Preparation and application of vinylphenyl polysiloxane resin containing epoxy groups in side groups

A technology of polysiloxane resin and vinyl phenyl, which is applied in the field of polymer material synthesis and preparation, can solve the problems of addition-type silicone resin mechanical properties and other performance effects, corrosiveness of raw materials, complex preparation process, etc., and achieve improvement The effect of low bond strength, complementary properties, and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

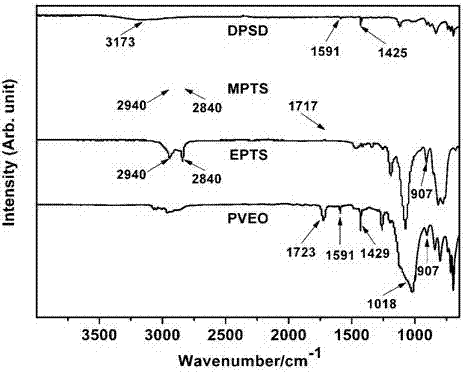

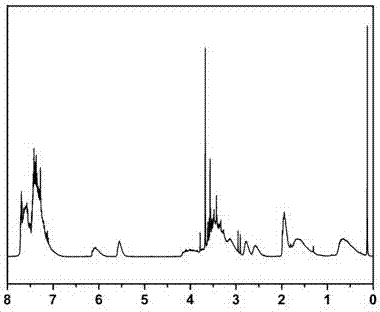

[0026] The preparation of the vinyl phenyl polysiloxane resin that side group contains epoxy group:

[0027] Add 236.34 grams of γ-glycidyl etheroxypropyltrimethoxysilane, 41.39 grams of γ-(methacryloyloxy)propyltrimethoxysilane and 288.41 grams of diphenylsilanediol into the three-necked flask, and then add 28.31 201x4 grams of anion exchange resin (the amount of anion exchange resin added is 5% of the total mass of the monomer), protected by nitrogen gas, the temperature of the water bath was raised to 70°C, the condensation reaction was carried out for 8 hours, and then the low pressure was removed at 100°C / 0.096MPa Boiler, remove the anion exchange resin by filtration to obtain vinyl phenyl polysiloxane resin with epoxy group in the side group. γ-glycidyl etheroxypropyltrimethoxysilane, γ-(methacryloyloxy)propyltrimethoxysilane and diphenylsilanediol are represented by a, b and c in sequence, a:b:c Molar ratio=3:0.5:4, the sum of the contents of γ-glycidyl etheroxypropyl ...

Embodiment 2

[0031] The preparation of the vinyl phenyl polysiloxane resin that side group contains epoxy group:

[0032] Add 144.23g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, 145.21g of methacryloxypropyltriethoxysilane and 216.30g of diphenylsilanediol into the three ports Into the flask, add 40.46g of anion exchange resin 201x7 (the amount of anion exchange resin added is 8% of the total mass of the monomer), protect it with nitrogen, raise the temperature of the water bath to 50°C, and perform condensation reaction for 12 hours, then at 100°C / 0.096 MPa reduced pressure to remove low boilers, filter to remove anion exchange resin, to obtain vinyl phenyl polysiloxane resin with epoxy group in side group. 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, methacryloxypropyltriethoxysilane and diphenylsilanediol are represented by a, b and c in sequence , the molar ratio of a:b:c=2:2:4, 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane and methacryloxypropyltriethoxy The sum of the silane cont...

Embodiment 3

[0034] The preparation of the vinyl phenyl polysiloxane resin that side group contains epoxy group:

[0035] Add 34.80g of 3-glycidyloxypropyltriethoxysilane, 175.74g of 3-(acryloyloxy)propyltrimethoxysilane and 216.31g of diphenylsilanediol into the three-necked flask, then add 21.34g of anion exchange resin 205x7 and 21.35g of anion exchange resin D280 (the amount of anion exchange resin added is 10% of the total mass of the monomer), nitrogen protection, the temperature of the water bath is raised to 25 ° C, condensation reaction for 15 hours, and then at 100 ° C / 0.096MPa to remove low boilers under reduced pressure, filter to remove anion exchange resin, and obtain vinyl phenyl polysiloxane resin with epoxy groups in side groups. 3-glycidyloxypropyltriethoxysilane, 3-(acryloyloxy)propyltrimethoxysilane and diphenylsilanediol are represented by a, b and c in sequence, a:b:c Molar ratio = 0.5:3:4, the sum of the contents of 3-glycidyloxypropyltriethoxysilane and 3-(acryloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com