Janus club-shaped nanometer material and preparing method thereof

A nano-material and rod-shaped technology, applied in the field of materials, can solve problems such as low efficiency and output, and can not meet actual needs, and achieve the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned functional composite nanorods, for example, may include the following steps:

[0048] Step 1) using a free radical polymerization method to synthesize a three-block copolymer in which the middle segment is a reactive polymer molecular brush segment, and the two ends are respectively a hydrophilic polymer segment and a hydrophobic polymer segment;

[0049] Step 2) Utilize the reactive groups carried by the reactive polymer molecular brush segment of the above-mentioned tri-block copolymer to grow composite functional substances to obtain nanoparticles with different properties at both ends, the two ends are respectively Hydrophilic polymer segments and hydrophobic polymer segments.

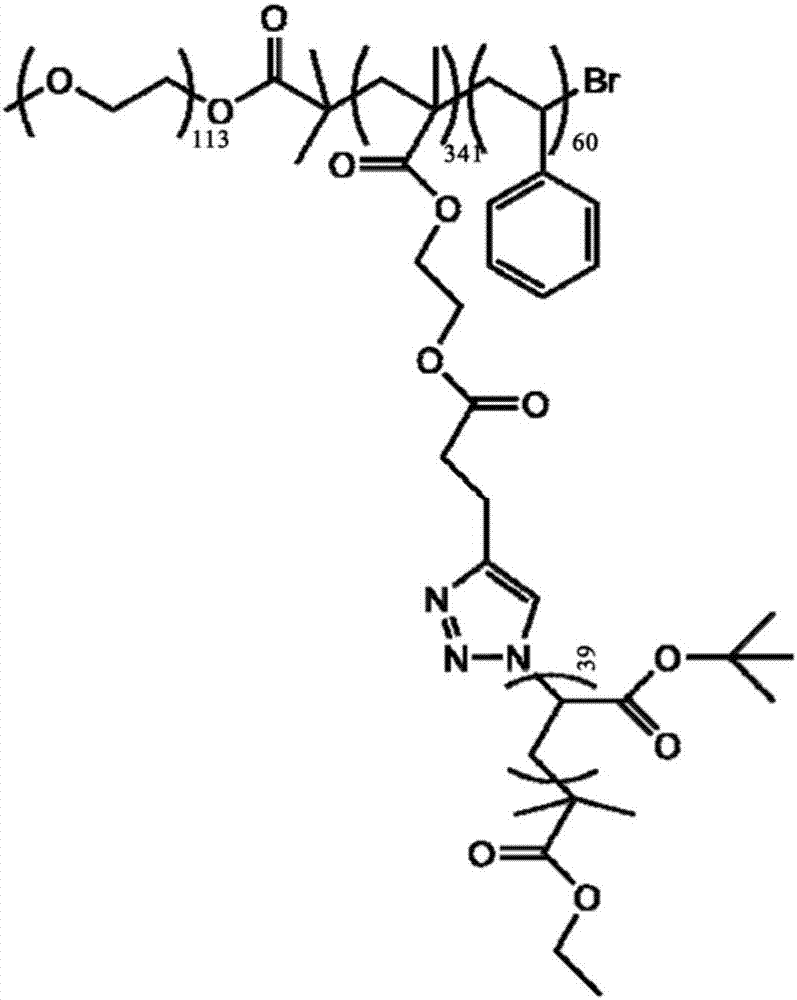

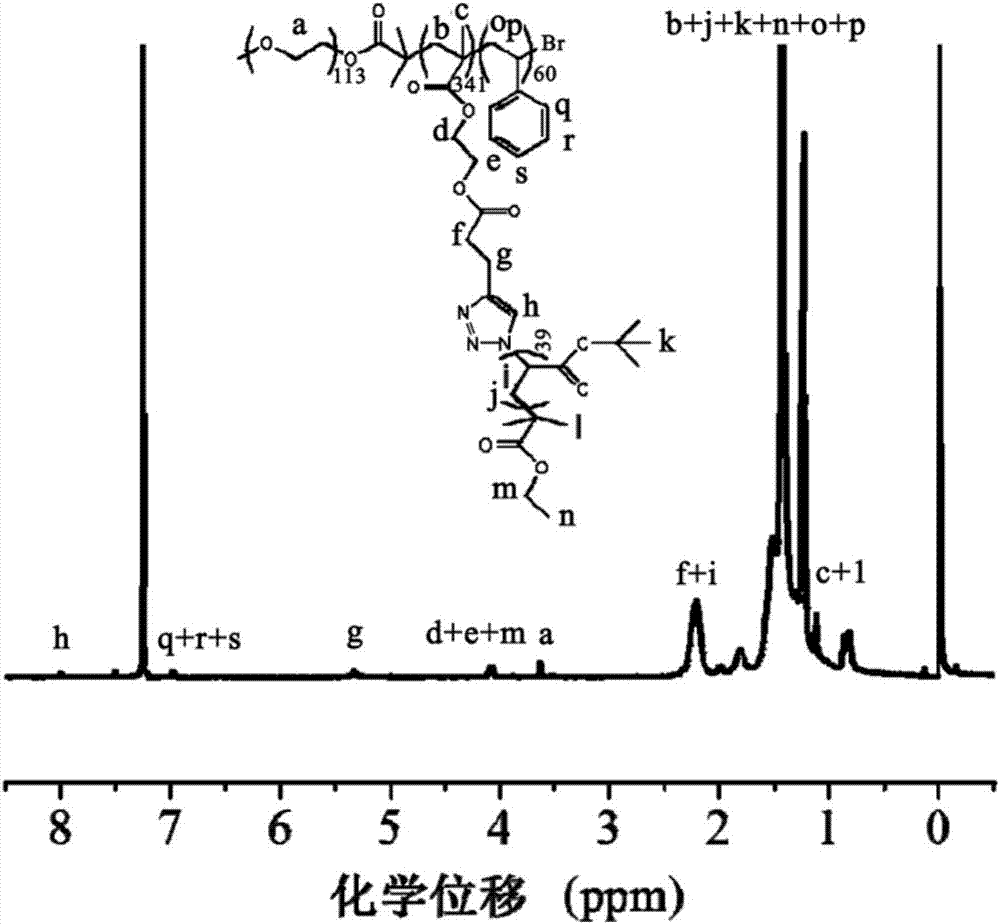

[0050] Regarding the preparation method of the above-mentioned three-block copolymer, for example, the intermediate segment can be synthesized as polyacrylic acid by the grafting-onto method by combining atom transfer radical polymerization and c...

Embodiment 1

[0115] Embodiment 1, the preparation of Janus rod-shaped nanomaterial

[0116] Prepare Janus rod-shaped nanomaterials according to the following steps:

[0117] 1. Preparation of Au composite nanorod embedded ball material

