Healing promoting type first-aidhemostatic powderand preparation method thereof

A hemostatic powder and the technology of its preparation steps are applied in the field of healing-promoting emergency hemostatic powder and its preparation, which can solve the problems of insufficient strength of blood clots and long healing time, so as to improve local microcirculation, promote cell regeneration, and reduce pain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

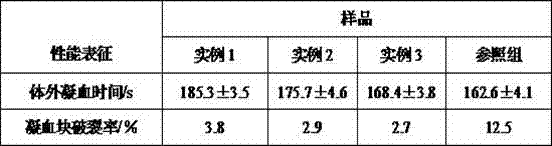

Examples

example 1

[0022] Mix pig bones with acetone at a mass ratio of 1:10, soak them at room temperature for 20 hours, take out the defatted pig bones and wash them with 10% hydrogen peroxide for 3 times, then rinse them with deionized water for 3 times, and vacuum freeze-dry the pigs. bone, crush the dried pig bone and place it in a ball mill jar, mill it at 350r / min for 3h, pass through a 200-mesh sieve to get the pig bone powder, place the pig bone powder in a tubular atmosphere furnace, and calcinate at 550°C for 6h, Stand to cool to room temperature, and grind to obtain calcined particles; take deer antler and notoginseng leaves separately, wash and dry, mix and grind notoginseng leaves and velvet antler at a mass ratio of 1:5, pass through a 150-mesh sieve to obtain a mixed ball mill Granules, according to the mass ratio of 1:10, mix the mixed ball-milled granules with deionized water, heat in a water bath at 55°C for 2 hours, filter to obtain the filtrate, and rotary evaporate at 45°C t...

example 2

[0024]Mix pig bones with acetone at a mass ratio of 1:10, soak them at room temperature for 22 hours, take out the defatted pig bones and wash them with 10% hydrogen peroxide for 4 times, then rinse them with deionized water for 4 times, and vacuum freeze-dry the pigs. bone, crush the dried pig bone and place it in a ball mill jar, mill it at 375r / min for 4h, pass through a 200-mesh sieve to get the pig bone powder, place the pig bone powder in a tubular atmosphere furnace, and calcinate it at 575°C for 7h, Stand to cool to room temperature, and grind to obtain calcined particles; take deer antler and notoginseng leaves separately, wash and dry, mix and grind notoginseng leaves and velvet antler at a mass ratio of 1:5, pass through a 150-mesh sieve to obtain a mixed ball mill Granules, according to the mass ratio of 1:10, mix the mixed ball-milled granules with deionized water, heat in a water bath at 57°C for 3 hours, filter to obtain the filtrate, and rotary evaporate at 47°C...

example 3

[0026] Mix pig bones with acetone at a mass ratio of 1:10, soak them at room temperature for 24 hours, take out the defatted pig bones and wash them with 10% hydrogen peroxide for 5 times, then rinse them with deionized water for 5 times, and vacuum freeze-dry the pigs. bone, crush the dried pig bone and place it in a ball mill jar, mill it at 400r / min for 5h, pass through a 200-mesh sieve to get the pig bone powder, place the pig bone powder in a tubular atmosphere furnace, and calcinate at 600°C for 8h, Stand to cool to room temperature, and grind to obtain calcined particles; take deer antler and notoginseng leaves separately, wash and dry, mix and grind notoginseng leaves and velvet antler at a mass ratio of 1:5, pass through a 150-mesh sieve to obtain a mixed ball mill Granules, according to the mass ratio of 1:10, mix the mixed ball-milled granules with deionized water, heat in a water bath at 60°C for 3 hours, filter to obtain the filtrate, and rotary evaporate at 50°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com