Multifunctional compressing composite unit and method for manufacturing microprism film

A multi-functional, multi-layer composite technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as component loss, and achieve the effect of reducing the difficulty of operation, improving running speed and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

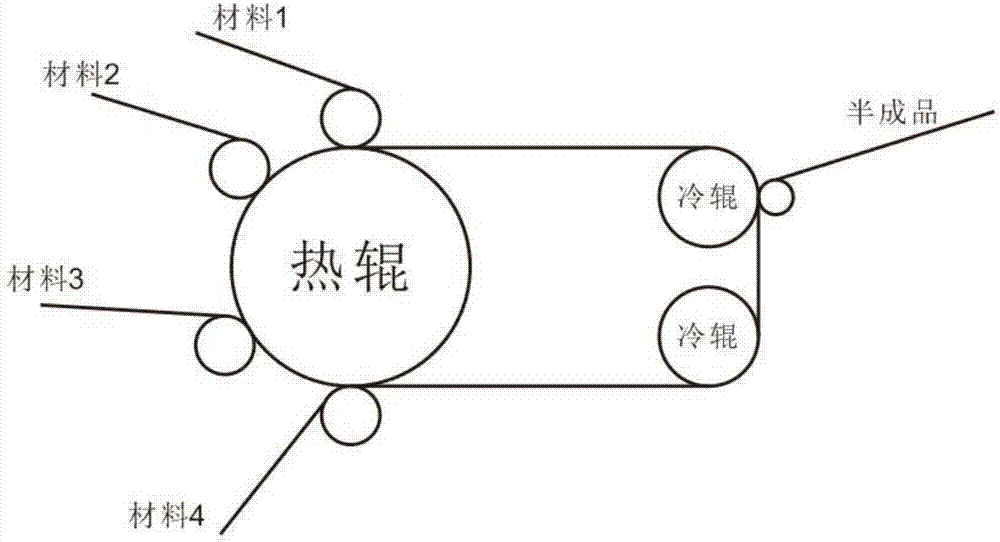

Embodiment 1

[0038] image 3 It shows a schematic structural view of Embodiment 1 of the multi-functional press molding compound unit provided by the present invention. The multi-functional pressing compound unit includes two sets of heating rolls and two sets of cooling rolls. Wherein, one group of heating rollers is the upper pressing type roller 11, and its temperature is set to 240~350 ℃, as the thermocompression molding heating roller of microscopic structure such as microprism. Another group of heating rollers is the lower multi-layer composite roller 12, and its temperature is set at 180~330 ℃, as the composite heating roller of multi-layer material. Two sets of heating rollers with different temperatures realize the function of setting different temperatures in different processing areas. Two groups of hydraulic rubber rollers 4 are configured for each group of heating rollers. The temperature settings of the two groups of cold rollers 2 are all kept below 18°C, so as to ensure ...

