A novel timber material

A new type of wood technology, applied in the field of wood, can solve the problems of less research and application of glass fiber, and achieve the effects of simple structure, improved static bending strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

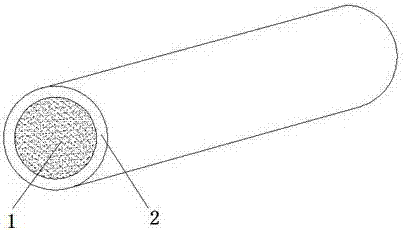

[0053] A new type of wood material is formed by bonding a composite core board 1 and a reinforced board 2. The raw materials of the composite core board 1 and the parts by weight of each raw material are:

[0054] Mixed wood flour: 27 parts;

[0055] Wood fiber powder: 20 parts;

[0056] Alkali-free chopped glass fiber: 15 parts;

[0057] High-density polyethylene: 6 parts;

[0058] 12 parts of polybenzobisoxazole fiber;

[0059] Basalt fiber: 20 parts;

[0060] Mannitol: 19 parts;

[0061] 10 parts of silane coupling agent;

[0062] The mixed wood flour is the powder obtained by grinding poplar, eucalyptus, and elm leftovers when making products, and mixed according to m poplar powder: m eucalyptus powder: m elm powder = 1:2:2 , the particle size is 130 microns;

[0063] The particle size of the basalt fiber is 135 microns;

[0064] The polybenzobisoxazole fibers are powder particles with a particle size of 600um.

[0065] Further, the non-alkali chopped glass fiber ...

Embodiment 2

[0074] A new type of wood material is formed by bonding a composite core board 1 and a reinforced board 2. The raw materials of the composite core board 1 and the parts by weight of each raw material are:

[0075] Mixed wood flour: 22 parts;

[0076] Wood fiber powder: 29 parts;

[0077] Alkali-free chopped glass fiber: 11 parts;

[0078] High-density polyethylene: 9 parts;

[0079] 9 parts of polybenzobisoxazole fiber;

[0080] Basalt Fiber: 16 parts;

[0081] Mannitol: 21 parts;

[0082] 7 parts of silane coupling agent;

[0083] The mixed wood flour is the powder obtained by grinding poplar, eucalyptus, and elm leftovers when making products, and mixed according to m poplar powder: m eucalyptus powder: m elm powder = 1:2:2 , the particle size is 150 microns;

[0084] The particle size of the basalt fiber is 160 microns;

[0085] The polybenzobisoxazole fibers are powder particles with a particle size of 750um.

[0086] Further, the non-alkali chopped glass fiber ha...

Embodiment 3

[0091] A new type of wood material is formed by bonding a composite core board 1 and a reinforced board 2. The raw materials of the composite core board 1 and the parts by weight of each raw material are:

[0092] Mixed wood flour: 34 parts;

[0093] Wood fiber powder: 16 parts;

[0094] Alkali-free chopped glass fiber: 19 parts;

[0095] High-density polyethylene: 4 parts;

[0096] 16 parts of polybenzobisoxazole fiber;

[0097] Basalt Fiber: 16 parts;

[0098] Mannitol: 21 parts;

[0099] 7 parts of silane coupling agent;

[0100] The mixed wood flour is the powder obtained by grinding poplar, eucalyptus, and elm leftovers when making products, and mixed according to m poplar powder: m eucalyptus powder: m elm powder = 1:2:2 , the particle size is 100 microns;

[0101] The particle size of the basalt fiber is 120 microns;

[0102] The polybenzobisoxazole fibers are powder particles with a particle size of 500um.

[0103] Further, the length of the non-alkali chopped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com