An oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced resin-based structural wave-absorbing material and its preparation method

A silicon carbide fiber and resin-reinforced technology, which is applied in the field of wave-absorbing materials, can solve problems such as high density, poor mechanical properties, and complex molding processes, and achieve the effects of improving electrical conductivity, good mechanical properties, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced resin-based structure wave-absorbing material of the present invention comprises the following process steps:

[0034] Step 1. The degumming process of silicon carbide fiber cloth.

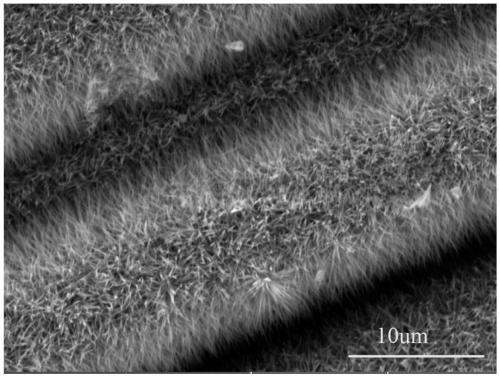

[0035] Step 2. Preparation of oxide nanowire-silicon carbide fiber multi-scale reinforcement.

[0036] Step 3, preparation of oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced resin-based structural wave-absorbing material.

[0037] Wherein, when the resin matrix used is epoxy resin or silicone resin, the molding process of the resin-based structural wave-absorbing material of the present invention is a hand lay-up molding process; when the resin matrix used is polyimide resin, polybenzoxazole resin , The molding process of the resin-based structural wave-absorbing material of the present invention is a molding process.

[0038] The invention provides an oxide na...

Embodiment 1

[0040] This embodiment is a zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced resin-based structure wave-absorbing material and its preparation method. The zinc oxide nanowire-silicon carbide fiber multiscale reinforcement resin-based structure wave-absorbing material uses epoxy resin as a matrix, and the zinc oxide nanowire-silicon carbide fiber multiscale reinforcement as a reinforcement. In this embodiment, the content of the zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement is 40 wt%, and the content of the epoxy resin matrix is 60 wt%.

[0041] This example also proposes a method for preparing the zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced epoxy resin-based structural wave-absorbing material, the specific process is:

[0042] Step 1. Silicon carbide fiber cloth to remove glue. Cut the silicon carbide fiber cloth into 6 pieces, and the size of each piece is 45mm*45mm. Put the cut silicon...

Embodiment 2

[0046] This embodiment is a zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced resin-based structure wave-absorbing material and its preparation method. The zinc oxide nanowire-silicon carbide fiber multiscale reinforcement resin-based structure wave-absorbing material uses epoxy resin as a matrix, and the zinc oxide nanowire-silicon carbide fiber multiscale reinforcement as a reinforcement. In this embodiment, the content of the zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement is 50 wt%, and the content of the epoxy resin matrix is 50 wt%.

[0047] This example also proposes a method for preparing the zinc oxide nanowire-silicon carbide fiber multi-scale reinforcement reinforced epoxy resin-based structural wave-absorbing material, the specific process is:

[0048] Step 1. Silicon carbide fiber cloth to remove glue. Cut the silicon carbide fiber cloth into 6 pieces, and the size of each piece is 45mm*45mm. Put the cut silicon...

PUM

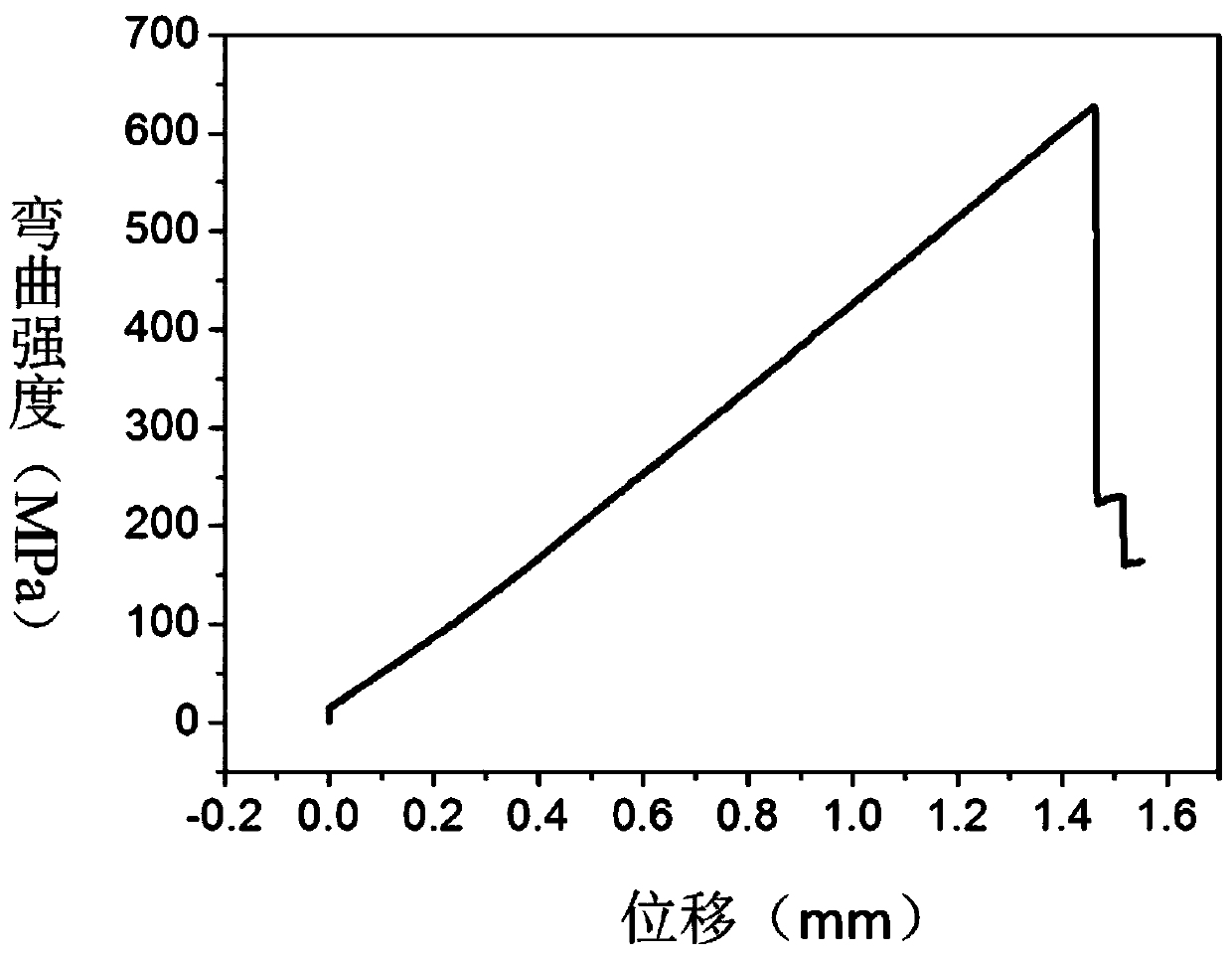

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com