Environment-friendly utilization process of volatile organic compounds in rare earth smelting

A technology of volatile organic compounds and organic compounds, applied in the field of environmental protection utilization technology, can solve problems such as human side effects, surrounding environmental pollution, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

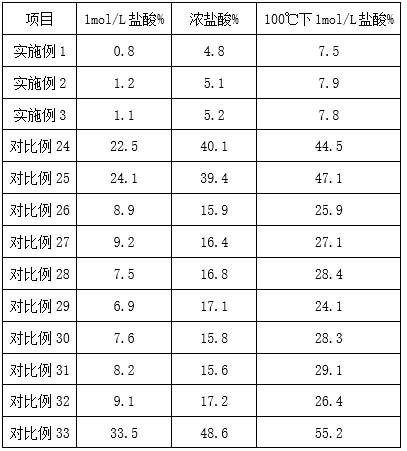

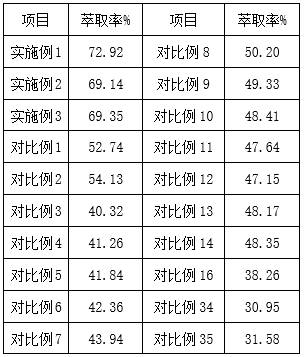

Examples

Embodiment 1

[0046] An environment-friendly utilization process of volatile organic compounds in rare earth smelting.

[0047] The preparation method of organic matter α is:

[0048] 1) Sulfonated P50725 parts, P20428 parts, N23528 parts, and 4 parts of additives are mixed at 45°C and set aside;

[0049] 2) Mix 0.05mol / L hydrochloric acid solution and ethanol solution at a volume ratio of 1:1, and set aside;

[0050] 3) Mix the mixed solution of the above step 1) and step 2) according to the volume ratio of 3:1 and mix it evenly.

[0051] Wherein, the preparation method of sulfonated P507 is:

[0052] Take 18 parts of P5071 into a reaction kettle, add 23 parts of oleum to it, raise the temperature to 130°C, pressurize at 1.2MPa, and keep the temperature for 4.5 hours to obtain the product.

[0053] The preparation method of additive is:

[0054] 1) Put 5 parts of acetylacetone and 6 parts of (3,3-diethoxypropyl) diethyl phosphate into the reactor, add ethanol solution, heat up to 128°C...

Embodiment 2

[0083] An environment-friendly utilization process of volatile organic compounds in rare earth smelting.

[0084] The preparation method of organic matter α is:

[0085] 1) Sulfonate 20 parts of P50720 parts, 30 parts of P20430 parts, 5 parts of N23525 parts, and 5 parts of additives, and make a mixed solution at 45 °C, which is the mixed solution a;

[0086] 2) Make a mixed solution of 0.05mol / L hydrochloric acid solution and ethanol solution according to the volume ratio of 1:1, which is the mixed solution b;

[0087] 3) Mix the mixed solution of the above step 1) and step 2) according to the volume ratio of 3:1 and mix it evenly.

[0088] Wherein, the preparation method of sulfonated P507 is:

[0089] Take 20 parts of P507 and put it into a reaction kettle, add 20 parts of oleum to it, raise the temperature to 130°C, press at 1.2MPa, and keep it warm for 5 hours to obtain the product.

[0090] The preparation method of additive is:

[0091] 1) Put 6 parts of acetylaceto...

Embodiment 3

[0120] An environment-friendly utilization process of volatile organic compounds in rare earth smelting.

[0121] The preparation method of organic matter α is:

[0122] 1) Sulfonate P50730 parts, P20425 parts, N23530 parts, and 3 parts of additives, and make a mixed solution at 45°C, which is mixed solution a;

[0123] 2) Make a mixed solution of 0.05mol / L hydrochloric acid solution and ethanol solution according to the volume ratio of 1:1, which is the mixed solution b;

[0124] 3) Mix the mixed solution of the above step 1) and step 2) according to the volume ratio of 3:1 and mix it evenly.

[0125] Wherein, the preparation method of sulfonated P507 is:

[0126] Take 15 parts of P5071 and put it into a reaction kettle, add 25 parts of oleum to it, raise the temperature to 130°C, press at 1.2MPa, and keep it warm for 4 hours to obtain the product.

[0127] The preparation method of additive is:

[0128] 1) Put 4 parts of acetylacetone and 7 parts of (3,3-diethoxypropyl) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com