Floor slab waterproof structure

A technology for structures and foundations, which can be applied to cohesive pavements, roads, bridges and other directions paved on site. It can solve problems such as delay in construction period, slow drying, and poor adhesion between layers, so as to shorten construction time and improve adhesion. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

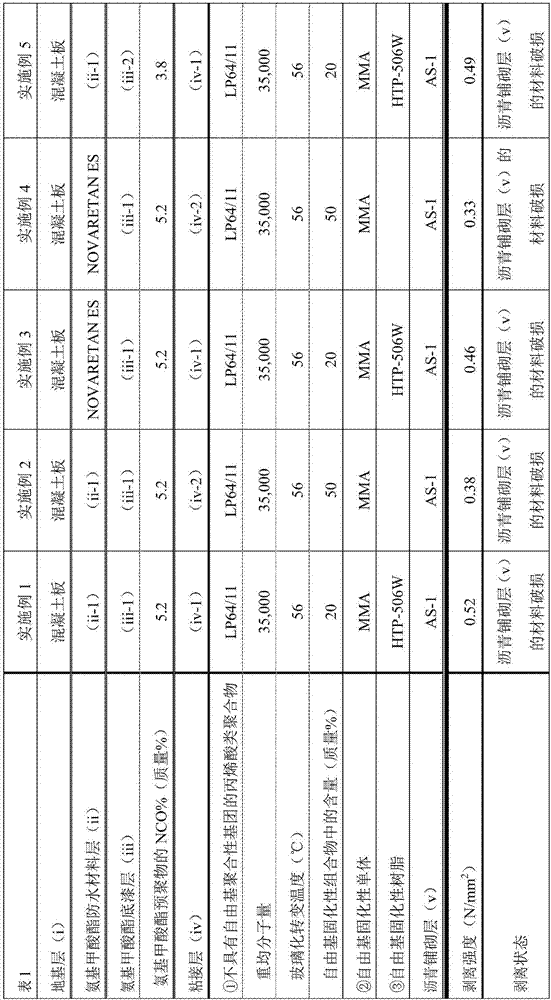

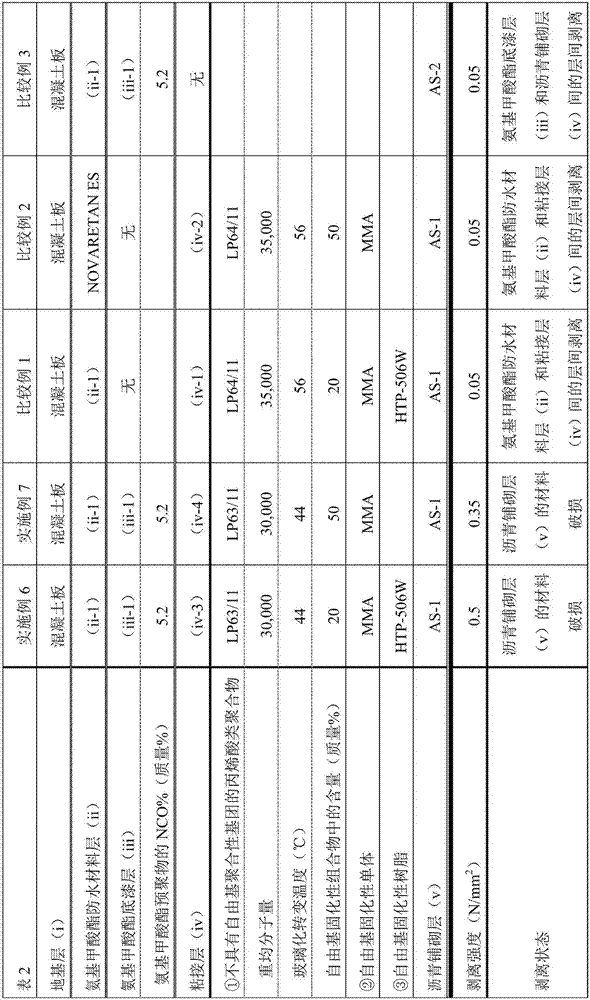

[0089] Hereinafter, the present invention will be described in more detail using examples.

Synthetic example 1

[0090] [Synthesis Example 1] Preparation of Moisture Curable Urethane Composition (ii-1) for Urethane Waterproofing Material

[0091] In a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, 1,000 parts by mass of polytetramethylene glycol (number average molecular weight: 1,000) and 297 parts by mass of dipropylene glycol were mixed, and 661 parts by mass of toluene diisocyanate was added thereto, and reacted at 90° C. for 8 hours under a nitrogen stream to obtain a urethane prepolymer having an NCO% of 2.5 mass % and a weight average molecular weight of 6,080.

[0092] Next, 100 parts by mass of polyoxyethylene polyoxypropylene diol (number average molecular weight: 1,000, content of oxyethylene structure: 20 mass %) and 80 parts by mass of toluene diisocyanate were reacted to obtain NCO% of 16.8 mass % Urethane prepolymer. Next, 40 parts by mass of xylene was added, and 114.5 parts by mass of N-2-isopropyl-3-(2-hydroxyethyl...

Synthetic example 2

[0095] [Synthesis Example 2] Preparation of Moisture Curing Type Urethane Primer (iii-1)

[0096] In a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, 300 parts by mass of crude MDI ("Millionate MR-200" manufactured by Nippon Polyurethane Industry Co., Ltd.), polypropylene glycol (number average molecular weight: 700) 210 parts by mass, 474 parts by mass of toluene, and 474 parts by mass of ethyl acetate were reacted at 80°C for 5 hours to obtain a moisture-curable urethane having a solid content of 35% by mass and an NCO% of 5.2% by mass Primer (iii-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com