Pipeline water conveying system multi-point tiny leakage detection device and method

A technology for water delivery systems and leak detection, applied in pipeline systems, special data processing applications, instruments, etc., can solve problems such as the difficulty of capturing transient pressure waves, large water hammer pressure in pipelines, and low signal-to-noise ratio of measured signals. Achieve the effect of overcoming the inability to detect quickly, making the positioning formula easy, and avoiding simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

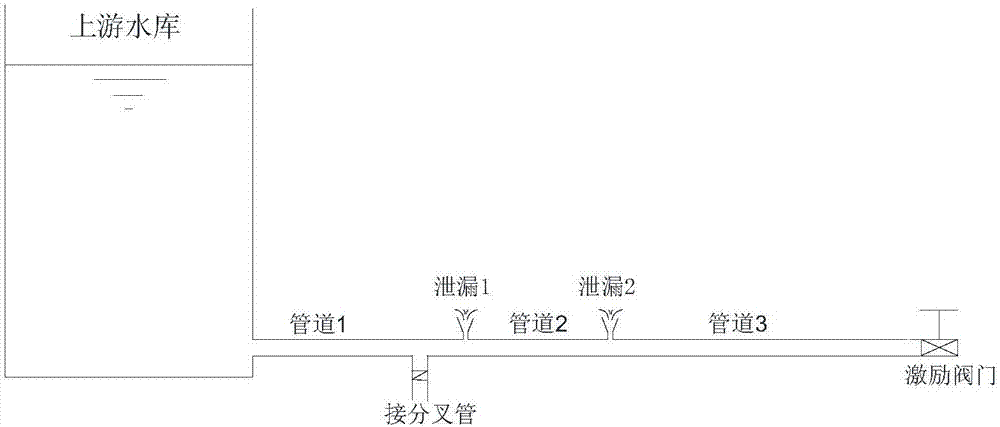

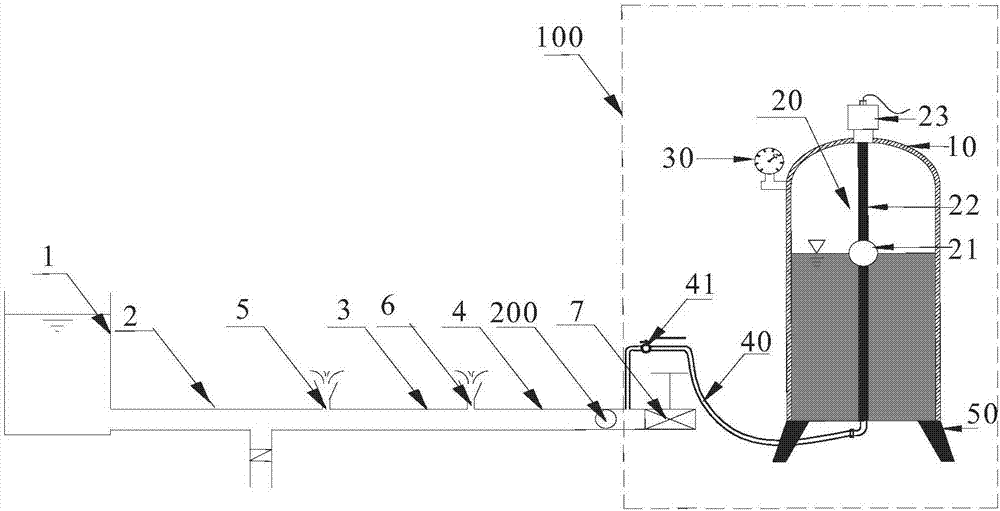

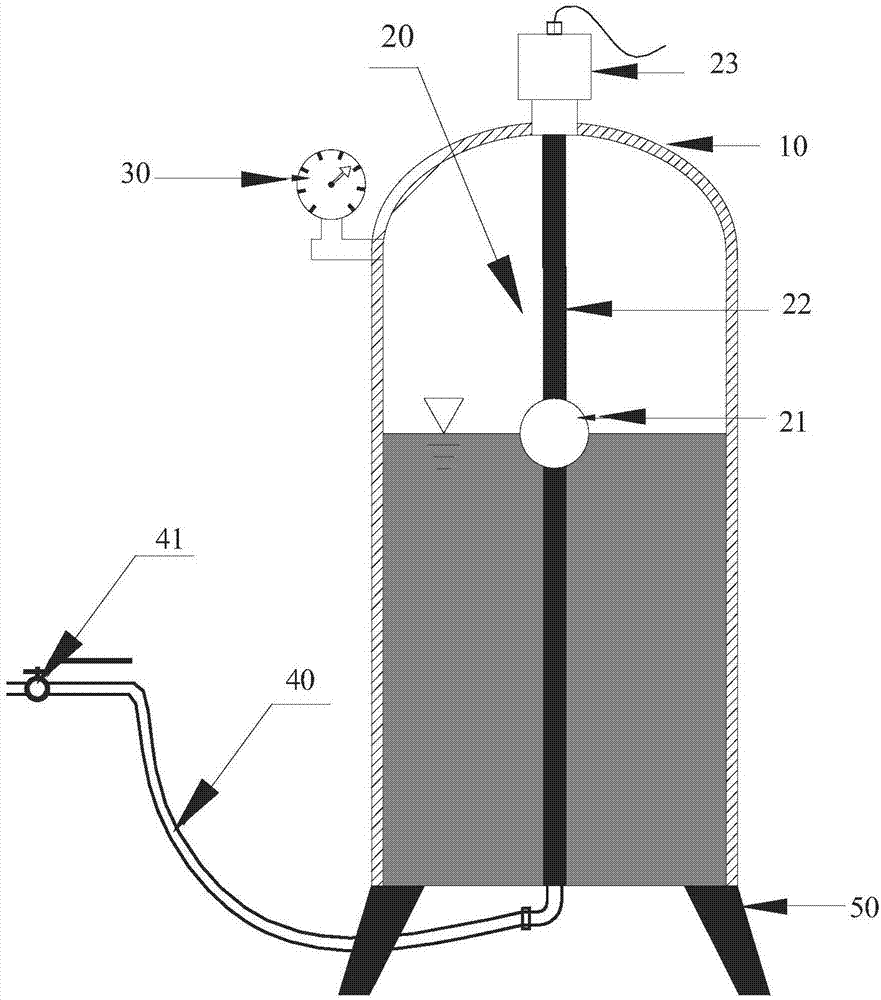

[0060] The present invention is applied to pipeline water delivery systems (including long-distance pipeline water delivery and municipal water supply pipelines) for the detection of small leak holes and multi-point leaks, and can quickly and accurately locate pipeline water delivery projects, water delivery and distribution projects only relying on a small amount of sensing information The technology of multi-point leakage in the pipeline is especially suitable for the complex situation of multi-point and small leakage holes. Wherein, the detection object of the present invention is tiny leakage, and the definition of tiny leakage is: Ag / A<0.5%, wherein Ag is the leakage hole area, and A is the corresponding pipeline flow area.

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0062] like figure 2 As shown, it is a schematic layout diagram of a multi-point micro-leakage detection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com