Grafted modified radiation crosslinked polyethylene heat resistant pipe and preparation method thereof

A cross-linked polyethylene and graft-modified technology, which is applied in the field of graft-modified radiation cross-linked polyethylene heat-resistant pipes and their preparation, can solve problems such as the breakdown radiation dose of pipes, and achieve the elimination of local breakdown. , The effect of reducing the radiation dose and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a graft-modified radiation cross-linked polyethylene heat-resistant pipe of the present invention comprises the following steps:

[0026] Step 1, using a cobalt source or an electron accelerator to pre-irradiate the high-density polyethylene with an irradiation dose of 0.1-1 Mrad to obtain pre-irradiated high-density polyethylene;

[0027] Step 2, according to the mass ratio is (40-80): (1-4), preferably (70-80): (3-4), the pre-irradiated high-density polyethylene obtained in step 1 and triallyl Isocyanurate is physically mixed, mixed evenly and added to the twin-screw extruder, after pulling out, cooling, and pelletizing, high-density polyethylene grafts are obtained, and the extrusion temperature is 180-220°C;

[0028] Step 3, according to the mass ratio is (50-100): (15-55): (2-6), preferably (80-100): (35-55): (5-6), high density polyethylene, The high-density polyethylene graft obtained in step 2 is physically mixed with the antioxidant B21...

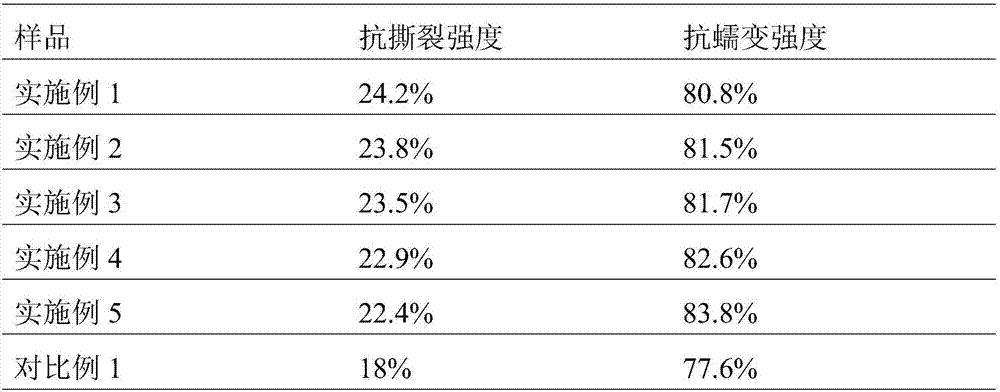

Embodiment 1

[0033] Step 1, using an electron accelerator to pre-irradiate the high-density polyethylene with an irradiation dose of 0.4 Mrad to obtain pre-irradiated high-density polyethylene;

[0034] Step 2. According to the mass ratio of 40:1, after the pre-irradiated high-density polyethylene obtained in step 1 and TAIC are physically mixed evenly, they are added to a twin-screw extruder, and after pulling out, cooling, and pelletizing, the obtained High-density polyethylene grafts;

[0035] Step 3: Physically mix high-density polyethylene, high-density polyethylene branches obtained in step 2, and antioxidant B215 according to a mass ratio of 50:15:2, and then add a high-speed extruder to extrude at 180-220°C Pipe material, obtains the polyethylene pipe material of graft modification;

[0036] Step 4: Using an electron accelerator to irradiate the grafted modified polyethylene pipe obtained in Step 3 at a dose of 9 Mrad to obtain a graft modified radiation crosslinked polyethylene h...

Embodiment 2

[0038] Step 1, using a cobalt source to pre-irradiate the high-density polyethylene, and the irradiation measurement is 0.6 Mrad to obtain pre-irradiated high-density polyethylene;

[0039] Step 2. According to the mass ratio of 50:2, after the pre-irradiated high-density polyethylene obtained in step 1 and TAIC are physically mixed evenly, they are added to a twin-screw extruder, and after pulling out, cooling, and pelletizing, the obtained High-density polyethylene grafts;

[0040] Step 3: According to the mass ratio of 60:20:3, HDPE, the high-density polyethylene graft obtained in Step 2, and antioxidant B215 are physically mixed evenly, and then added to a high-speed extruder to extrude at 180-220°C The pipe is discharged to obtain a graft-modified polyethylene pipe;

[0041] Step 4: Using an electron accelerator to irradiate the grafted modified polyethylene pipe obtained in Step 3 at a dose of 8.5 Mrad to obtain a graft modified radiation crosslinked polyethylene heat-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com