Cobamamide crystal form and preparation method and application thereof

A technology of adenosylcobalamin crystal and adenosylcobalamin, which is applied in the field of adenosylcobalamin crystal form and its preparation, can solve the problem that the adenosylcobalamin raw material is not completely dissolved, and achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

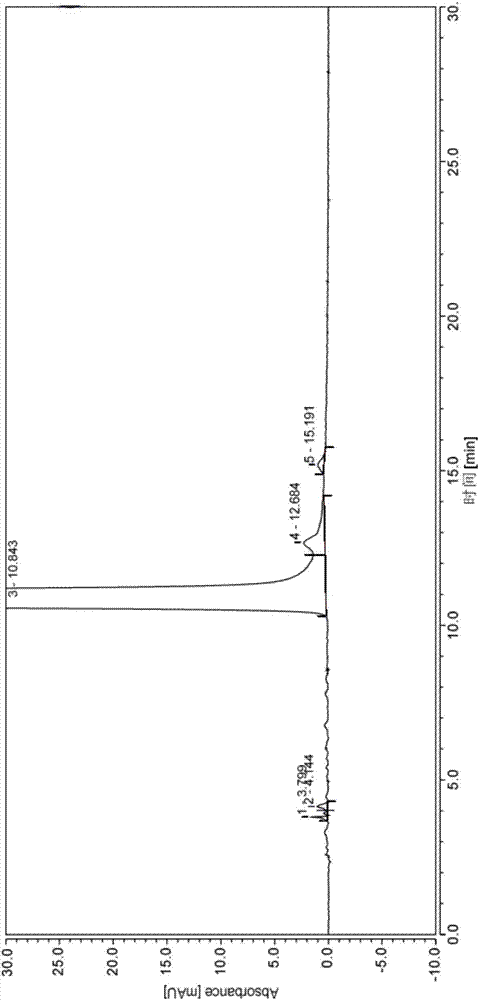

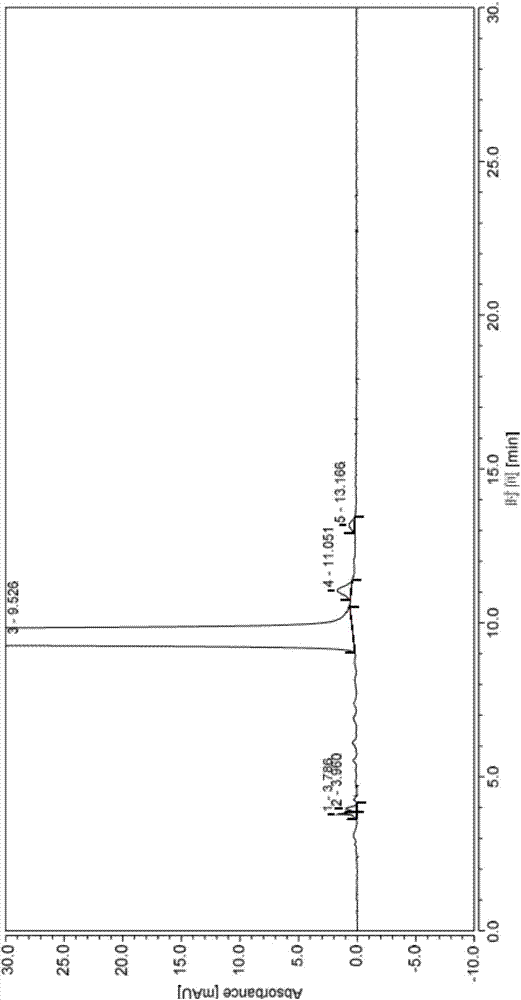

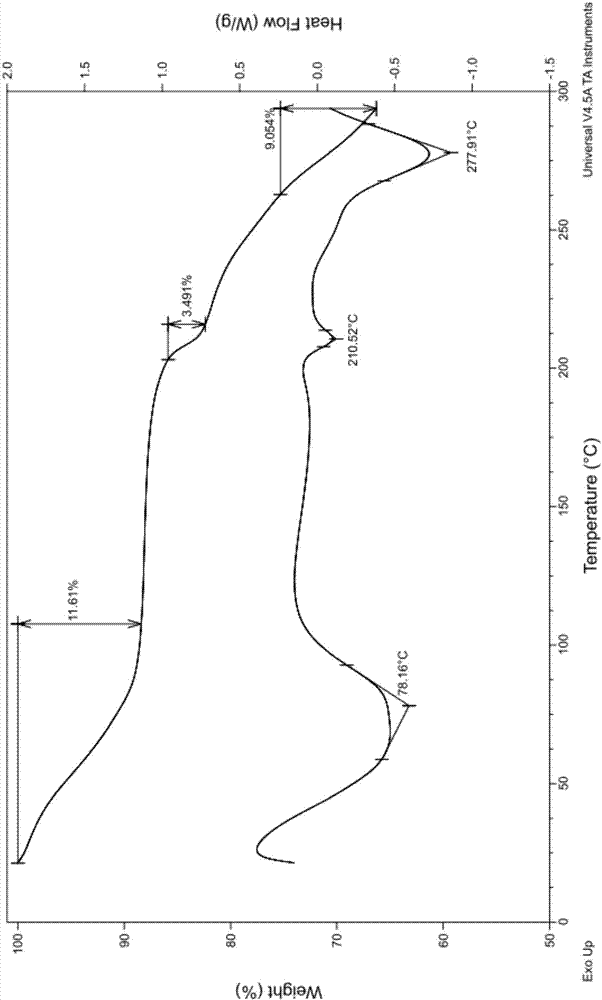

[0077] Under red light lighting conditions, at room temperature. Add 1 g of commercially available adenosylcobalamin to 7ml of water, stir for 5 minutes until it becomes a paste, keep stirring, add 3.5ml of acetone to the above paste, and within 1 minute, adenosylcobalamin is completely dissolved to obtain a clear solution. Add 35ml of isopropanol to the above solution, while stirring for 5min, the stirring rate is controlled at 400r / min, and the system is cloudy at this time. Then, let stand overnight at room temperature, suction-filter the precipitated crystals, wash the filter cake with isopropanol (3*10ml), and vacuum-dry at 25°C for 7 hours to obtain 0.982g of crystal form C adenosylcobalamin with a yield of 98.2%.

[0078] The X-powder diffraction pattern of obtained C crystal form adenosylcobalamin and Figure 4 Consistent, the TG-DSC spectrum is consistent with Figure 9 unanimous. Content analysis was carried out according to the detection method of Chinese Pharmac...

experiment example 2

[0080] Under red light lighting conditions, at room temperature. Add 10 g of commercially available adenosylcobalamin to 60ml of water, stir for 10 minutes until it becomes a paste, keep stirring, add 24ml of acetone to the above paste, within 3 minutes, adenosylcobalamin