Pentafluoroethane purification method

A pentafluoroethane and purification method technology, applied in the field of pentafluoroethane purification, can solve the problems of difficulty in improving the purity of HFC-125 products, purification of HFC-125, and insufficient extraction and separation efficiency, and achieve simple structure and high process efficiency. Simple and effective in improving extraction and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

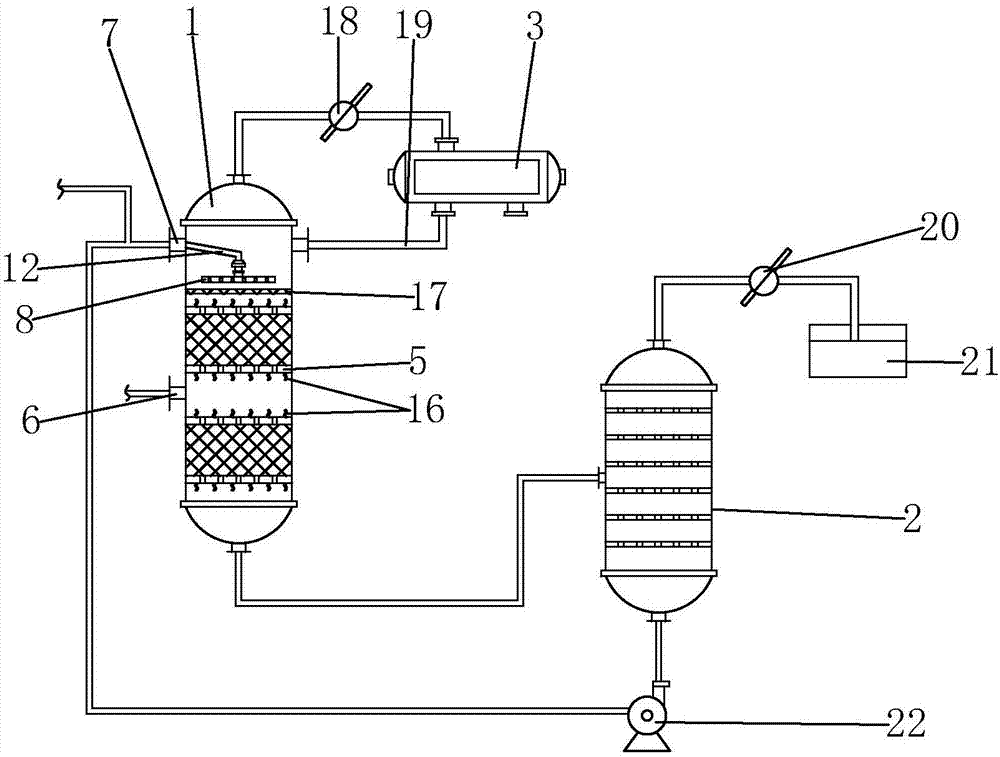

[0025] Such as Figure 1 to Figure 3 Shown, be the purification method of a kind of pentafluoroethane of the present invention, comprise the steps:

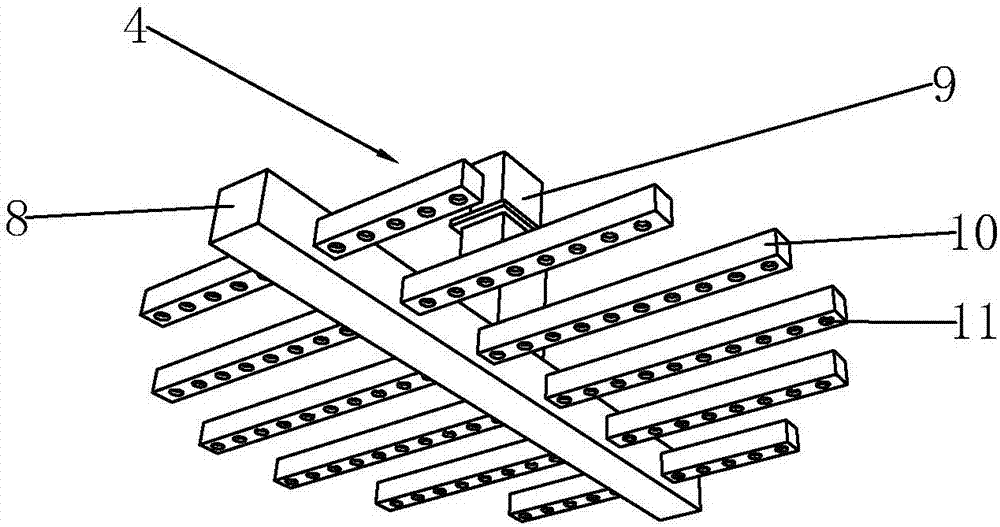

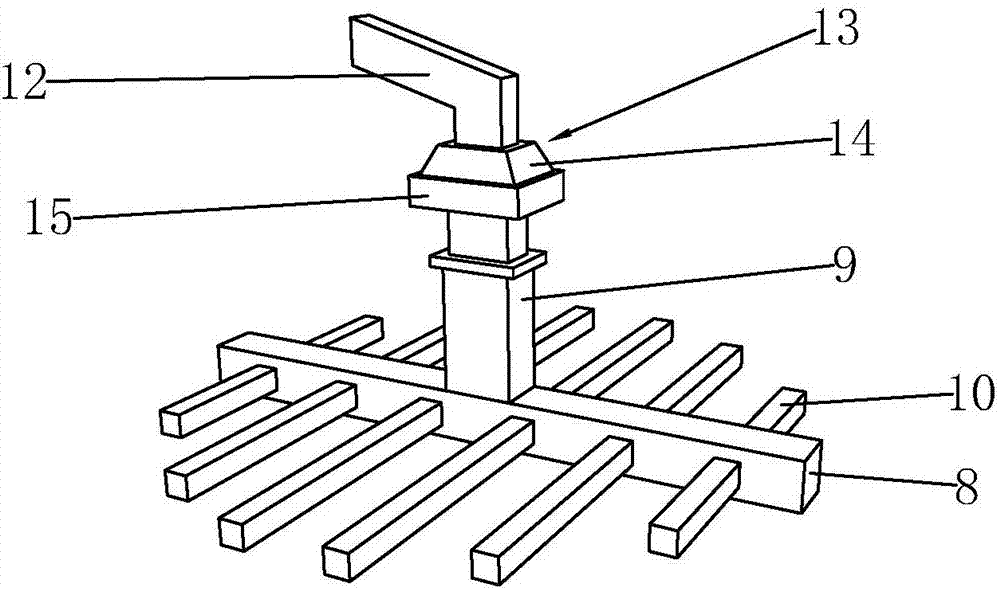

[0026] (a) Preliminary reaction device: first check the airtightness of rectification tower 1, distillation tower 2, reflux tank 3 and fixed bed reactor by conventional methods, install liquid distributor 4 in rectification tower 1, and evenly arrange rectification Packing in tower 1 and distillation tower 2, and then preheating rectification tower 1 and distillation tower 2 to avoid air leakage in the device during operation and affect the yield of the product. The effect, thereby improving the purity of the finished product, preheating the device in advance can effectively reduce the extraction time, speed up the separation efficiency, and reduce energy consumption. The rectification column 1 is provided with a support grid 5, which is located below the liquid distributor 4, and a stainless steel corrugated wire mesh structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com