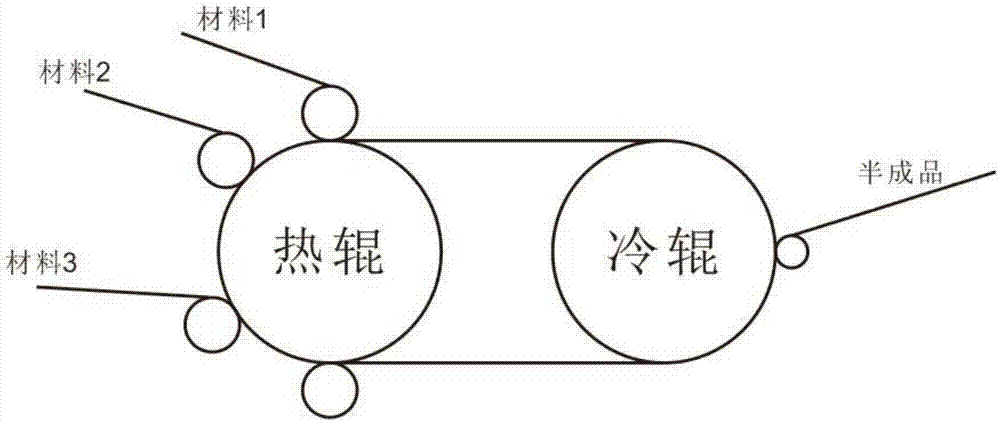

Embodiment 2

[0041] Figure 4 A schematic structural view of Embodiment 2 of the multi-functional press molding compound unit provided by the present invention is shown. The difference from Embodiment 1 lies in that the multi-functional press molding compound unit includes a set of chill rolls. Using a set of chilled rolls, the material is rapidly cooled and shaped on a set of chilled rolls, with fast cooling speed and high efficiency. It is suitable for processing soft resins such as polyvinyl chloride and polysulfone, while processing hard resins such as polymethyl methacrylate and polycarbonate is prone to residual stress and the product is easily deformed.

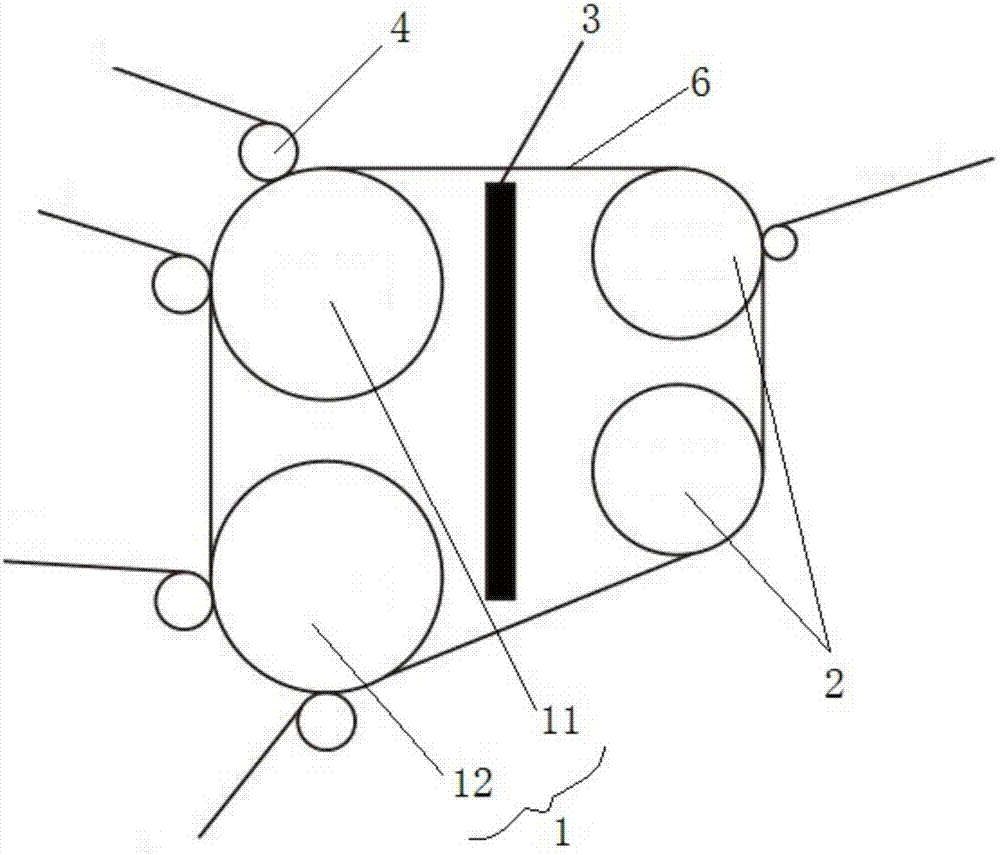

Embodiment 3

[0043] Figure 5 A schematic structural view of Embodiment 3 of the multi-functional press molding compound unit provided by the present invention is shown. The difference from Embodiment 1 lies in that the multi-functional molding compound unit also includes a bearing bar 5, which is arranged between two sets of heating rollers. In the process of loading and unloading the endless mold steel belt, the load-bearing rod can cooperate with the supporting parts and hydraulic lifters (not shown in the drawings) on both sides of the multi-functional molding compound unit, and the heating roller and the cold roller are pressed by the endless mold steel belt. The wrapped part is jacked up, and the old endless mold steel strip is withdrawn from the work area, and the new endless mold steel strip is moved to the work area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com