A compact condensing fuel gas boiler with enhanced heat exchange cascade cooling

A technology for strengthening heat exchange and gas-fired boilers. It is used in steam/steam condensers, combustion using liquid fuels and gaseous fuels, and combustion equipment. Problems such as unreasonable planning of boiler accessory modules to avoid thermal efficiency reduction, reduce the number of tube passes, and eliminate damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

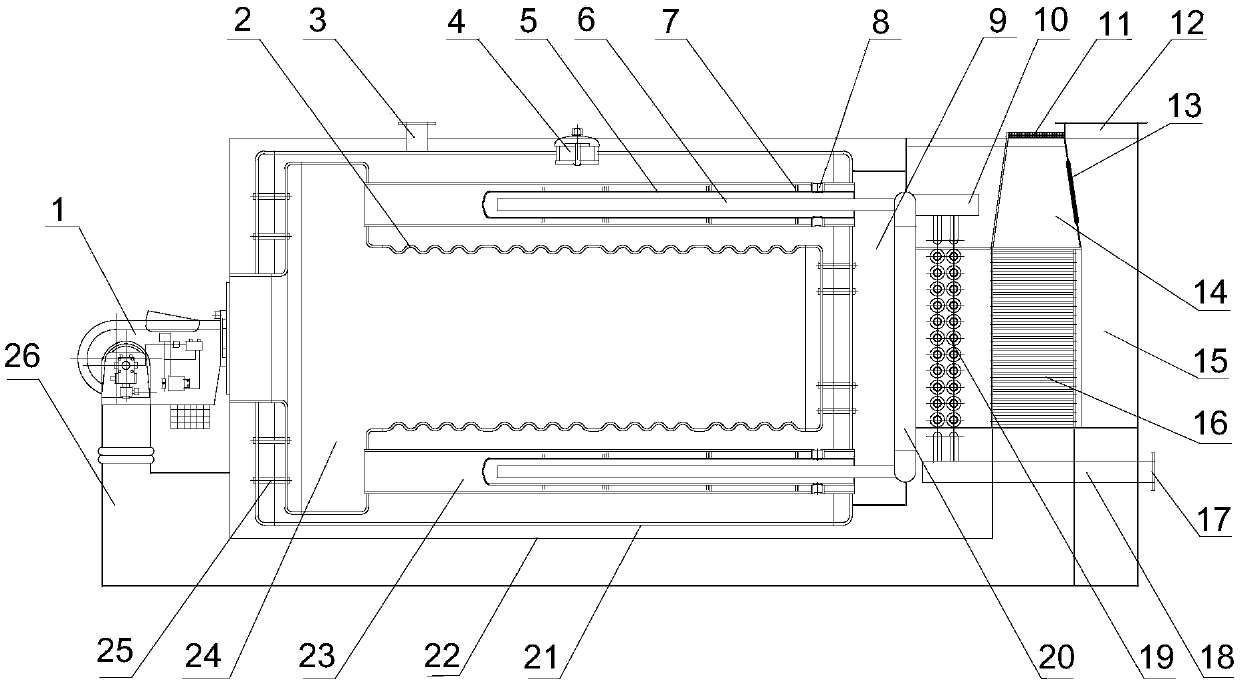

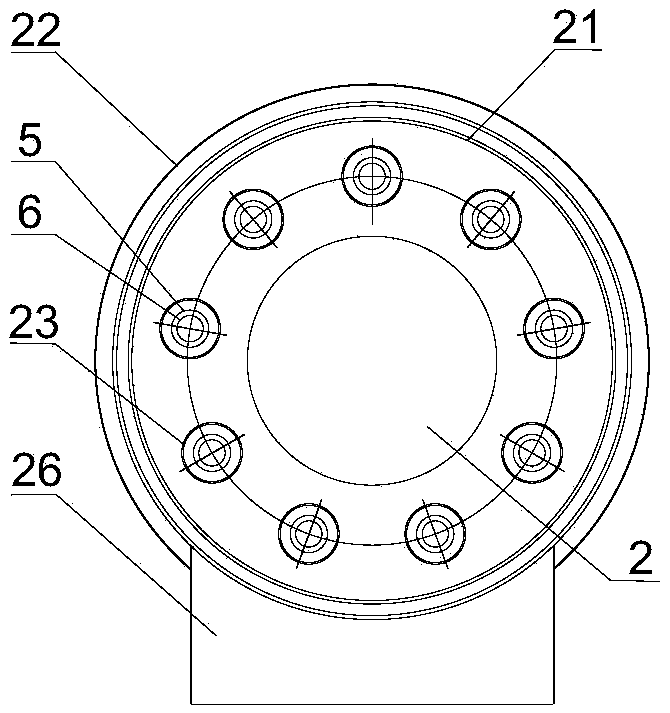

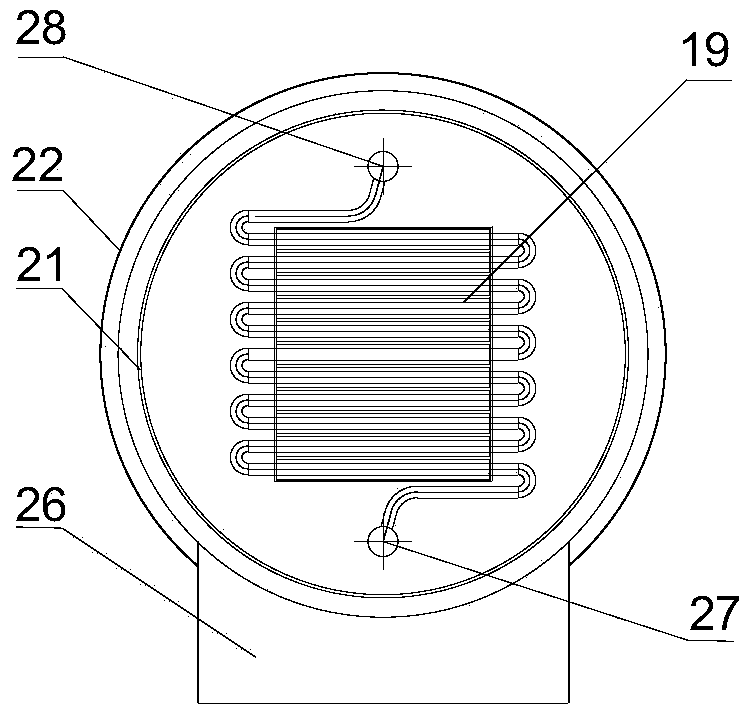

[0047] Such as figure 1 As shown, the present invention is a compactly arranged shell-type fire tube fuel gas steam and hot water boiler equipment, including a new type of smoke tube enhanced heat exchange device, flue gas condensation and flue gas recirculation system; specifically including from outside to inside Boiler shell 22, drum 21 and furnace 2 are arranged in sequence. Manhole 4 is set on boiler shell 22 and drum 21, and fixing device 25 is arranged between drum 21 and furnace 2; Device 1.

[0048] In this embodiment, the burner 1 is a diffuser burner, and the front side of the furnace 2 is covered with a combustion chamber 24, and the furnace 2 and the combustion chamber 24 are connected to form a horizontal T-shaped structure; A plurality of smoke pipes 23 uniformly surrounding are arranged on the outside, and the back combustion chamber 24 communicates with the front ends of the smoke pipes 23 .

[0049] Between the drum 21 and the boiler shell 22, the first flu...

Embodiment 2

