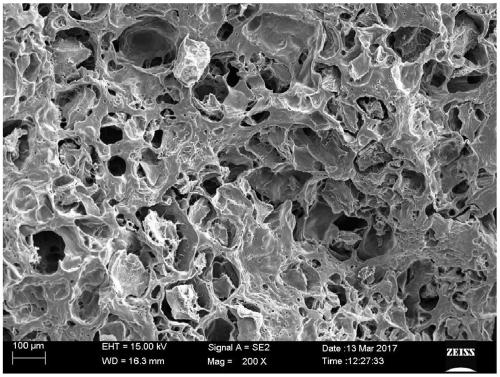

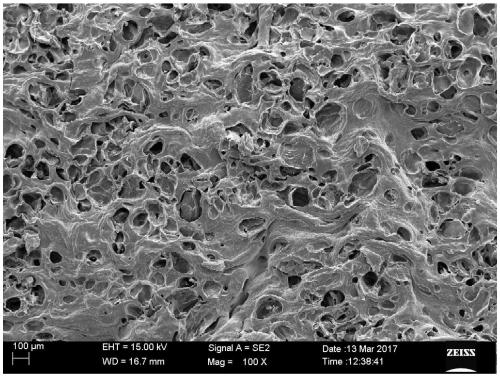

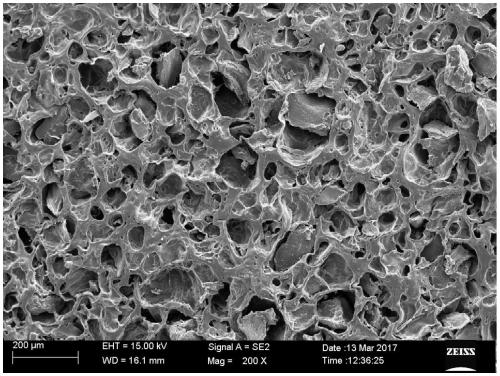

Image

Examples

Embodiment 1

[0024] In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95° C. for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and shape. Set the freezing temperature to -20°C and the time to 16 hours, take out the sample to thaw, the thawing temperature to 18°C, and the thawing time to 8 hours. Repeat the freezing and thawing process above to prepare a physically cross-linked PVA hydrogel...

Embodiment 2

[0032] Further, in order to enhance the crystallinity of the PVA molecules in the PVA hydrogel, steps such as liquid freezing can also be added to the above-mentioned preparation method of the polyvinyl alcohol hydrogel.

[0033] (1) In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95°C for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and form. Set the freezing temperature t...

Embodiment 3

[0039] Further, in order to improve the pore structure in the PVA hydrogel, steps such as desugaring can also be added to the above-mentioned preparation method of the polyvinyl alcohol hydrogel.

[0040] (1) In the first step, weigh 15 parts by weight of PVA and add it to 81 parts by weight of deionized water, stir and heat at a constant temperature of 95°C for 2 hours until the PVA is completely melted to form an aqueous solution of polyvinyl alcohol. In the second step, slowly add 4 parts by weight of agarose, keep heating and stirring at a constant temperature of 95°C for 2 hours until the agarose is completely dissolved and uniformly mixed with the PVA aqueous solution to obtain 15 wt% of PVA and 4 wt% of AG mixed solution. The third step is to pour the prepared mixed solution into the mold, put it into a vacuum drying oven for degassing for 2 hours, and then put it into a low-temperature freezer to freeze and shape. Set the freezing temperature to -20°C and the time to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com