Heat treatment method of magnesium-containing cast aluminum lithium alloy

A heat treatment method and technology for casting aluminum, applied in the field of aluminum alloy heat treatment, can solve the problems of difficult heat treatment and low plasticity, and achieve the effect of solving the problem of grain size growth, improving elongation, and solving low plasticity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

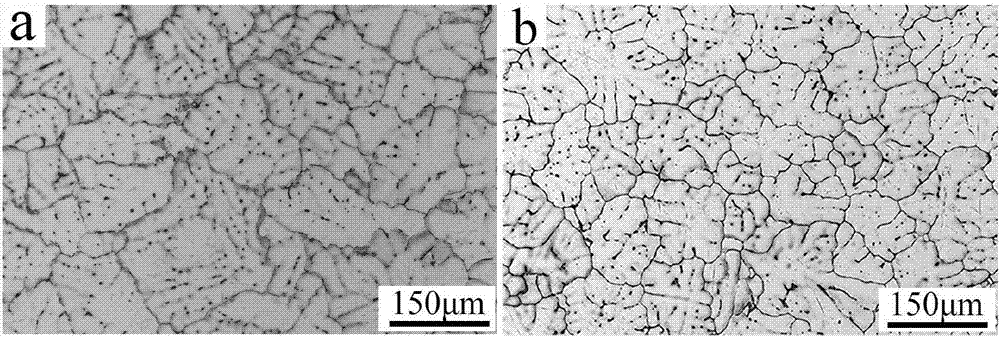

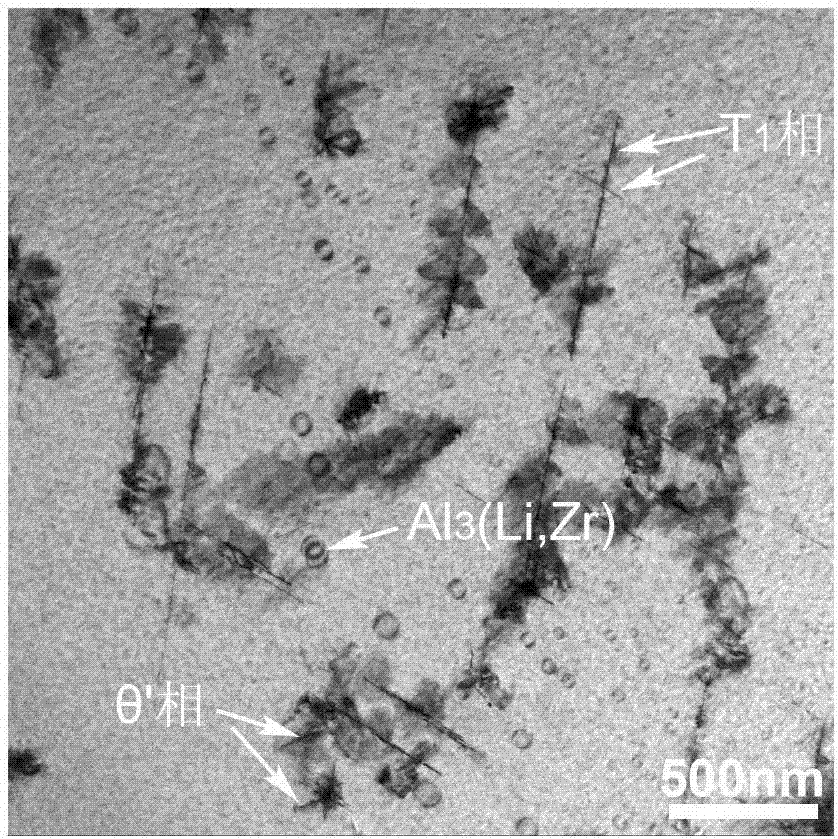

[0036] The magnesium-containing cast aluminum-lithium alloy used in this example is self-smelted and obtained by gravity casting of a metal mold. The nominal chemical composition is: Li 2.0%, Cu 2.0%, Zr 0.20%, 0.4% Mg, and the rest is Al, denoted as alloy B, in order to show the beneficial effect of Mg element in casting aluminum-lithium alloy, the same process was used to smelt aluminum-lithium alloy without magnesium as a comparison group, denoted as alloy A, the actual composition of alloy A and alloy B As shown in Table 1. The as-cast structure is composed of dendrites, and the continuous second phase is enriched on the grain boundaries. figure 1 Among them, a and b are metallographic photographs of the as-cast structure of alloy A and alloy B in this embodiment respectively, and through XRD and EDS analysis, the second phase is mainly composed of Al 2 Cu、Al 2 CuLi and Al 3 Composition of Li, there is also a small amount of Al in magnesium-containing alloys 2 CuMg pha...

Embodiment 2

[0055] The magnesium-containing cast aluminum-lithium alloy used in this example is self-smelted and obtained by gravity casting of a metal mold. The nominal chemical composition is: Li 2.0%, Cu 2.0%, Zr 0.20%, 2.5% Mg, and the rest is Al. When a higher content of Mg is added, the as-cast structure of the alloy is composed of dendrites, more continuous second phases are enriched on the grain boundaries, and the grains are slightly refined compared with the control group without adding Mg. The reason is that the supercooling of the components caused by the segregation of Mg elements has a certain refining effect on the as-cast structure, such as Figure 5 As shown, the as-cast alloy containing 2.5Mg has a certain degree of grain refinement than the as-cast alloy without Mg (0Mg). According to XRD and EDS analysis, the second phase enriched near the grain boundary is mainly Al 2 Cu、Al 2 CuLi, Al 3 Li and Al 2 CuMg phase. The tensile strength of the alloy containing 2.5Mg i...

Embodiment 3

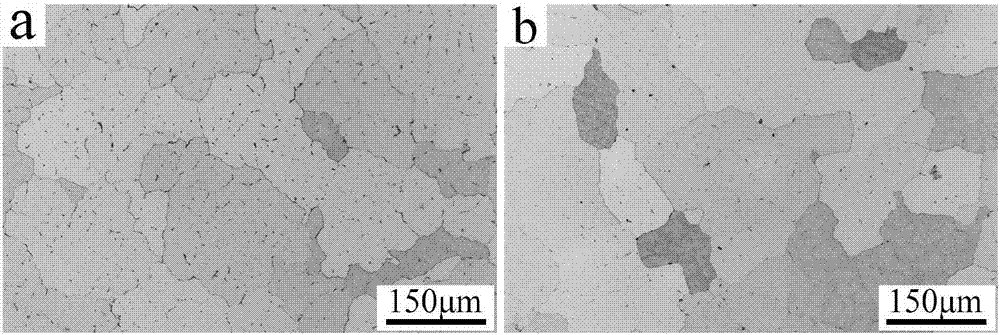

[0068]The magnesium-containing cast aluminum-lithium alloy used in this example is self-smelted and obtained by gravity casting of a metal mold. The nominal chemical composition is: Li 2.0%, Cu 2.0%, Zr 0.20%, 1.0% Mg, 0.11% by mass percentage Sc, the rest is Al. Sc element is a very effective refiner in Al alloy. Compared with alloy B in Example 1, the grain size is greatly reduced, and the comparison with the grain size before adding Sc is as Image 6 As shown in a and 6b, the as-cast structure transforms from dendrites to fine equiaxed grains. The continuous network non-equilibrium second phase is still enriched near the grain boundary. Significantly refined grains will not only increase the strength of the alloy, but also further improve the plasticity.

[0069] The magnesium-containing cast aluminum-lithium alloy prepared in this example was used for heat treatment, and only the time of the first-stage solid solution treatment was controlled to obtain 3 samples. Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com