A damage control method for ultra-precision turning of crystal materials

A technology of crystal materials and control methods, applied in stone processing equipment, crystal growth, chemical instruments and methods, etc., can solve the problems of damage, large consumption of irradiated ions, high manufacturing cost, etc., achieve a large number and reduce irradiation Dosage and processing cost, effect of reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

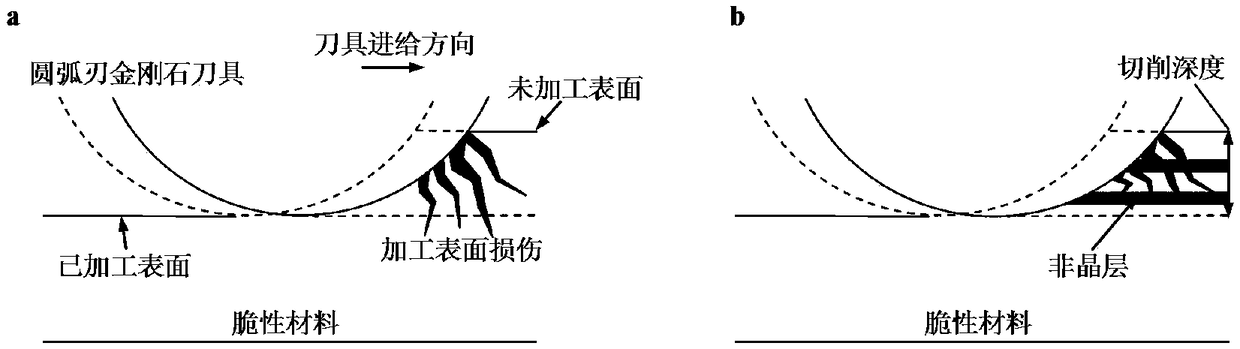

Problems solved by technology

Method used

Image

Examples

Embodiment

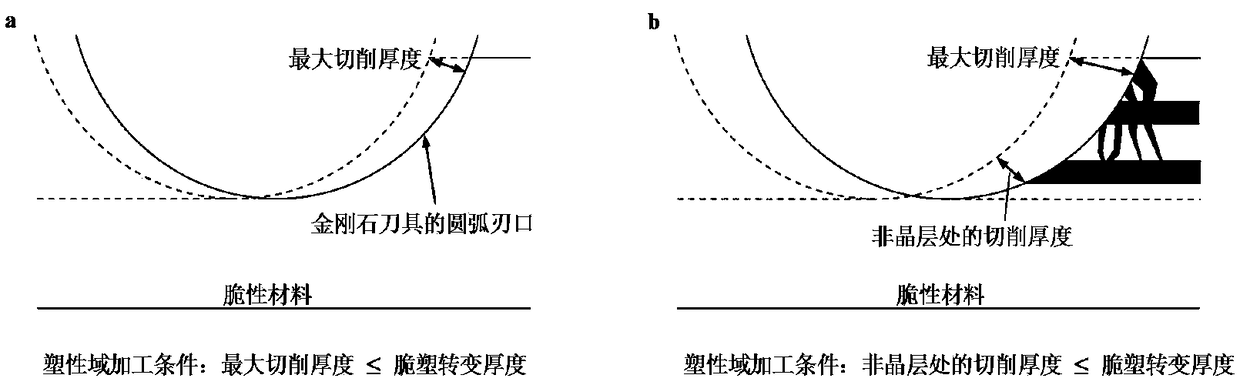

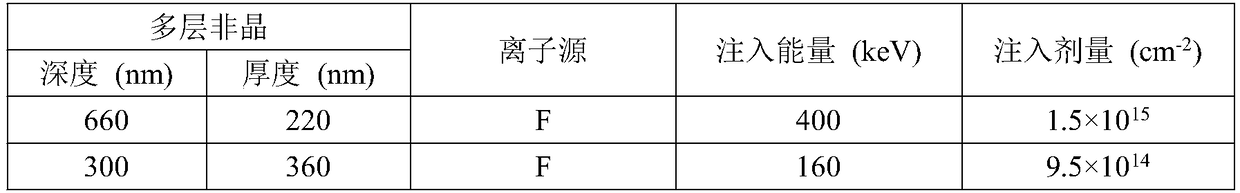

[0023] 1. Design a multi-layer amorphous system according to the material to be processed and cutting parameters, determine the number, depth and thickness of the amorphous layer, and use the Monte Carlo (realized by SRIM software) numerical method to simulate the ion irradiation process and calculate the ion source , the combination of injection energy and dose parameters.

[0024] 2. According to the calculated implantation parameters, commercial ion implanters or high-energy accelerators are used to irradiate ions to complete the preparation of multi-layer amorphous structures inside the material;

[0025] 3. Combining the tool arc radius, cutting depth, geometric parameters of the amorphous layer and the brittle-plastic transition thickness of the workpiece material, determine the maximum feed rate allowed for turning;

[0026] 4. According to the above-mentioned turning parameters, carry out plane machining experiments on modified crystals and ordinary crystals.

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com