Method for preparing hydroxytyrosol by combining enzymatic catalysis and high-temperature hydrolysis

A technology of hydroxytyrosol and high-temperature hydrolysis, which is applied in the fields of biochemistry and medical and health care products, can solve the problems of high corrosion, high synthesis cost, and troublesome neutralization, and achieves the effects of cost saving and yield improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

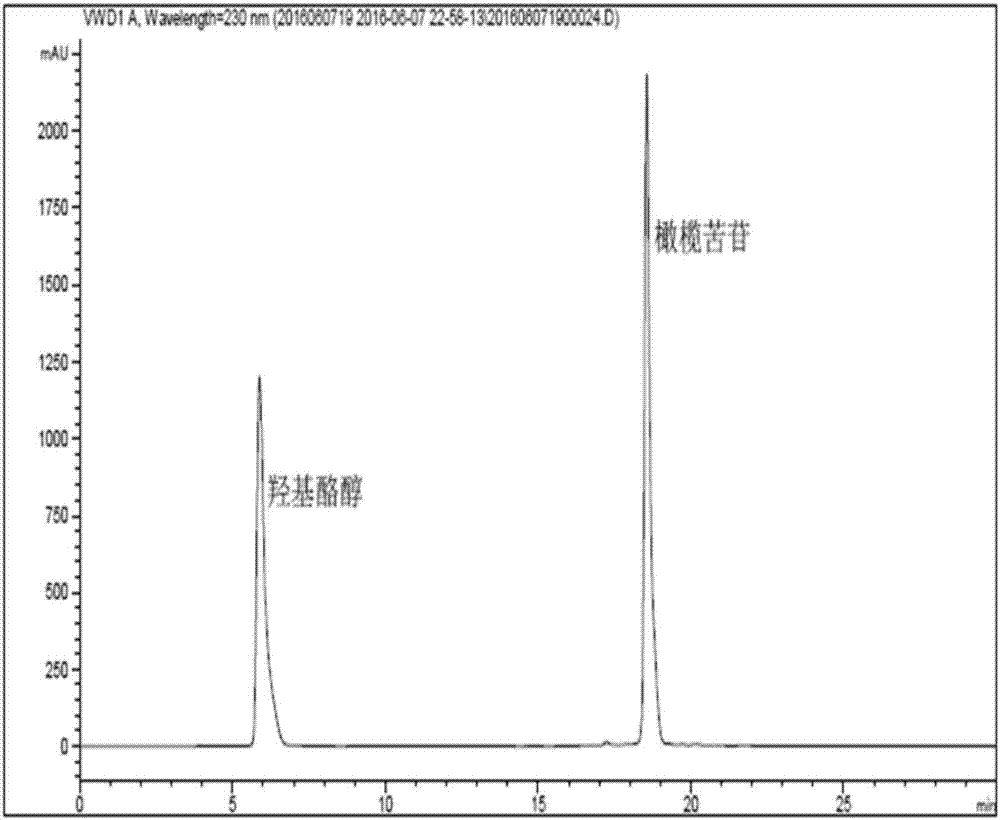

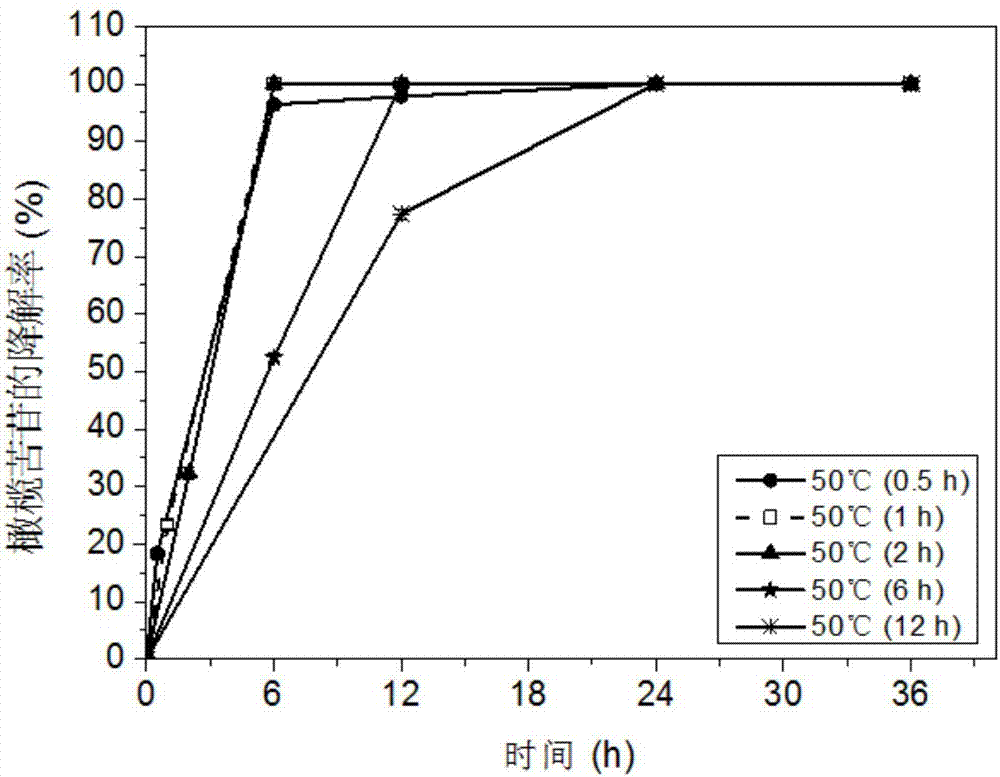

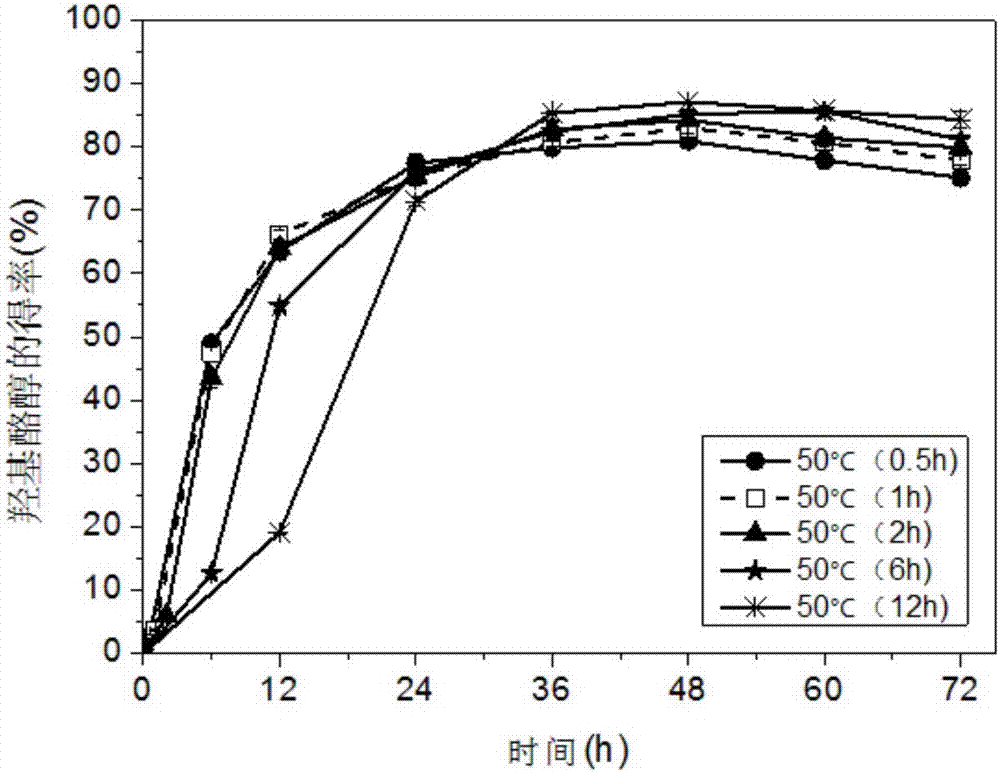

Embodiment 1

[0029] Get concentration and be that 50mL of oleuropein solution of 10.0g / L is placed in the Erlenmeyer flask of 125mL, add the cellulase (Novozyme, β-glucosidase) that is rich in high activity β-glucosidase of 10FPU / g oleuropein The ratio of enzyme activity to filter paper enzyme activity is not less than 25), enzymolysis at 50°C for 12h, then raise the temperature to 90°C, and continue hydrolysis for 36h. After the enzymolysis, the enzymolysis solution was centrifuged at 8000r / min for 10min. After centrifugation, the filtrate was passed through a 0.22 μm filter membrane, and after dilution, HPLC detection and analysis showed that the degradation rate of oleuropein was 100%, and the yield of hydroxytyrosol was 88.90% (the content was equivalent to 2.53g / L).

Embodiment 2