is completely dissolved to obtain a clear solution. Add 156ml of isopropanol to the above solution, and stir for 5 minutes at the same time, the stirring rate is controlled at 300r / min, and the system is cloudy at this time. Then, let stand overnight at room temperature, suction-filter the precipitated crystals, wash the filter cake with isopropanol (3*20ml), and vacuum-dry at 25°C for 7 hours to obtain 9.930g of crystal form C adenosylcobalamin with a yield of 99.3%.

[0081] The X-powder diffraction pattern of obtained C crystal form adenosylcobalamin and Figure 4 Consistent, the TG-DSC spectrum is consistent with Figure 9 unanimous. Content analysis was carried out according to the detection method of...

experiment example 3

[0083] Under red light lighting conditions, at room temperature. Add 50 g of commercially available adenosylcobalamin to 250ml of water, stir for 30 minutes until it becomes a paste, keep stirring, add 75ml of acetone to the above paste, within 10 minutes, adenosylcobalamin is completely dissolved to obtain a clear solution. Add 250ml of isopropanol to the above solution, while stirring for 1min, the stirring rate is controlled at 100r / min, at this time the system gradually becomes cloudy. Then, let stand overnight at room temperature, suction-filter the precipitated crystals, wash the filter cake with isopropanol (3*50ml), and vacuum-dry at 25°C for 7 hours to obtain 49.200g of crystal form C adenosylcobalamin with a yield of 98.4%.

[0084] The crystal grain size obtained under this condition can reach 0.2 mm, which can be used for X-single crystal diffraction detection. The single crystal diffraction pattern is shown in image 3 , the X-powder diffraction pattern of the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com