Miniaturized capacitive vacuum pressure sensor encapsulation structure

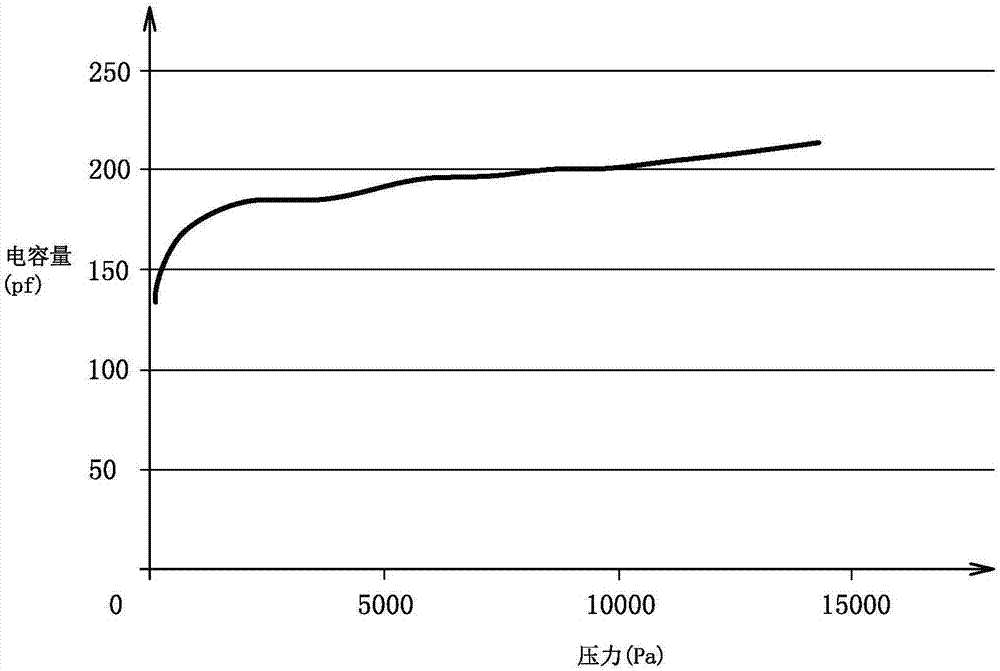

A technology of vacuum pressure and packaging structure, which is applied in fluid pressure measurement using capacitance changes, vacuum gauges, and fluid pressure measurement. It can solve the problems of small electrode plate gap, low overload resistance, and large capacitor electrode diameter. The effect of small force bearing area and high assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

