Zirconium-titanium-nickel alloy and preparation method thereof

A technology of nickel alloy and zirconium titanium, which is applied in the field of alloy and its preparation, can solve the problems that mechanical properties such as strength cannot meet the requirements well, and achieve the effect of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

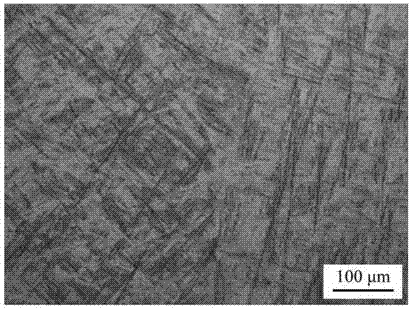

[0017] Take 29.7g of pure zirconium wire, 29.7g of pure titanium wire, and 0.6g of pure nickel wire, and place them in a non-consumable vacuum arc melting furnace for repeated melting for 6 times, each melting time is 3 minutes, and the melting electrode current is kept at 190-220A After each smelting is completed, wait for the ingot to cool to room temperature, and then perform the next smelting to obtain a zirconium-titanium-nickel alloy ingot with uniform composition. The smelted alloy ingot is cooled in the smelting furnace for 10 minutes and then taken out. Such as figure 1 As shown, it can be known that the phase composition of the prepared zirconium-titanium-nickel alloy is α phase and trace amount of C14 phase. Such as figure 2 As shown, it can be seen that the microstructure of the prepared zirconium-titanium-nickel alloy is composed of flaky α phase. Such as Figure 5 It shows that the prepared zirconium-titanium-nickel alloy has good fracture strength and high ...

Embodiment 2

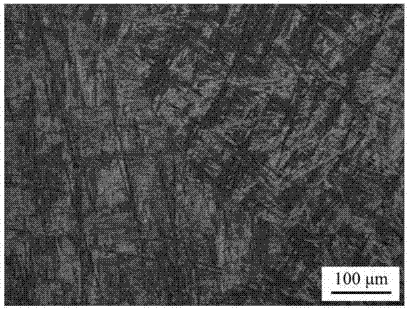

[0020] Take 29.1g of pure zirconium wire, 29.1g of pure titanium wire, and 1.8g of pure nickel wire, and place them in a non-consumable vacuum arc melting furnace for repeated melting for 6 times, each melting time is 3 minutes, and the melting electrode current is kept at 190-220A After each smelting is completed, wait for the ingot to cool to room temperature, and then perform the next smelting to obtain a zirconium-titanium-nickel alloy ingot with uniform composition. The smelted alloy ingot is cooled in the smelting furnace for 10 minutes and then taken out. Such as figure 1 As shown, it can be known that the prepared zirconium-titanium-nickel alloy contains α phase and trace amount of C14 phase. Such as image 3 As shown, it can be seen that the microstructure of the alloy is composed of flaky α-phase, but the width of the α-sheet layer is reduced compared with the zirconium-titanium-nickel alloy prepared in Example 1, indicating that the increase of nickel will make th...

Embodiment 3

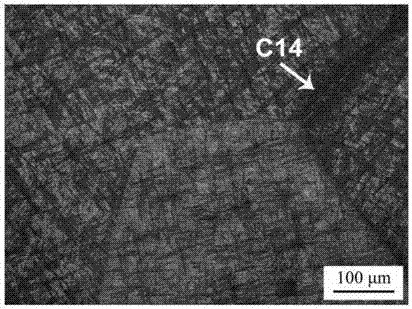

[0023] Take 28.5g of pure zirconium wire, 28.5g of pure titanium wire, and 3g of pure nickel wire, and place them in a non-consumable vacuum arc melting furnace for repeated melting 6 times, each melting time is 3 minutes, and the melting electrode current is kept at 190-220A. After each smelting is completed, wait for the ingot to cool down to room temperature, and then perform the next smelting to obtain a zirconium-titanium-nickel alloy ingot with uniform composition. The smelted alloy ingot is cooled in the smelting furnace for 10 minutes and then taken out. Such as figure 1 As shown, it shows that with the increase of nickel content, the content of C14 phase in the alloy increases. The prepared zirconium-titanium-nickel alloy consists of two phases: α phase and C14 phase. Such as Figure 4 As shown, it shows that the metallographic microstructure of the prepared zirconium-titanium-nickel alloy is composed of flaky α phase and C14 compound. Such as Figure 5 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com