Processing method for garlic oil

A processing method and garlic oil technology, applied in the field of feed additives, can solve the problems of high temperature requirements, variable activity, low yield and the like, and achieve the effects of simplifying synthesis process operations, shortening process time, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

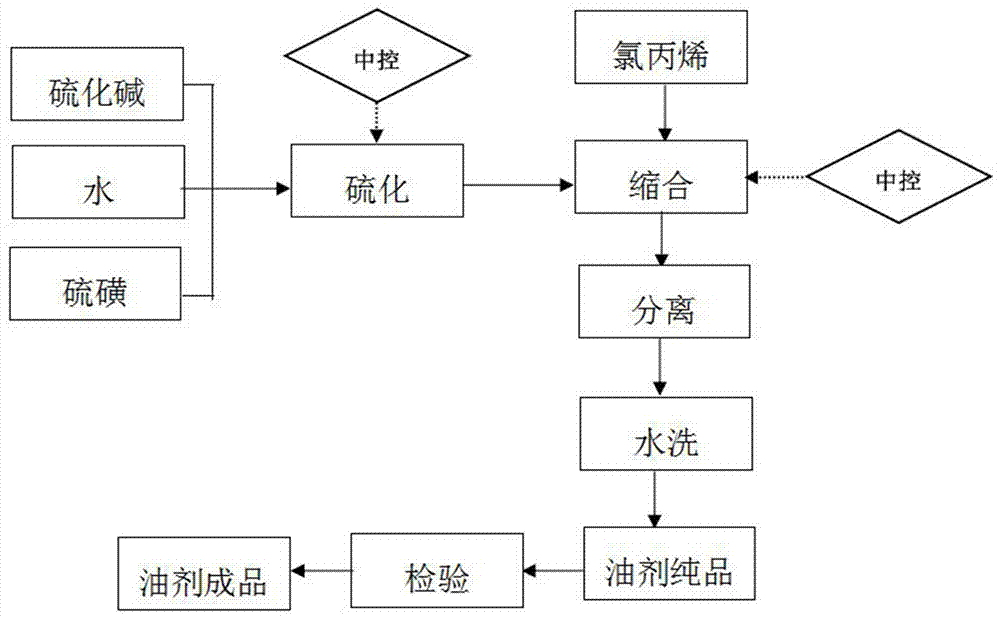

Method used

Image

Examples

Embodiment 1

[0021] (1) Synthesis of polysulfides

[0022] Vulcanization reaction: first rinse the reactor with tap water, add 2000kg of tap water to the reactor, start stirring, and mix 450kg of sodium sulfide (in which the content of sodium sulfide is ≥60%; the content of sodium sulfite is ≤2.0, and the content of sodium thiosulfate is ≤2.0)) Put into the reaction kettle, add steam into the jacket at the same time, raise the temperature of the material in the kettle to 60°C, slowly add 250kg of sulfur into the reaction kettle, close the device after adding, continue to heat up to 85°C, the solution is transparent dark brown , constant temperature reaction for 1 hour, and then gradually lower the temperature to 30°C.

[0023] Condensation reaction: keep the temperature constant at 30°C, slowly add 500kg of chloropropene to the reaction kettle, the addition of chloropropene should not be too fast, keep the temperature at 30°C and continue to stir for half an hour, then add steam to the jac...

Embodiment 2

[0029] (1) Synthesis of polysulfides

[0030] Vulcanization reaction: first rinse the reactor with tap water, add 2200kg of tap water to the reactor, start stirring, add 490kg of sodium sulfide (the content of sodium sulfide is ≥60%; the content of sodium sulfite is ≤2.0, and the content of sodium thiosulfate is ≤2.0) Reactor, add steam into the jacket at the same time, raise the temperature of the material in the kettle to 65°C, slowly add 250kg of sulfur into the reactor, close the device after adding, continue to heat up to 88°C, the solution is transparent dark brown, React at constant temperature for 1 hour, then gradually lower the temperature to 35°C.

[0031] Condensation reaction: keep the temperature constant at 35°C, slowly add 650kg of chloropropene to the reaction kettle, the addition of chloropropene should not be too fast, keep the temperature and continue the reaction for half an hour after the addition, and then add steam to the jacket to heat the material to ...

Embodiment 3

[0036] (1) Synthesis of polysulfides

[0037] Vulcanization reaction: first rinse the reactor with tap water, add 2400kg of tap water to the reactor, start stirring, add 510kg of sodium sulfide (the content of sodium sulfide≥60%; the content of sodium sulfite≤2.0, sodium thiosulfate≤2.0) Reactor, add steam into the jacket at the same time, raise the temperature of the material in the kettle to 68°C, slowly add 250kg of sulfur into the reactor, close the device after adding, continue to heat up to 90°C, the solution is transparent dark brown, React at constant temperature for 1 hour, then gradually lower the temperature to 30°C.

[0038] Condensation reaction: keep the temperature constant at 30°C, slowly add 680kg of allyl chloride to the reactor, the addition of allyl chloride should not be too fast, keep the temperature at 30°C and continue the reaction for half an hour, then add steam to the jacket to heat the material to 42°C React at constant temperature for 2 hours, tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com