[0118] Step 1) ultrasonically disperse 1 mg of Au composite nanorods in 100 g of water, add 5 g of paraffin (melting point is 50-52 ° C) at 70 ° C, emulsify for 5 min under the action of ultrasound, and the ultrasonic power is 100 W, to obtain a stable paraffin / water emulsion .

[0119] Step 2) cooling the above paraffin / water emulsion to room temperature, washing with water to remove the Au composite nanorods in the water phase, and obtaining the Au composite nanorod embedded ball material. The surface morphology was characterized by scanning electron microscopy, such as Image 6 shown.

[0120] 2. Preparation of Janus rod-shaped nanomaterials

[0121] Step 1) Take 2mg of the Au composite nanorod embedding ball material obtained in Example 1 and disp...

Embodiment 2

[0123] Embodiment 2, the preparation of Janus rod-shaped nanomaterial

[0124] Prepare Janus rod-shaped nanomaterials according to the following steps:

[0125] 1. Preparation of silica composite nanorod embedded ball material

[0126]Step 1) ultrasonically disperse 1 mg of silica composite nanorods in 100 g of water, add 5 g of paraffin (melting point is 50-52 ° C) at 70 ° C, emulsify for 5 min under ultrasonic action, and the ultrasonic power is 100 W to obtain stable paraffin / water emulsion.

[0127] Step 2) cooling the above paraffin / water emulsion to room temperature, washing with water to remove the silica composite nanorods in the water phase, to obtain a silica composite nanorod embedded ball material. The surface morphology was characterized by scanning electron microscopy, such as Figure 8 shown.

[0128] 2. Preparation of Janus rod-shaped nanomaterials

[0129] Step 1) Take 2 mg of the silica composite nanorod embedded ball material obtained in Example 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com