Preparation method of high-purity cyclopentene

A technology of cyclopentene and cyclopentadiene, which is applied in the field of cyclopentene preparation, can solve the problems of diolefin raw material polymerization, difficult to handle, and affect catalyst life, so as to reduce the difficulty of separation, prolong life, and reduce equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

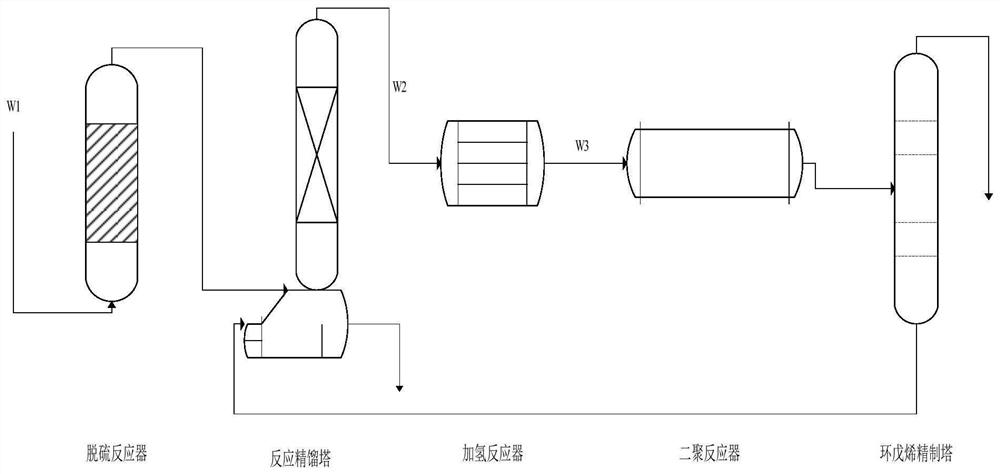

[0028] The technological process of embodiment 1~10 sees figure 1 , the raw material W1 first converts light sulfur into heavy sulfur through the desulfurization reactor, and then enters the reactive distillation tower for depolymerization reaction to obtain the depolymerization product W2. The theoretical plate number of the reactive distillation tower is 30, and the top of the tower is obtained High-purity CPD finished product W3, heavy component impurities are regularly discharged from the tower kettle. W2 enters the fixed bed reactor for hydrogenation to obtain the hydrogenated product W3, which is polymerized in the dimerization reactor and separated by the cyclopentene refining tower to finally obtain the finished cyclopentene W4.

[0029] The reaction process is as follows:

[0030] (1) The raw material ethylene cracking C9 fraction enters the desulfurization reactor for desulfurization reaction, and converts light sulfur into heavy sulfur;

[0031] (2) The material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com