Imbricate solar photovoltaic module and protection equipment thereof

A solar photovoltaic and production equipment technology, applied in the field of solar cells, can solve the problems of increased material cost and process complexity of insulating pads, large heat generation of bypass leads, and impact on the long-term reliability of photovoltaic modules, etc., to improve the utilization rate of light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

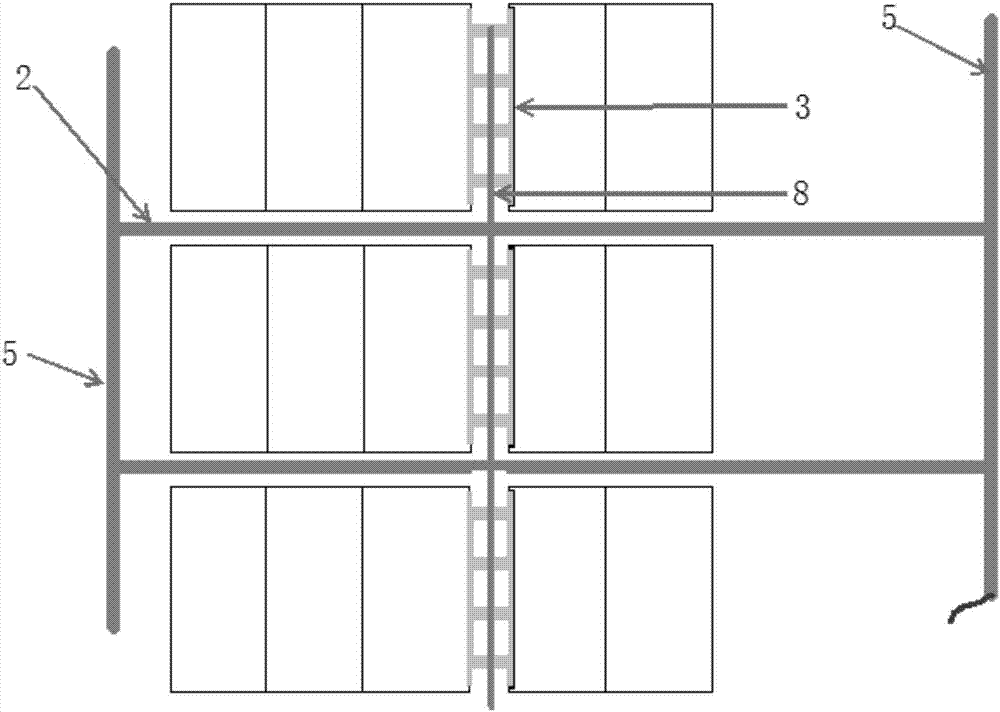

[0041] The invention provides a pattern design solution that can be used for laminated photovoltaic modules, half-slice battery modules, 1 / 3 slice battery modules, and full-sheet battery modules, and can be used for double-sided laminated modules. The solar battery sheet can be a double-sided battery sheet that can absorb light to generate electricity on both the front and back sides.

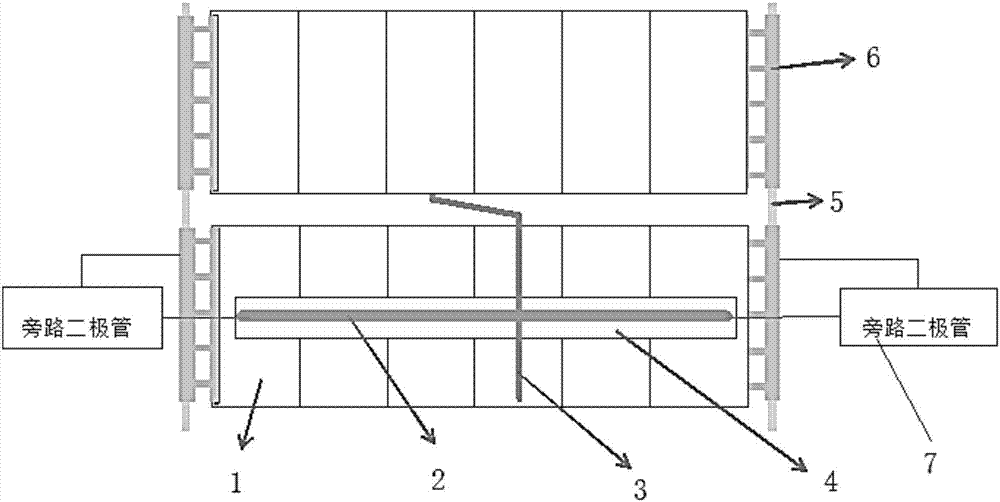

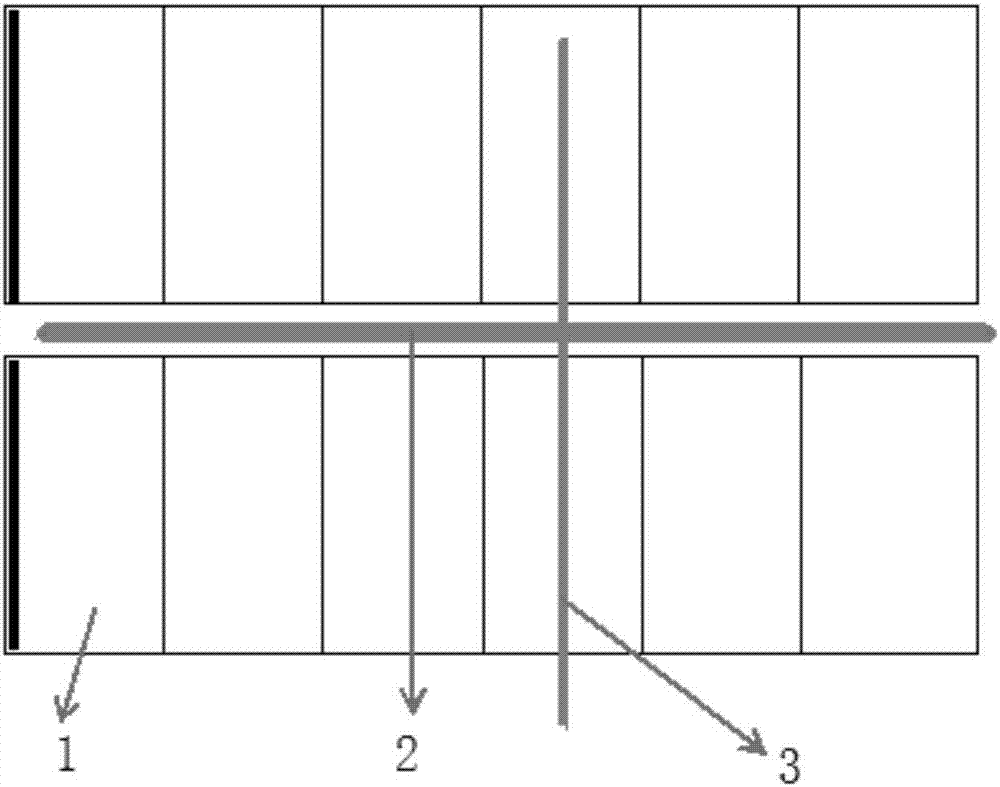

[0042] A shingled solar photovoltaic module, which contains one or more solar cell strings, and each solar cell string is composed of two or more solar cell sheets. Adjacent sides of two adjacent solar battery sheets in the same solar battery string overlap with each other, and the overlapping width is 0.2 to 2.5 millimeters.

[0043] The overlapping area uses conductive material A, such as conductive glue, to form a conductive connection between the two battery she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com