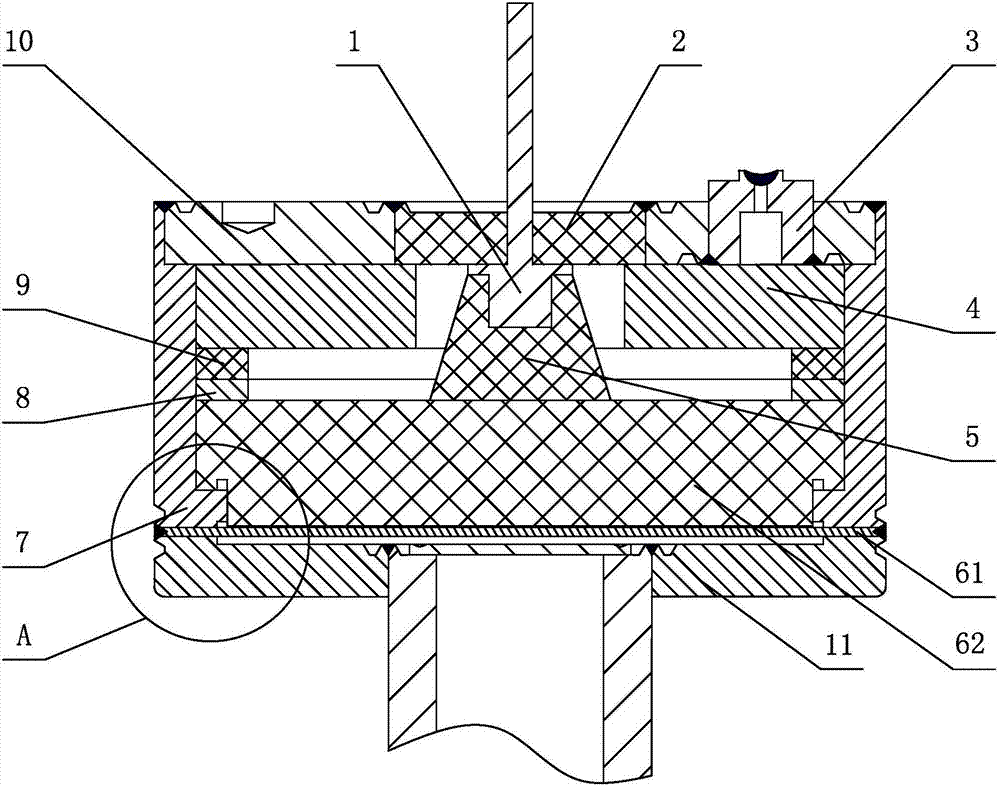

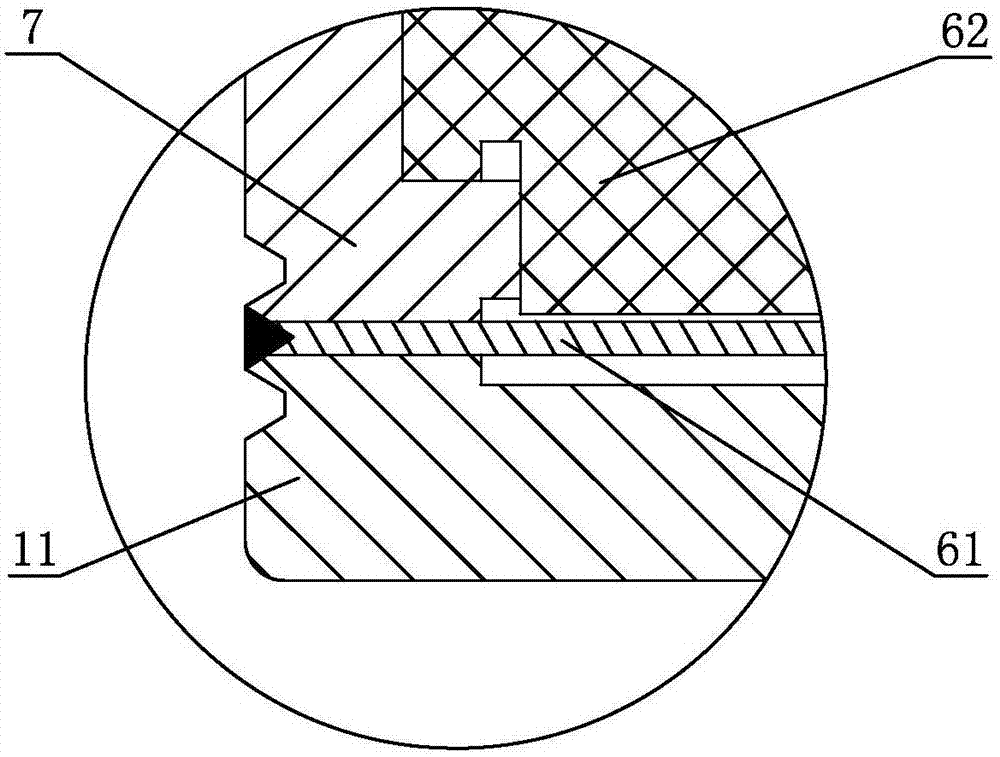

[0025] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a package structure of a miniaturized capacitive vacuum pressure sensor in this embodiment, which includes a pin 1, an adapter terminal 2, a sealing joint 3, a solid getter 4, a conductive rubber 5, a casing 7, an upper Cover 10, lower cover 11, metal moving electrode 61 and static electrode 62;

[0026] The upper cover 10, the casing 7, the metal moving electrode 61 and the lower cover 11 are arranged in sequence from top to bottom, the lower end surface of the metal moving electrode 61 is fixedly connected to the upper end surface of the lower cover 11, and the upper end surface of the metal moving electrode 61 is connected to the bottom surface of the casing 7. The lower end is fixed, the upper cover 10 is fixedly installed on the upper end of the housing 7, a through hole is opened in the center of the upper cover 10, the transfer terminal 2 is installed in the through hole o...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment also includes an adjustment gasket 8, which is a metal gasket. Conductive rubber 5 on. With such arrangement, the adjusting washer 8 can ensure the assembly accuracy of the solid getter 4 and the static electrode 62 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment also includes an insulating washer 9, the insulating washer 9 is a washer made of ceramic material, the insulating washer 9 is installed in the vacuum sealed cavity, the insulating washer 9 is located between the solid getter 4 and the adjusting washer 8 and is set in the Conductive rubber 5 on. In this setting, insulation needs to be done during the signal lead-out process, in order to prevent the introduction of other interference signals. An insulating gasket 9 is added in the vacuum sealed cavity. When the metal coating on the surface of the static electrode 62 is not uniform, the insulating gasket 9 can effectively avoid the introduction of interference signals due to the adjustment of the gasket 8 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com