[0031]Measure the oleuropein solution 50mL that concentration is 12.5g / L and place in the conical flask of 125mL, add the cellulase (Novozyme, β-glucosidase that is rich in the high activity β-glucosidase of 60FPU / g oleuropein The ratio of glucosidase activity to filter paper enzyme activity is not less than 25), hydrolyze at 50°C for 12h, then increase the temperature to 90°C, and continue hydrolysis for 36h. After the enzymolysis, the enzymolysis solution was centrifuged at 8000r / min for 10min. After centrifugation, the filtrate was passed through a 0.22 μm filter membrane, and after dilution, HPLC detection and analysis showed that the degradation rate of oleuropein was 100%, and the yield of hydroxytyrosol was 83.89% (the content was equivalent to 2.99g / L).

Embodiment 3

[0033] Measure 50 mL of oleuropein solution with a concentration of 10.0 g / L and place it in a 125 mL conical flask, add 50 FPU / g oleuropein rich in cellulase (Novozyme, β-glucosidase) The ratio of glucosidase activity to filter paper enzyme activity is not less than 25), hydrolyze at 50°C for 1 hour, then increase the temperature to 90°C, and continue hydrolysis for 47 hours. After the enzymolysis, the enzymolysis solution was centrifuged at 8000r / min for 10min. After centrifugation, the filtrate was passed through a 0.22 μm filter membrane, and after dilution, HPLC detection and analysis showed that the degradation rate of oleuropein was 100%, and the yield of hydroxytyrosol was 82.38% (the content was equivalent to 2.35g / L).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com