Integrated containment filtrate exhaust system

A discharge system and filtration system technology, which is applied in radioactive purification, greenhouse gas reduction, nuclear power generation, etc., can solve problems such as silver zeolite failure, achieve space saving, simple structure, and solve the effects of moisture absorption failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

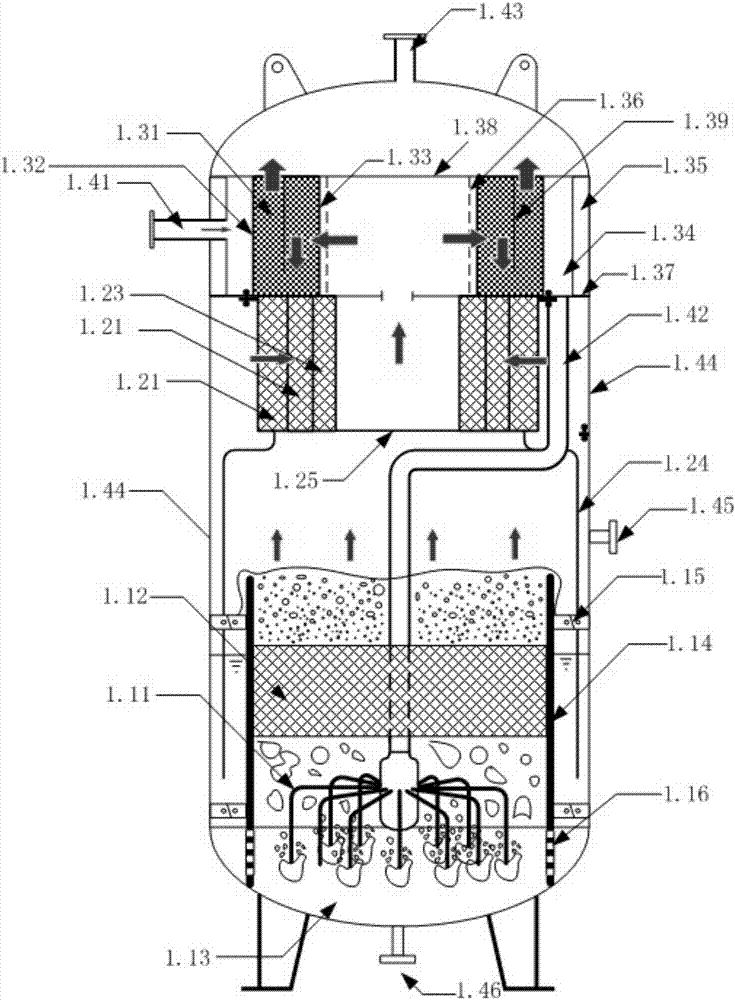

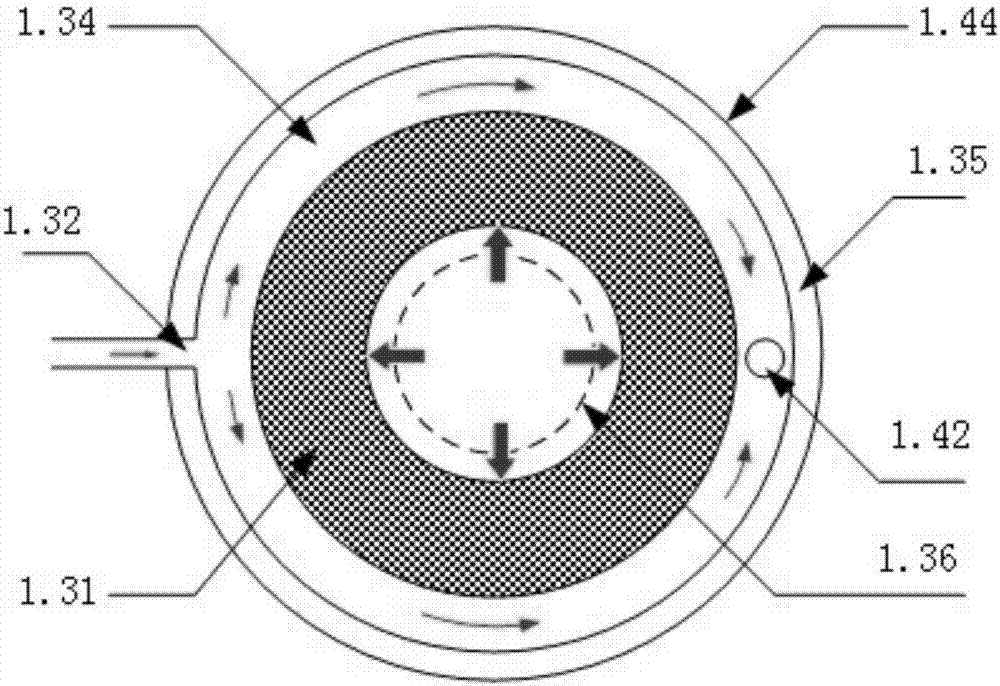

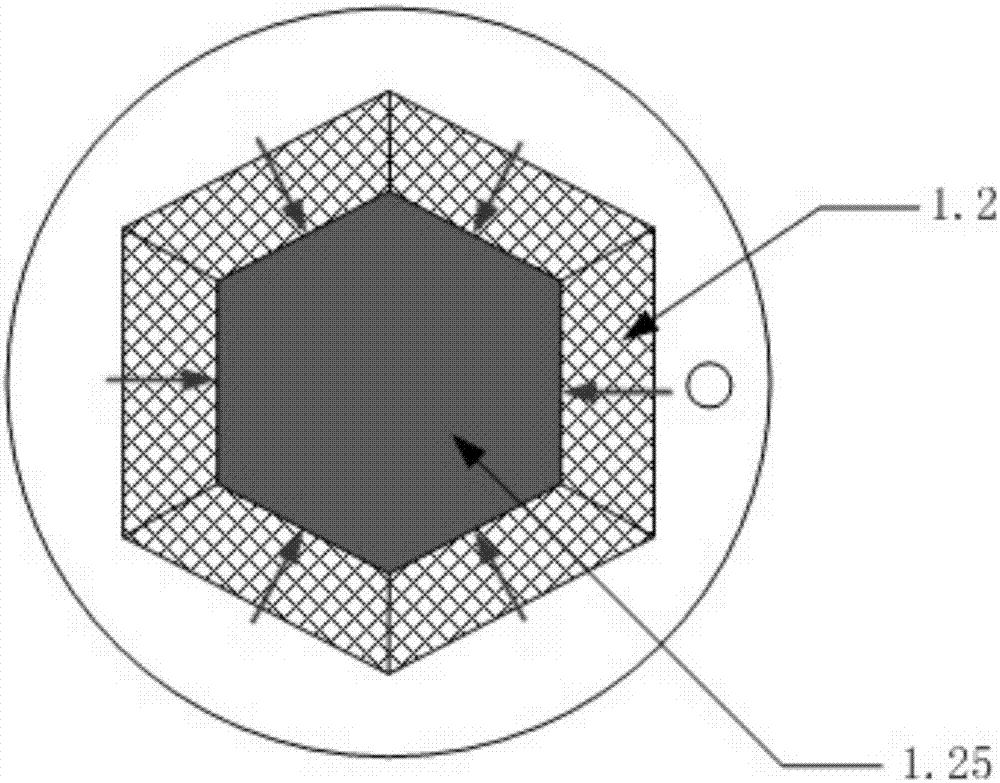

[0022] combine Figure 1-3 , the present invention is mainly composed of wet filter system 1.1, metal fiber filter system 1.2, silver zeolite filter system 1.3 and system pressure boundary 1.4.

[0023] The wet filtration system 1.1 includes a jet gas discharge tube bundle assembly 1.11, a static mixing assembly 1.12, a cylindrical liner 1.14 and a chemical washing solution 1.13. The jet-type gas discharge tube bundle assembly 1.11 is a gas discharge channel composed of a series of parallel tube bundles. The outlet of the tube bundle is immersed in the chemical solution 1.13. When the system is put into operation, the exhaust gas from the containment passes through the annular preheating channel 1.34 and exhaust The gas main pipe 1.42 is discharged into the chemical solution 1.13 from the outlet of the tube bundle. The number and diameter of the gas discharge tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com