A reaction device, a reaction system and a liquid-phase hydrogenation reaction method

A liquid-phase hydrogenation and reaction system technology, which is applied in the field of hydrocarbon oil hydrogenation, can solve problems such as adverse effects on the reaction rate of the hydrogenation treatment process, achieve good hydrogenation reaction effects, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

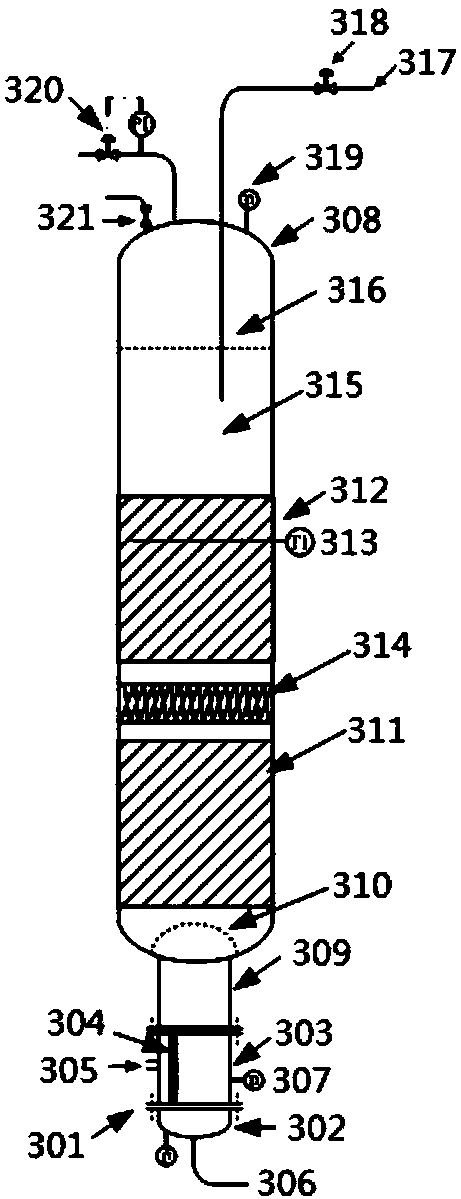

[0120] This example is in Figure 4 shown in the reaction system, wherein, using image 3 The reaction setup is shown.