[0064] Such as Figure 7 and Figure 8 As shown, the burner 1 in this embodiment is also a diffuser burner, and the reburning chamber 24 is arranged on the front side of the furnace 2. The combustion chamber 24 is connected; the front end of the furnace 2 and the outlet of the burner 1 are sealed and connected by a sealing baffle 31 ; the smoke pipe 23 surrounds the outside of the furnace 2 evenly.

[0065] Other structures are the same as in Embodiment 1. This embodiment is suitable for boilers with a capacity greater than 8t / h (or 5.6MW).

Embodiment 3

[0067] Such as Figure 9 and Figure 10 As shown, the burner 1 in this embodiment is an ejector type burner, the reburning chamber 24 is sleeved outside the rear of the furnace 2 , and the front ends of the smoke pipes 23 are located at the rear of the furnace 2 .

[0068]Other structures are the same as in Embodiment 1. This embodiment is suitable for burners that produce relatively short flames.

[0069] Main working process and principle of the present invention:

[0070] When the boiler capacity is less than or equal to 8t / h (or 5.6MW), the fuel or gas is mixed with air to burn through the burner 1 and generate flue gas. The burning flame and flue gas move backward along the center of the furnace 2 and pass through the furnace 2. After radiative heat exchange, turn 180° from the center of the rear of the furnace 2 and move forward along the inner wall of the furnace 2. During this period, co-combustion can occur with the central combustion flame, forming a reducing atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com