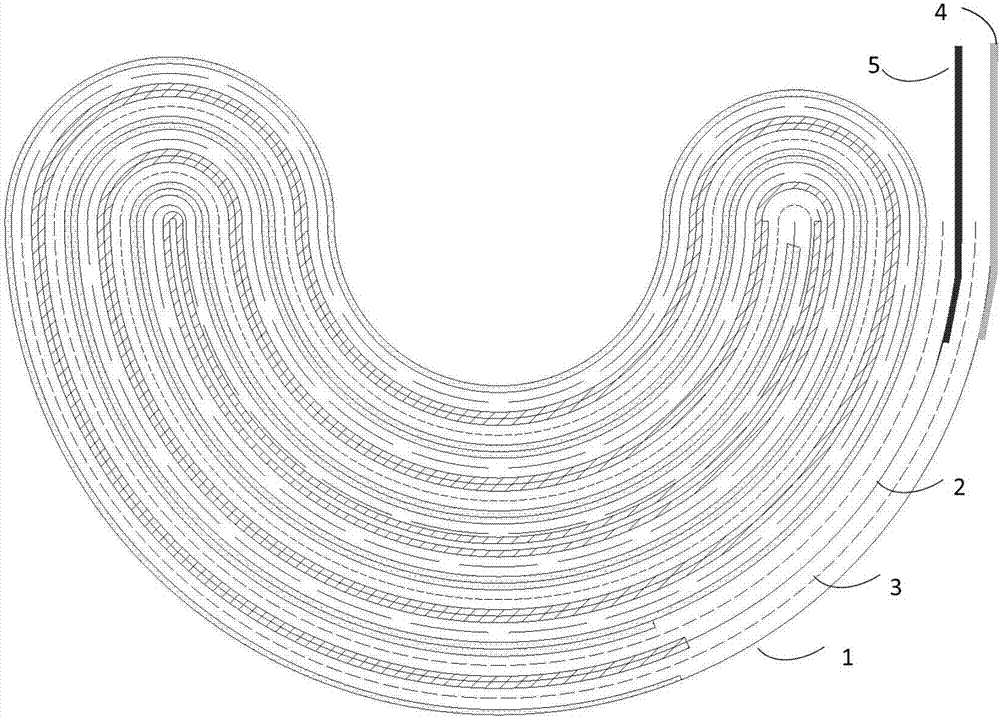

Arc-shaped lithium ion secondary battery and manufacturing method thereof

A secondary battery and manufacturing method technology, applied in the secondary battery, electrolyte storage battery manufacturing, battery electrode and other directions, can solve problems such as inability to meet, and achieve the effects of large bending arc, high reliability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

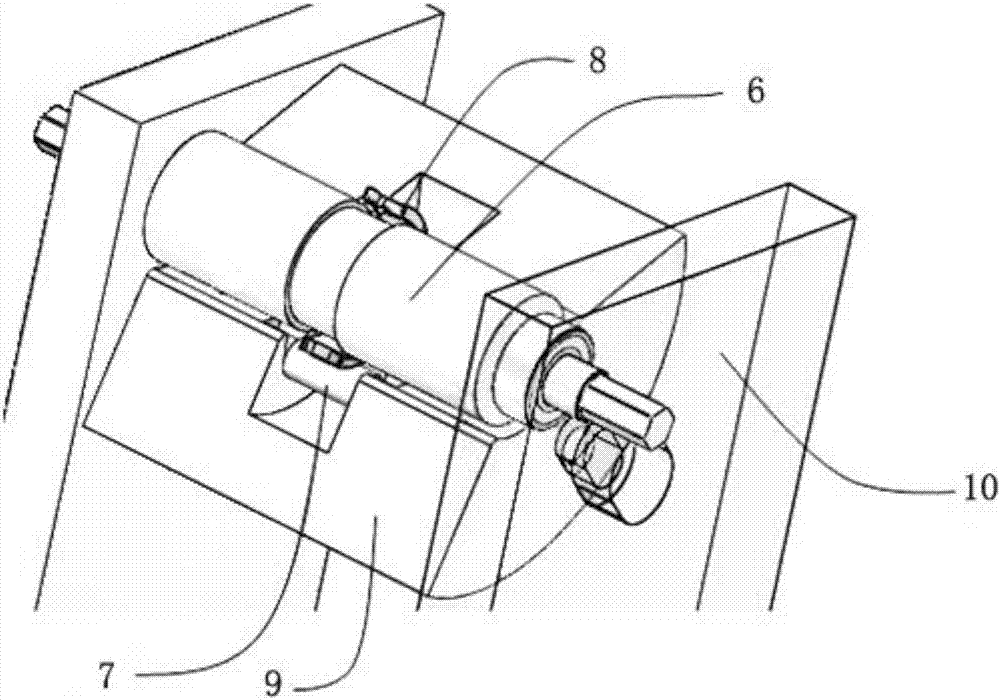

Method used

Image

Examples

preparation example Construction

[0040] Preparation of the positive pole piece: the positive active material lithium cobaltate, the binder polyvinylidene fluoride (PVDF) and the conductive agent Super-P are added to N-methylpyrrolidone (NMP) according to the weight ratio of 96:2:2 and stirred evenly The slurry is made into positive electrode slurry; the positive electrode slurry is double-coated on the positive electrode current collector, and the positive electrode sheet is obtained after drying, compacting, slitting, cutting, and welding tabs.

[0041] Preparation of negative electrode sheet: Negative electrode active material silicon-carbon composite material, styrene-butadiene rubber (SBR), sodium carboxymethyl cellulose (CMC), according to the ratio of 95:2.5:2.5, add deionized water and stir to make negative electrode slurry material; the negative electrode slurry is double-coated on the negative electrode current collector, and the negative electrode sheet is obtained after drying, compacting, slitting,...

Embodiment 1

[0066] Refer to the battery production instructions to prepare lithium-ion secondary batteries. The positive electrode collector uses aluminum alloy foil with a grade of 3003 and the state is H18 with a thickness of 20 μm, the negative electrode current collector uses copper foil with a thickness of 8 μm, and the separator uses polyethylene with a thickness of 12 μm. The diaphragm is processed into a curved shape with a bending jig.

Embodiment 2

[0068] Refer to the battery production instructions to prepare lithium-ion secondary batteries. The positive electrode current collector uses aluminum alloy foil with a grade of 3003 and the state is H18 with a thickness of 20 μm. The negative electrode current collector uses copper foil with a thickness of 8 μm. The separator uses a non-woven separator with a thickness of 25 μm. , processed into an arc with a bending jig.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com