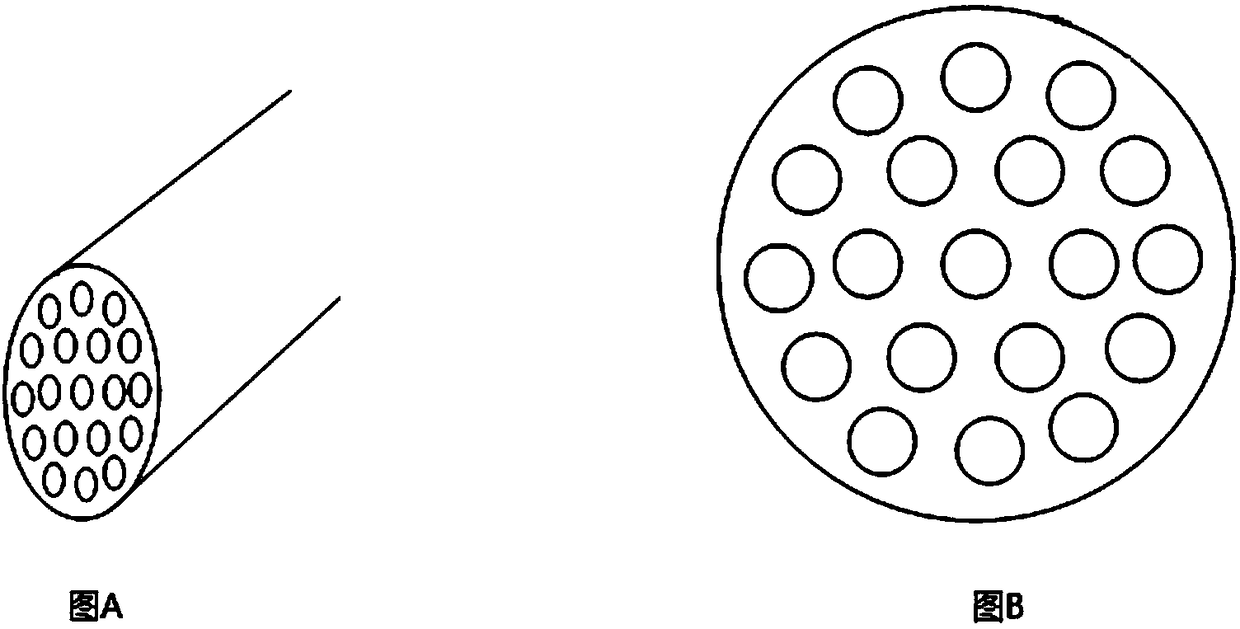

[0121] The component in the mixer is a pipeline with a porous wall (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., the cross-section of the pipeline is as follows: figure 1 As shown, there are 19 liquid channels evenly distributed on the pipeline, the inner diameter of each liquid channel is 3.3mm, the average pore diameter of the pores on the tube wall is 50nm, and the proportion of pores with a pore diameter in the range of 50-55nm to the total pores is 98%, porosity 20%), the pipe is used in conjunction with a shell, the space formed by the outer wall of the pipe and the inner wall of the shell is a raw material channel, and the channel on the pipe body is a mixing channel. The ratio between the inner diameter of the raw material mixture outlet on the mixer, the inner diameter of the reaction raw material inlet on...

Embodiment 2

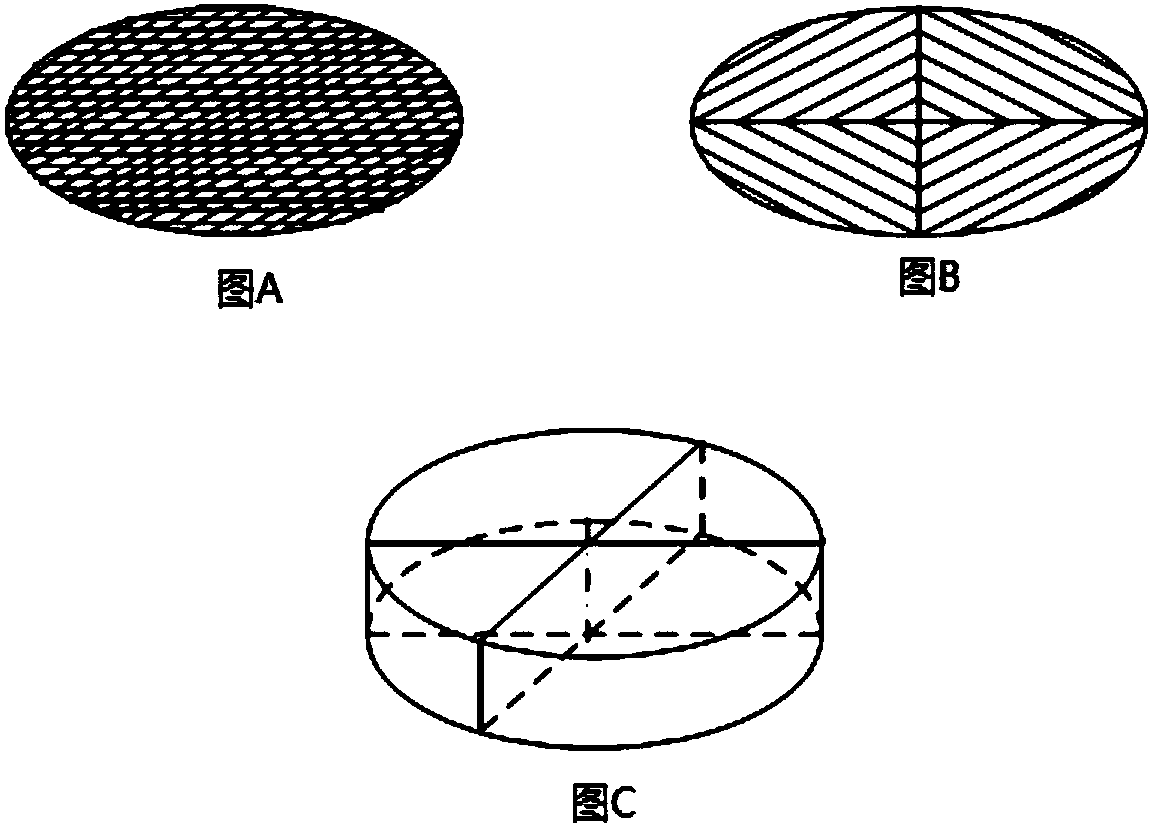

[0130] The hydrogenation reaction is carried out in the same manner as in Example 1, except that instead of a porous screen, a rib-type separation member is set between the catalyst beds, wherein the number of ribs is two, and two The ribs are arranged in a criss-cross pattern, which divides the radial section of the ribs into four pieces with equal areas. The property parameters of the resulting stripped product stream are listed in Table 1.

Embodiment 3

[0132] Adopt the method identical with embodiment 1 to carry out hydrogenation reaction, difference is, the separating member that is provided with between catalyst bed is porous screen cloth (same as embodiment 1) and rib plate type separating member (same embodiment 2), Wherein, based on the flow direction of the reaction materials, the rib-type partition member is located upstream of the porous screen. The property parameters of the gaseous product stream obtained are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com