Genetically engineered bacterium for expressing heat resistant type dextransucrase, as well as construction method and application of genetically engineered bacterium

A technology of dextran sucrose and genetically engineered bacteria, applied in genetic engineering, microbe-based methods, plant genetic improvement, etc., can solve problems such as reaction rate and process temperature influence, and achieve the effect of saving production capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Construction of recombinant expression plasmid pET28a(+) / dex-YG

[0040] According to the dextran sucrase gene (dexYG) sequence obtained by cloning, according to the sequence characteristics of the expression vector pET28a (+), the primers were designed as follows by means of Primer Premier 5.0 software:

[0041] Forward primer: 5'CGC GGATCC ATGCCATTTACAGAAAAAGT 3', (contains a BamHI site);

[0042] Reverse primer: 5'CCC AAGCTT TTATGCTGACACAGCATTT3', (contains a HindIII site).

[0043] Using the cloned dextran sucrase gene (dexYG) as a template, PCR amplification technology was used to obtain gene clone products containing BamHI and HindIII restriction sites. The PCR product recovery procedure is as follows:

[0044] 1. Cut out the target DNA band in the agarose gel, put it into a clean centrifuge tube and weigh it. If the gel weighs 100mg, it can be regarded as 100μL (100mg≈100μL).

[0045] 2. Add three times the volume of solution GSB, melt the glue in...

Embodiment 2

[0052] Example 2: Construction of genetically engineered bacteria dex-YG-thMU01 expressing thermostable dextran sucrase

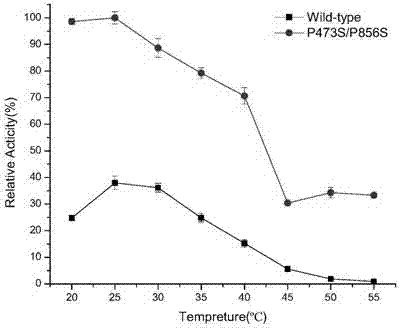

[0053] The recombinant expression plasmid pET28a(+) / dex-YG was transformed into E.coli BL21(DE3) competent cells, and after kanamycin resistance screening and enzyme digestion verification, the dextran sucrase engineered strain E. Coli BL21(DE3) / pET28a(+) / dex-YG. Extract its plasmid as a template, and perform site-directed mutation on the recombinant plasmid. First, mutate proline at position 473 to serine to obtain a single mutant P473S, extract its plasmid as a template, and then mutate proline at position 856 to serine , obtained the double mutant P473S / P856S, transformed it into E.coli BL21 (DE3) competent cells, and obtained the genetically engineered strain dex -YG-thMU01, the primers for the double mutant were designed as follows:

[0054] P473S forward primer: 5'AACAGTCCACTGACA T CTGATGCTA 3';

[0055] P473S reverse primer: 5' A TGTCAGTGGACTGTT...

Embodiment 3

[0069] Example 3: Expression of heat-resistant recombinant engineered bacteria dex-YG-thMU01 dextran sucrase

[0070] The recombinant engineered strain dex-YG-thMU01 was inoculated into liquid LB medium containing 50 μg / mL kanamycin and cultured at 37°C for 16-18 hours, then transferred to liquid A medium and cultured at 37°C, when diluted 10 OD after times 600 When it reached 0.25, 1 mmol / mL IPTG was added for induction, and samples were taken every 1 hour for a total of 5 times, and the samples were analyzed by SDS-PAGE electrophoresis. Among them, the amount of enzyme was more in the 4th to 5th hour, and the molecular weight of the expressed dextrose-sucrase protein was consistent with the predicted value (about 170kDa).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com