Biquaternary ammonium salt surfactant and synthetic method thereof

A technology of surfactant and biquaternary ammonium salt, which is applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc. The cost of construction, the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now, the present invention will be further described through specific embodiments.

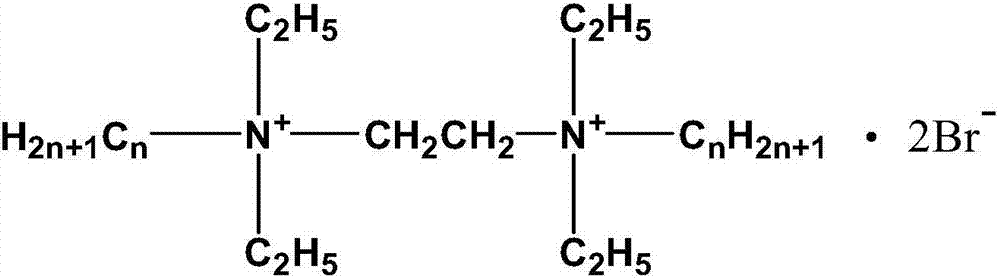

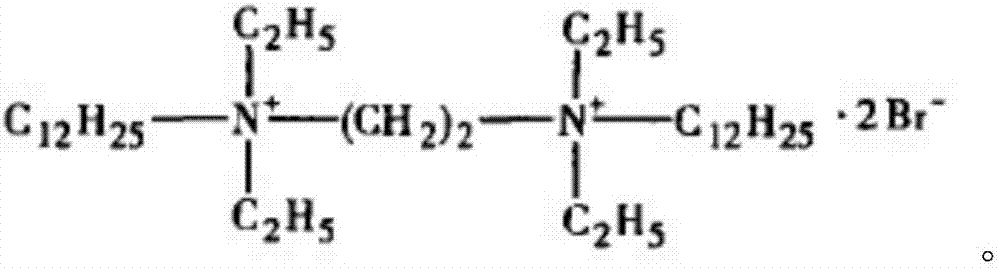

[0029] Preferred double quaternary ammonium salt surfactant of the present invention, its chemical name is double quaternary ammonium salt dibromide N, N-two (long-chain alkyl dimethyl)-3-oxa-1,5-pentanedi Ammonium, the structural formula is as follows:

[0030]

[0031] The synthetic method of double quaternary ammonium salt surfactant of the present invention, comprises the following steps:

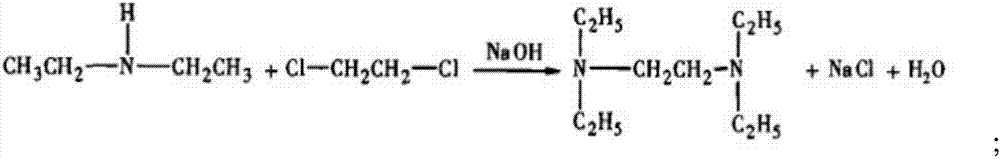

[0032] (1) Add 0.1mol diethylamine in a three-necked flask equipped with a stirrer and 2 dropping funnels, then add 0.05mol dichloroethane and 0.05mol weight / volume percentage in 2 dropping funnels respectively. 40% sodium hydroxide solution, react in a constant temperature water bath at 20°C, while stirring at a low speed with the stirrer at a speed of 40 rpm, add dichloroethane and sodium hydroxide solution alternately in a dropwise manner , make tetraethylethylenediamine, its chemical rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com