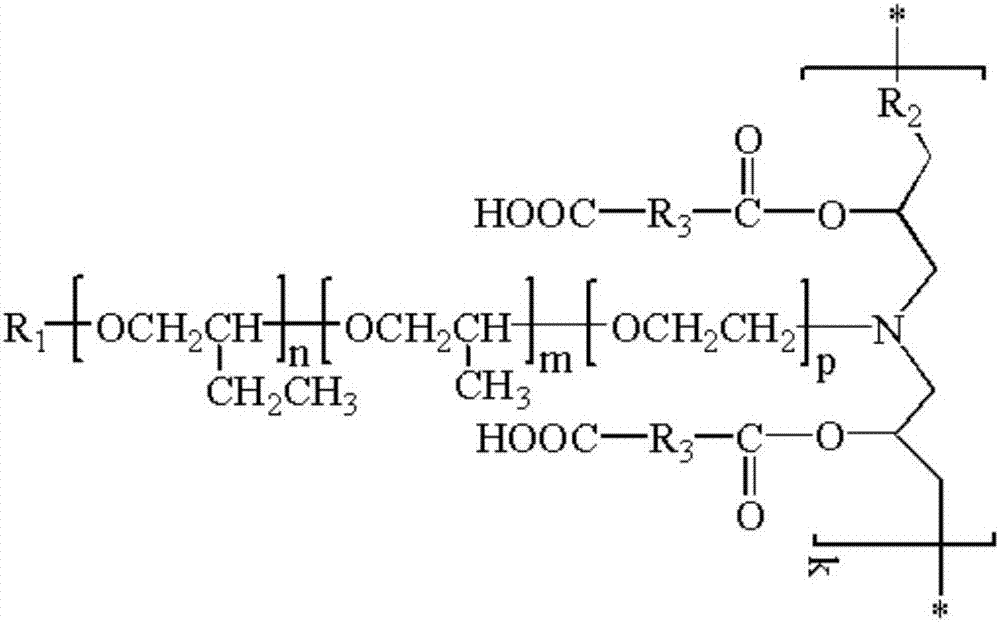

Polyether amine water reducing agent with controllable and regular molecular structure and preparation method of polyether amine water reducing agent

A technology of polyether amines and molecular structure, which is applied in the field of preparing polywater reducers by combining amine-epoxy ring-opening polymerization and esterification, which can solve the problem of large steric hindrance of unsaturated macromonomers Problems such as the inability of the initiator to initiate and the failure of the macromolecular initiator to achieve rapid and high-efficiency response, good cost performance and competitive advantage, and reduce the difficulty of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

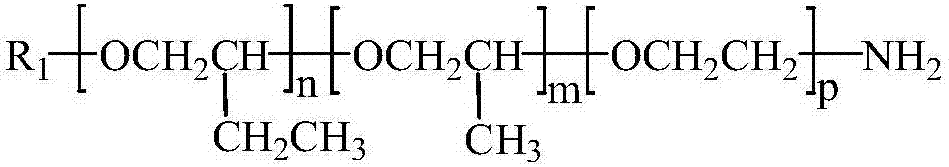

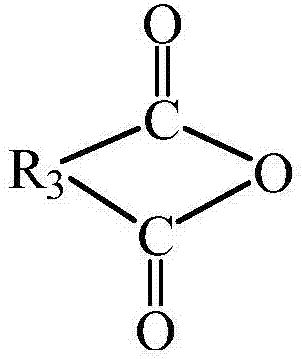

[0044] 10mol amino-terminated polyether (R 1is methyl, m and n are both zero, p=10, and the weight average molecular weight is 500), 11mol 1,3-butadiene diepoxide is stirred at normal temperature and pressure for 5h to carry out amino-epoxy ring-opening polymerization reaction to realize the grafting of amino-terminated polyether on the main chain into a side chain polymer. After the reaction is completed, after dehydration and drying, add dehydrated dimethyl sulfoxide, then add 22mol malonic anhydride and 0.1mol dimethyl The aminopyridine was subjected to an esterification reaction for 0.5 h to obtain a polyether amine water reducer with a weight average molecular weight of 20,000.

Embodiment 2

[0046] 10mol amino-terminated polyether (R 1 is methyl, m and n are both zero, p=17, and the weight average molecular weight is 800), 10.1mol1,5-hexadiene diepoxide is stirred at normal temperature and pressure for 1h to carry out amino-epoxy ring-opening polymerization Reaction, to realize the grafting of amino-terminated polyether on the main chain into a side chain polymer, after the reaction is completed, after dehydration and drying, add dehydrated tetrahydrofuran, then add 20.1mol malonic anhydride and 0.2mol p-toluenesulfonic acid for esterification The reaction was carried out for 1 hour to obtain a polyetheramine water reducer with a weight average molecular weight of 40,000.

Embodiment 3

[0048] 10mol amino-terminated polyether (R 1 is methyl, m is zero, n=7, p=10, weight average molecular weight is 1000), 10.2mol bis(2,3-epoxycyclopentyl)ether is stirred at normal temperature and pressure for 5h to carry out amino- Epoxy ring-opening polymerization reaction, to realize the grafting of amino-terminated polyether on the main chain to form a side chain polymer. After the reaction is completed, after dehydration and drying, add dehydrated N,N dimethylformamide, and then add 21.1mol Succinic anhydride and 0.3 mol of strongly acidic cation exchange resin were esterified for 1 hour to obtain a polyether amine water reducer with a weight average molecular weight of 50,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com