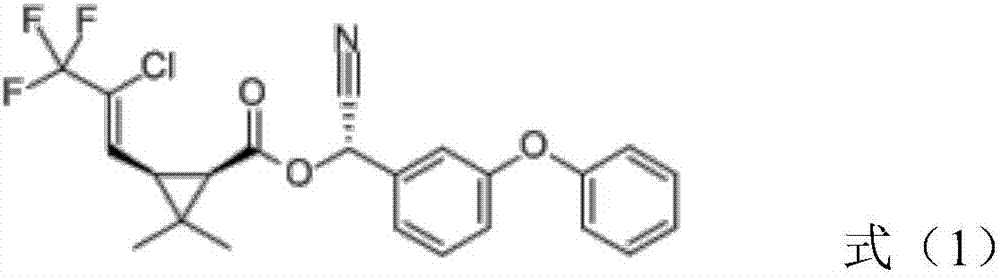

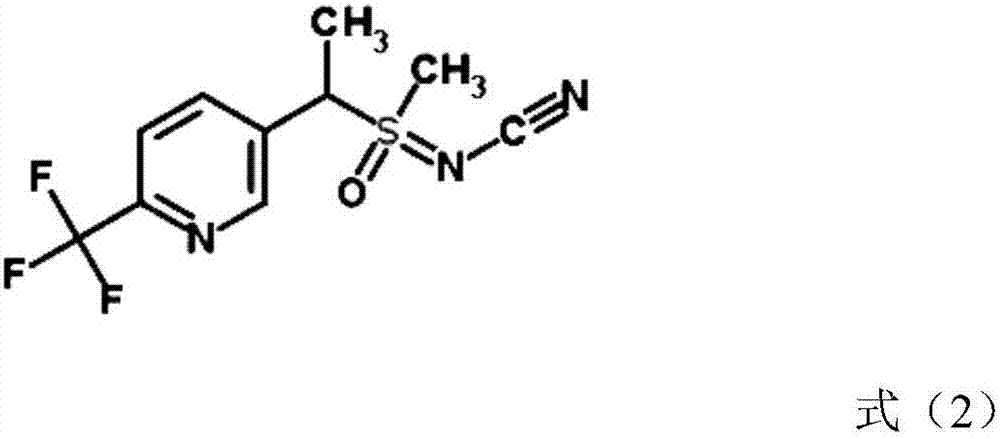

Microcapsule suspension-suspending agent containing efficient cyhalothrin and sulfoxaflor and preparation method thereof

A technology of high-efficiency cyhalothrin and microcapsule suspension, which is applied in the field of pesticides to achieve the effects of delaying the generation of drug resistance, prolonging the service life and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a preparation method of a microcapsule suspension-suspension agent containing lambda-cyhalothrin and sulfoxaflor, wherein the preparation method may include the following steps: S1, beta-cyhalothrin, The inert solvent oil and the emulsifier are mixed and ground until the D90 value is less than 5 μm to obtain the first material; S2, the first material obtained in step S1 can be uniformly mixed with the urea-formaldehyde resin prepolymer aqueous solution to obtain the second material; S3. A buffer solution can be added to the second material obtained in step S2 and mixed evenly to adjust the pH value of the second material to 5-7 to obtain a third material; S4. The second material can be obtained in step S3. Add an acidic pH adjuster to the third material and mix evenly to adjust the pH of the third material to 2-5.5 to obtain a fourth material; S5, the fourth material obtained in step S4 can be solidified polycondensation to obtain a solidified pol...

Embodiment 1

[0042] Mix urea with a formaldehyde aqueous solution with a concentration of 40% by weight, and react for 1.5 hours at a pH value of 8 and a temperature of 70° C.; add water to dilute to obtain an aqueous solution of urea-formaldehyde resin prepolymer, wherein the formaldehyde and urea The molar ratio is 1:0.5, and the volume ratio of water and formaldehyde solution is 1:2.

[0043] Mix beta-cyhalothrin, methyl oleate and sorbitan monostearate polyoxyethylene ether evenly, and grind until the D90 value is below 5 microns to obtain the first material, wherein the beta-chlorine The weight ratio of cyfluthrin to methyl oleate and sorbitan monostearate polyoxyethylene ether is 1:3:0.05.

[0044] The obtained urea-formaldehyde resin prepolymer aqueous solution and the first material are mixed uniformly to obtain the second material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution and the first material is 1:3; at room temperature, Add the acetic...

Embodiment 2

[0048] Mix urea with a formaldehyde aqueous solution with a concentration of 35% by weight, and react for 1.0 h at a pH value of 8 and a temperature of 70° C.; add distilled water to dilute to obtain an aqueous solution of urea-formaldehyde resin prepolymer, wherein the formaldehyde and urea The molar ratio is 1:0.5, and the volume ratio of water and formaldehyde solution is 1:2.

[0049] Mix high-efficacy cyhalothrin, soybean oil and sorbitan monostearate polyoxyethylene ether, and grind until the D90 value is below 5 microns to obtain the first material, wherein the high-efficiency chlorofluorocyano The weight ratio of permethrin to soybean oil and sorbitan monostearate polyoxyethylene ether is 1:2.5:0.05.

[0050]The obtained urea-formaldehyde resin prepolymer aqueous solution and the first material are mixed uniformly to obtain the second material, wherein the weight ratio of the urea-formaldehyde resin prepolymer aqueous solution and the first material is 1:5; at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com