Acrylate hydrophilic monomer synthesized by using monoisocyanate polyoxyethylene monomethyl ether

A technology of polyoxyethylene monomethyl ether and monoisocyanate, which is applied in the field of water-based acrylic resin, can solve the problems of reducing the water resistance and salt spray resistance of the coating film, poor storage stability, and easy delamination, etc., and achieve salt spray resistance Excellent, not easily hydrolyzed, excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

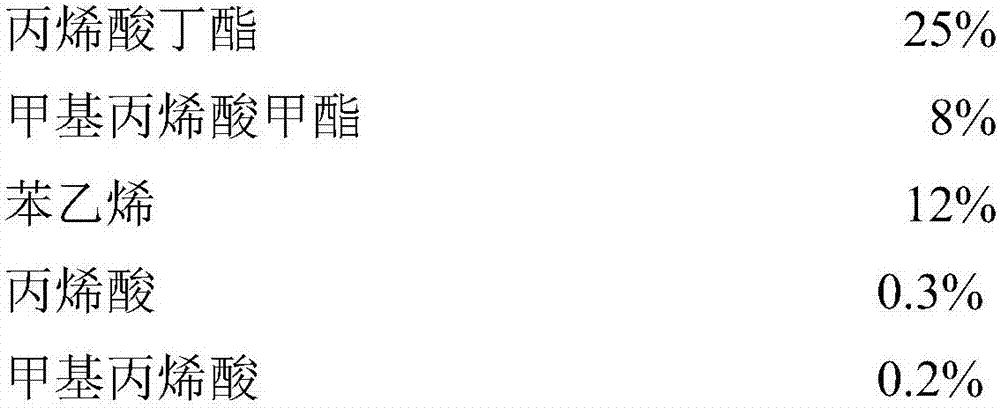

[0020] (1) The acrylate hydrophilic monomer is made from the following raw materials in mass percentage:

[0021] Hydroxyethyl Acrylate 15%

[0022] Monoisocyanate polyoxyethylene monomethyl ether 85%

[0023] Mix hydroxyethyl acrylate and monoisocyanate polyoxyethylene monomethyl ether, and raise the temperature to 60-65°C to react for 5 hours to obtain acrylate hydrophilic monomer.

[0024] (2) The monoisocyanate polyoxyethylene monomethyl ether monomer is made of the following raw materials in mass percentage:

[0025] 2,4-Toluene diisocyanate 20%

[0026] Polyethylene glycol monomethyl ether 80%

[0027] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 60-65°C for 8 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether monomer.

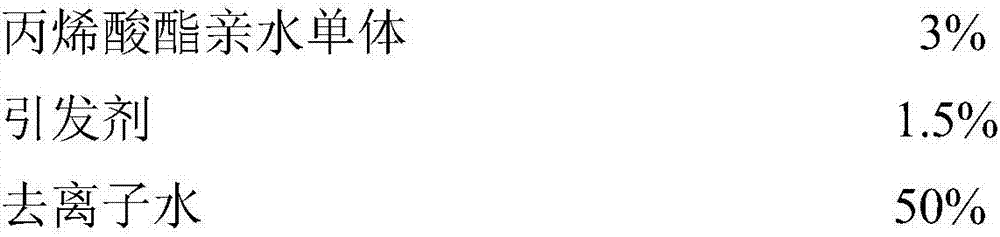

Embodiment 2

[0029] (1) The acrylate hydrophilic monomer is made from the following raw materials in mass percentage:

[0030] Hydroxyethyl Acrylate 18%

[0031] Monoisocyanate polyoxyethylene monomethyl ether 82%

[0032] Mix hydroxyethyl acrylate and monoisocyanate polyoxyethylene monomethyl ether, and raise the temperature to 75-80°C to react for 4 hours to obtain acrylate hydrophilic monomer.

[0033] (2) The monoisocyanate polyoxyethylene monomethyl ether monomer is made of the following raw materials in mass percentage:

[0034] 2,4-Toluene diisocyanate 25%

[0035] Polyethylene glycol monomethyl ether 75%

[0036] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 65-70°C for 6 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether monomer.

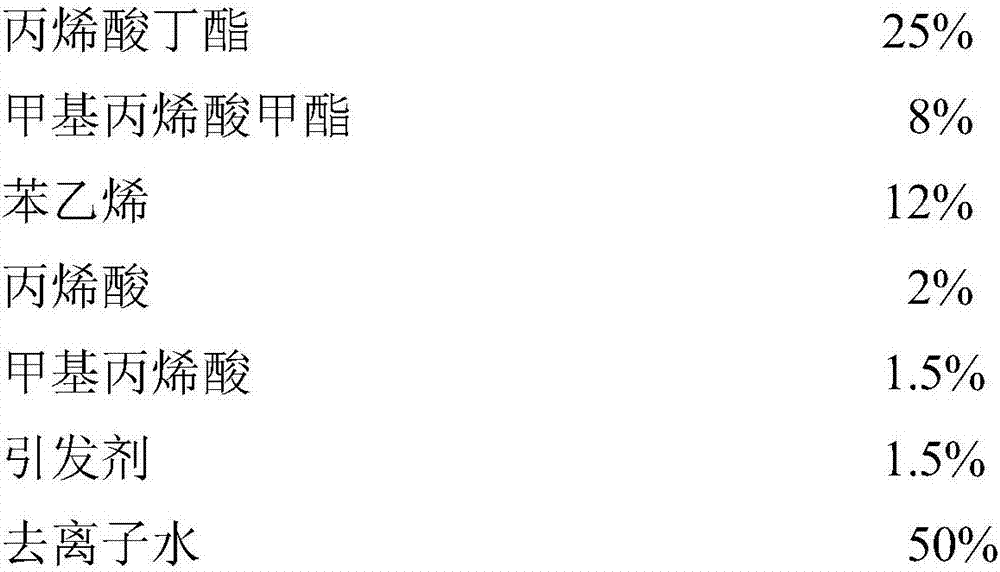

Embodiment 3

[0038] (1) The acrylate hydrophilic monomer is made from the following raw materials in mass percentage:

[0039] Hydroxyethyl Acrylate 20%

[0040] Monoisocyanate polyoxyethylene monomethyl ether 80%

[0041] Mix hydroxyethyl acrylate and monoisocyanate polyoxyethylene monomethyl ether, and raise the temperature to 70-75°C for 5 hours to obtain the acrylate hydrophilic monomer.

[0042] (2) The monoisocyanate polyoxyethylene monomethyl ether monomer is made of the following raw materials in mass percentage:

[0043] 2,4-Toluene diisocyanate 15%

[0044] Polyethylene glycol monomethyl ether 85%

[0045] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 70-75°C for 6 hours, and cool down to room temperature naturally to obtain monoisocyanate polyoxyethylene monomethyl ether monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com